Choosing the wrong jar labeling machine can lead to mislabeled jars, production delays, and increased costs. Picking the right machine is crucial to making sure you have accurate and efficient labeling.

Selecting the right jar labeling machine depends on production speed, jar size compatibility, the type of label material you are using, and whether you need customization features. You also need to think about the precision of the machine, how easy it is to integrate, and the long-term cost of operation.

Let’s break these down to help you decide which machine you need.

Identify Your Production Speed Requirements

One of the first things you need to figure out when you’re trying to decide which machine you need is how many jars you have to label per minute or per hour. Machines for high-production environments label lots of jars per minute, sometimes up to 200. If you’re a little slower, you might only need to label 30 jars a minute.

High-speed jar labeling machines, like those offered by LabeMachine, are specifically designed to maintain accuracy even at fast speeds. Depending on your production line’s pace, you’ll want to ensure that the machine can keep up without sacrificing precision or leading to bottlenecks in your operations.

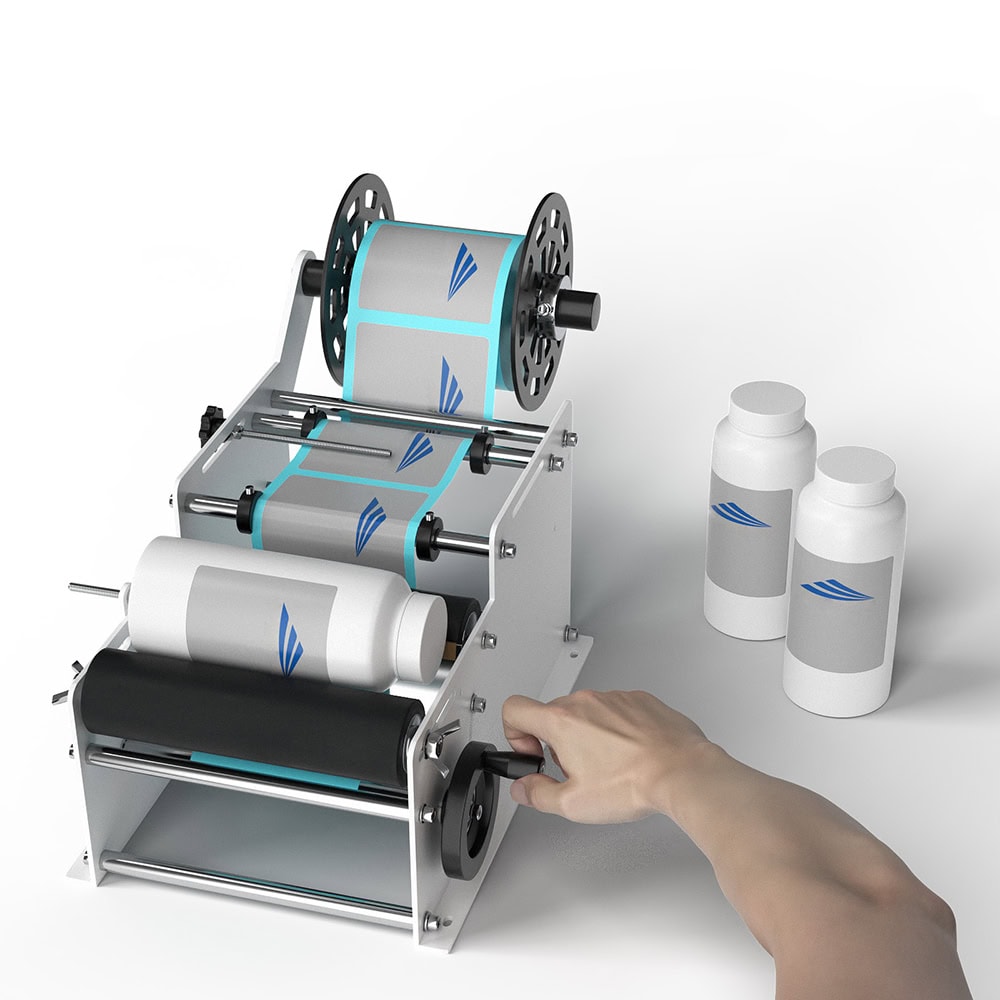

Compatibility with Jar Size and Shape

Another thing to consider is how the machine works with the size and shape of your jars. It’s important to make sure the machine can handle the different sizes and shapes of jars you use in your business.

Many jar labeling machines have settings that allow you to adjust them to handle different sizes and shapes of jars. You might need a machine with adjustable guides or rollers if you’re going to have a wide variety of jars. This feature allows you to run anything from little cosmetic jars to big, old food containers without changing a bunch of stuff.

Labeling Precision and Accuracy

The precision of the label is important because it affects how your product looks and whether you comply with industry standards. If your label is all cattywampus on your jar, it might make your product look bad, or you might get in trouble in some industries.

Machines with servo motor systems put labels on with high precision, usually within ±0.5mm accuracy. If you’re in a business where you need your product to look good and have the label in the same place every time, like cosmetics or premium food products, you need a high-accuracy machine. Many modern machines, including the ones from LabeMachine, are really good with precision.

Label Material Compatibility

Different types of labels have different characteristics that can affect how they stick to your jars. You need to make sure the machine you buy can handle the type of label you’re going to use. Some machines are set up to work with certain types of labels. If you select the wrong one, you may have problems with the labels not sticking or getting all wrinkled up.

If you’re going to be using special materials like clear labels, you might need a machine with fancy sensors or custom options to handle those kinds of materials correctly. Machines that can handle a variety of label materials give you more flexibility on your production line.

Ease of Integration into Production Lines

How the machine works with your production line is important. Whether you’re upgrading an existing system or putting in a new production line, you need to make sure the machine works with everything else.

Look for machines that have flexibility in how they integrate with the belts, where the sensors are, and how they talk to your other stuff. A machine that works well with the rest of your line will save you time when you set it up and help you make product.

Maintenance and Support

Think about what’s involved in taking care of the machine when you’re deciding which one to buy. A machine that’s easy to take care of will save you time and help you keep making product. Look for a machine that has parts you can get to and instructions on how to take care of it.

Make sure you have good customer support and access to parts to keep the machine running. A machine from a reputable company like LabeMachine will give you good support after you buy it.

Customization Features

In some industries, you might need to customize how the label goes on the jar. You might need to put two labels on the jar, turn the label a certain way, or use different sized labels. Customization features can make a big difference in how good your product looks and how fast you can make it.

Many labeling machines have settings for multiple label applications and features that let you adjust how the label goes on the jar. You might need a machine with these features so you can put the label on the jar the way you want it.

Energy Efficiency

The amount of power the machine uses is important because it affects how much it costs to run your machine and how green your company is.

When you compare machines, look for things like energy-saving modes, special designs that use less power, or certifications that show the machine is energy-efficient. If you’re making a lot of product, this can add up to a lot of money.

Budget Considerations

Balancing your budget with your production needs is key when you’re trying to decide which machine to buy. It might be tempting to buy the cheapest machine you can find, but it might not label your jars fast enough, or the labels might not be right, or it might break all the time.

Buying a good machine that labels your jars as fast as you need them and puts the label on right is really important. Think about how much money you’re going to save by not having your machine break down all the time, your labels being wrong, or not being able to make enough product.

Compliance and Certification

If you’re in a business where you have to do things a certain way, like food or drugs, you need to make sure the machine you buy meets certain standards. Look for things like CE or ISO certifications to help you make sure your product is safe and clean and your machine works the right way.

Picking a machine from a manufacturer that pays attention to these things will help you sleep at night and not get in trouble.

Conclusion

Choosing the right jar labeling machine is a balancing act between speed, precision, compatibility, and long-term costs. If you carefully consider each of these factors, you will have a smooth production process that cranks out product and has little downtime.