Home » Labeling Machine

Explore our diverse range of Labeling Machines designed to meet various industrial labeling needs. Browse each category to find the perfect machine that suits your operational needs.

A labeling machine is a device used to apply labels accurately to various products, ranging from bottles and boxes to packages and containers. These machines streamline the labeling process, enhancing efficiency and precision.

Labeling machines come in different types, including automatic, semi-automatic, and manual variants, each catering to specific needs. They can operate independently or be integrated into a production line, working seamlessly with upstream filling machine and downstream packaging machine to ensure a fully automated production process.

Whether you need to label products individually or as part of a complete system, our advanced labeling solutions can meet your requirements.

Our range of labeling machines caters to various product needs.

We provide wire labeling machines for cylindrical items like wires and cables, bottle labeling machines for round products such as bottles and cans, and flat labeling machines for surfaces like cartons and boxes. We also offer corner wrap labeling machines for labeling multiple surfaces at once.

Additionally, we specialize in creating customized labeling solutions to fit unique requirements. No matter your product type, contact us for the ideal labeling machine to enhance your production process.

Precision is a key indicator of a labeling machine’s performance. Our machines offer varying precision levels depending on their function, ranging from ±0.3mm to ±1mm. If you require high precision for your labeling needs, please specify your requirements in your email. This helps us provide accurate quotes and tailored solutions to meet your exact specifications.

The speed of a labeling machine is a crucial factor in determining production output. Our labeling machines at LabeMachine operate at speeds ranging from 35 to 300 pieces per minute, depending on the specific model. We can also customize the speed to meet your particular production requirements. For tailored solutions, please let us know your speed needs, and we’ll provide the perfect fit for your operations.

Understanding the key components of our labeling machines will help you appreciate their advanced design and functionality. These elements work in unison to deliver high-quality labeling performance. Here are the four main components:

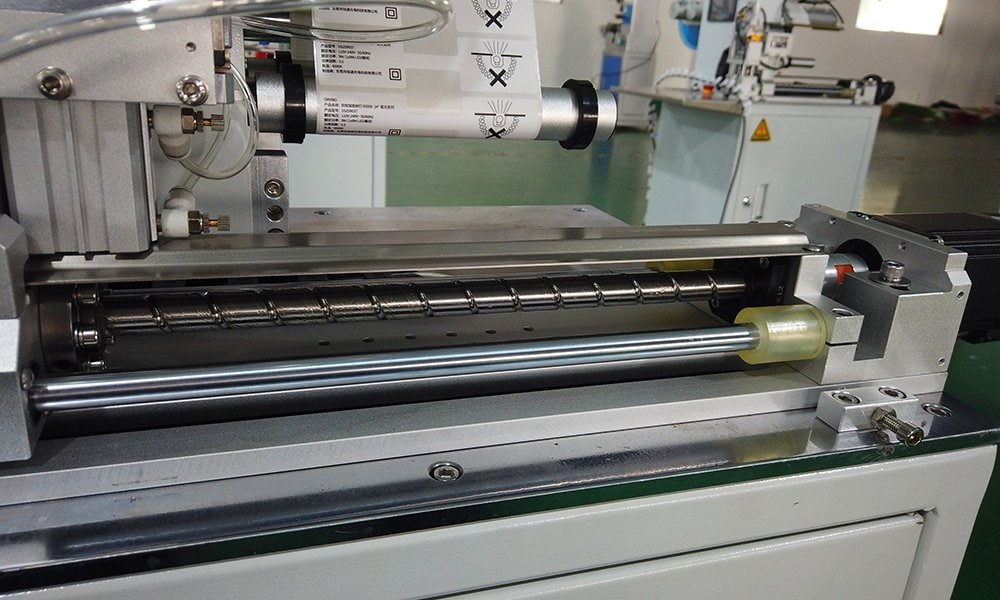

The traction mechanism is designed to control the movement of the label material through the machine, ensuring precise feeding and minimal misalignment.

This system manages the tension and speed of the label roll, preventing issues like wrinkles or breaks. Advanced traction controls allow for smooth operation at both low and high speeds, accommodating different production rates. This mechanism’s accuracy is vital for maintaining the integrity of the labeling process, particularly for high-speed applications.

It ensures that each label is presented at the right time for perfect application. Efficient traction reduces material waste and enhances overall productivity.

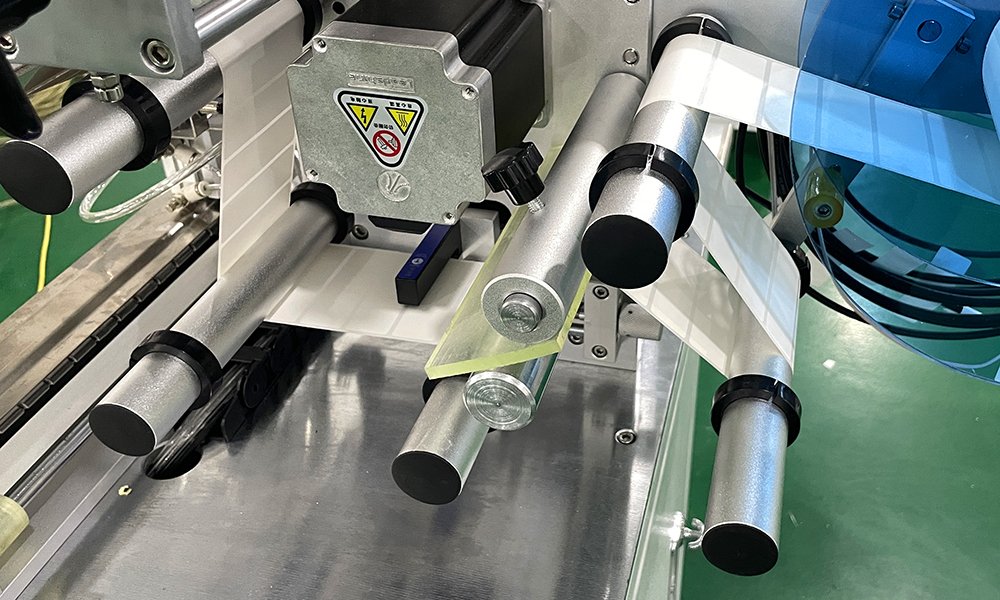

The label sensor is a critical component that detects the exact position of each label, ensuring precise placement on every product.

Using advanced optical or ultrasonic technology, our sensors can identify a wide range of label types and materials, including transparent or opaque labels. This precision guarantees that labels are applied consistently and accurately, crucial for maintaining product quality and compliance. The sensor system can be adjusted to accommodate different label sizes and gaps, providing flexibility for various labeling tasks.

Real-time adjustments help to minimize downtime and keep the production line running smoothly. Accurate sensing technology is essential for achieving high-quality, repeatable labeling results.

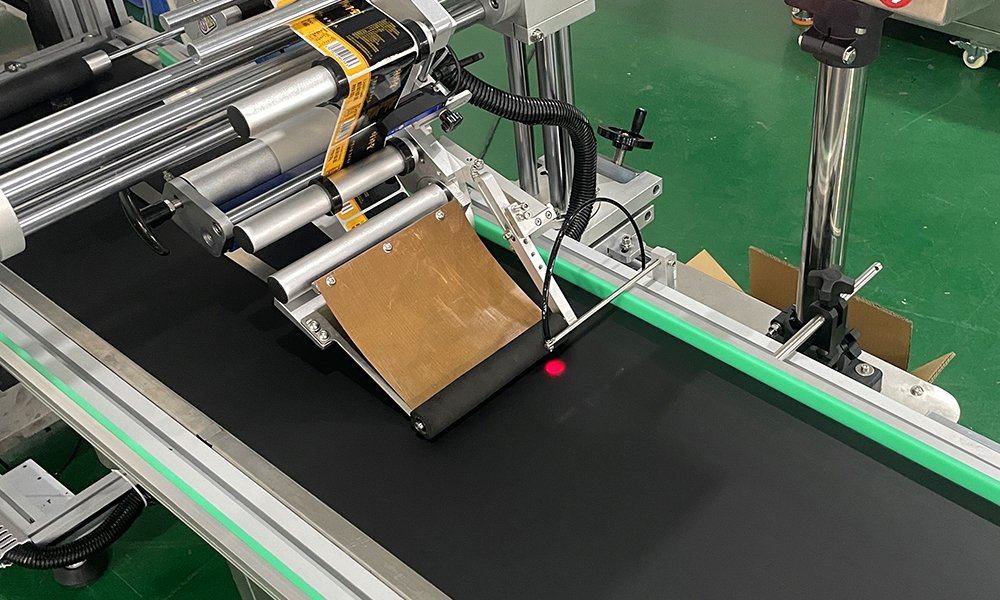

The labeling mechanism is responsible for applying the labels onto the products with precision and consistency.

It operates with high accuracy, ensuring that labels adhere securely and are free from bubbles or misalignment. Our labeling systems can be tailored to handle different label shapes and sizes, making them versatile for various applications. The mechanism can apply labels to flat, cylindrical, or even irregular surfaces, providing a professional finish every time.

Adjustable settings allow you to control the pressure, speed, and angle of application to meet specific labeling requirements. This adaptability ensures that every label is applied perfectly, enhancing the appearance and functionality of your products.

The adjustment mechanism allows for fine-tuning of the labeling process to accommodate different products and labeling specifications. It provides the flexibility to adjust the machine’s settings, including label positioning, speed, and application angle, to suit your production needs.

This capability is crucial for quickly switching between different products or label designs without significant downtime. Our adjustment systems are user-friendly, enabling easy and precise modifications to optimize performance. They ensure that the labeling process remains efficient and effective, even as requirements change.

By offering comprehensive control over the labeling operation, the adjustment mechanism helps maintain high-quality standards and operational efficiency.

You may have some questions about labeling machines, and we’ve collected some of the most common ones so you can get them answered right from the start!

Yes, we can provide a video demonstrating the labeling results. For a more accurate demonstration, we recommend that customers send us their samples so we can label them and show the precise results.

We use secure packaging and reliable freight services to ship our machines globally. For heavy equipment, we recommend sea freight for cost-effectiveness.

Yes, we offer customization options to meet specific requirements, including size, labeling speed, and special functionalities.

The standard lead time for our labeling machines is usually 3-4 weeks, depending on the complexity and customization needed.

Our machines support a wide range of label types, including paper, plastic, and foil labels, suitable for different shapes and surfaces.

We offer comprehensive after-sales services, including installation support, troubleshooting, maintenance, and spare parts supply. Additionally, our labeling machines come with a one-year free warranty to ensure peace of mind for our customers.

Contact our customer service team for support. We provide remote assistance and, if necessary, dispatch technicians for on-site repairs.

All equipment is securely packaged in wooden crates, with the machine surfaces wrapped in protective film to prevent dust and moisture. This ensures safe and clean delivery, maintaining the integrity and quality of the machinery during transit.

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more