A lot of businesses struggle with what label to put on their stuff. This can create operational inefficiencies and compliance problems. It can also cost you more money, put you at risk for recalls, and make you really confused about where all the stuff in your warehouse is supposed to go.

Manufacturers produce various label types, including pressure-sensitive labels, shrink sleeve labels, wrap-around labels, heat transfer labels, and in-mold labels, each serving different industrial purposes such as product branding, identification, and regulatory compliance.

Now, let’s talk about the different labels you can put on your stuff.

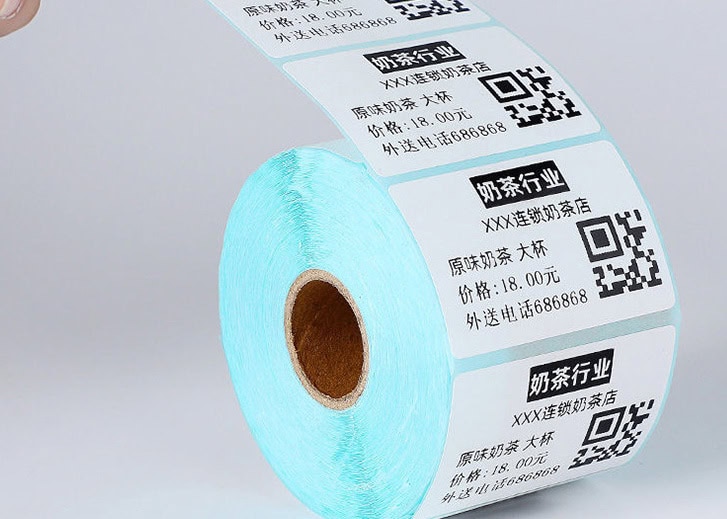

Pressure-Sensitive Labels

How to put a label on your stuff. The pressure-sensitive label is one of the most common types of labels you will see on things in packages. They are called pressure-sensitive because you apply pressure to the label to make it stick to your stuff. You don’t need heat, and you don’t need water. You just need to put pressure on it. These labels can be put on all kinds of things like plastic, glass, and metal, which is why they are so popular.

For example, you will see pressure-sensitive labels on bottles and containers. You can put all kinds of different information on them like your brand, a barcode, and information you have to put on there that is regulated, like nutrition facts. Some of the labels you might put on a product include a brand label or a descriptive label.

Shrink Sleeve Labels

The shrink sleeve label is another type of label you see on things. It is a label made out of plastic that you heat up, and it shrinks to fit the shape of your container.

The cool thing about shrink sleeves is that they wrap all the way around your container. This gives you the ability to put a lot more information on your package, more branding, and more visual design.

You will see these labels in the beverage industry, in the cosmetic industry, and in the household goods industry. For example, a lot of bottles in the beverage industry have shrink sleeves on them so they can have branding all the way around the bottle.

You will also find grade labels on shrink sleeve labels. This is common in industries where you need to make sure the grade of the product, the batch information, or the expiration date is highly visible.

Wrap-Around Labels

A wrap-around label is a label that goes all the way around your stuff. These are commonly used in high-speed packaging operations. You will see wrap-around labels mostly on cans and bottles in the food and beverage industry. You can put a lot of information on these labels like the ingredients in your product, a barcode, and your brand.

For example, on a can of soda, the entire label wraps around the can. On the label, you see the company’s logo, the name of the soda, and nutritional information. These labels are very durable, cost-effective, and stick very well to your stuff, even in the refrigerator or cooler. If you need a label that will stick on your stuff and not come off, this is a good option for you.

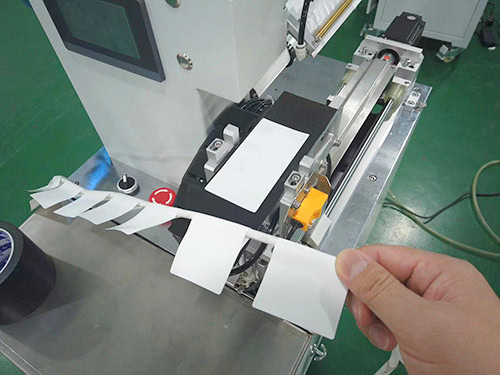

Heat Transfer Labels

The heat transfer label is what you want to use when you need something that sticks to your stuff and doesn’t come off. You put these labels on your stuff with heat and pressure, and the ink on the label gets embedded into the surface of your stuff. This label is great when you need something that is not going to come off your stuff.

A lot of times, you see these labels used for a description label. This is where you need to put a lot of information on the label about your product that is going to be on your product for a long time. For example, you might have a label that has a lot of words on it on a product that is going to be on there for a long time. An example of this might be a warning sign, a model number, or how to use it.

In-Mold Labels

An in-mold label is a label that you put in the mold when you make the plastic container. When the plastic cools down and hardens, the label is stuck in the plastic. This makes a really nice-looking label that does not come off your stuff. You see these labels in the food industry, the cosmetic industry, and the household goods industry.

For example, you see these labels on plastic food storage containers. You will also see these labels on high-end consumer goods. These labels are great when you have a product you want to look really nice.

Customized Labels for Specialized Needs

There are also lots of different kinds of labels you can put on your stuff. You can make a special label to go on your stuff. These labels can do all kinds of things from helping you keep track of your stuff with a barcode system to making sure nobody fakes your stuff. You will need custom labels if you are in an industry where you have to do something special with your label.

For example, you might need a special label that tells people how to use your product. This could be a label that tells someone how much of a drug to take or it could be a label that tells you not to drink something because it will kill you. You might also need a special label to tell people what grade your product is or what batch it came from.

Conclusion

People who make labels have all kinds of labels you can put on your stuff. You need to pick the right label to put on your stuff.