When labels fail to come out properly from a corner labeling machine, it can halt your production line. This leads to delays, inefficiency, and potential product damage. To avoid these costly consequences, it’s crucial to understand the causes and solutions for label dispensing issues.

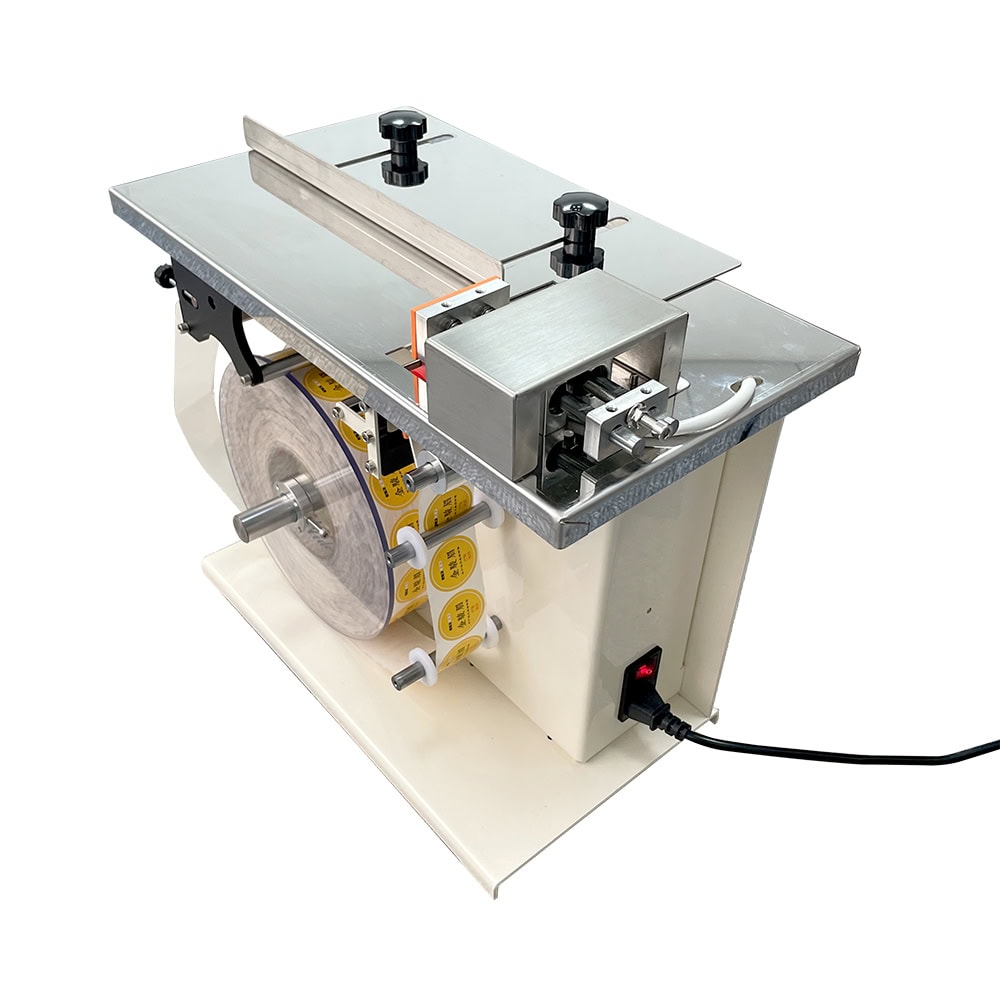

What is a Corner Labeling Machine?

A corner labeling machine is designed to apply labels to the corners of products, particularly in industries like packaging and manufacturing. It is commonly used for items that require precise corner labeling, such as boxes, bottles, or containers. This machine ensures that labels are applied accurately and efficiently, contributing to streamlined operations.

Why Can’t the Labels Come Out Properly?

There are several reasons why labels might not come out properly from the corner labeling machine. These issues are often related to mechanical faults, settings misalignments, or label quality. Below are the common causes:

- Label Misalignment: Labels may not be dispensed correctly if they are not properly aligned within the machine. This could be due to a misfeed or incorrectly adjusted rollers.

- Incorrect Label Size: Using labels that do not match the specifications required by the machine can lead to poor label handling and jams.

- Machine Settings: Sometimes, the machine settings may be incorrect, such as speed settings or application pressure. This can affect how labels are fed and applied.

Solution:

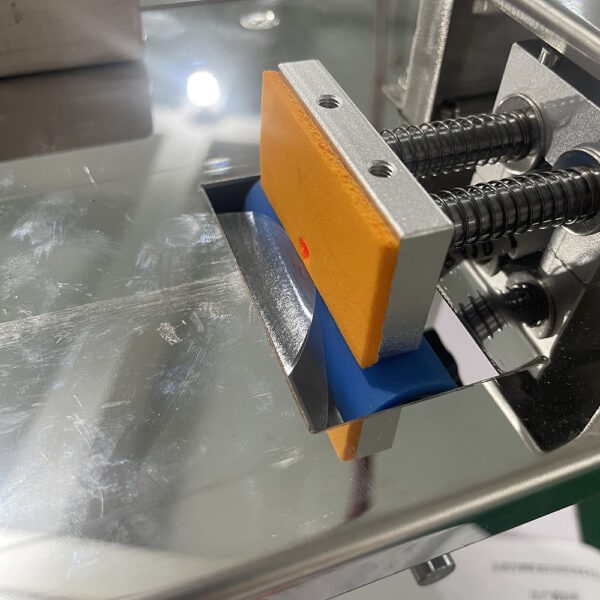

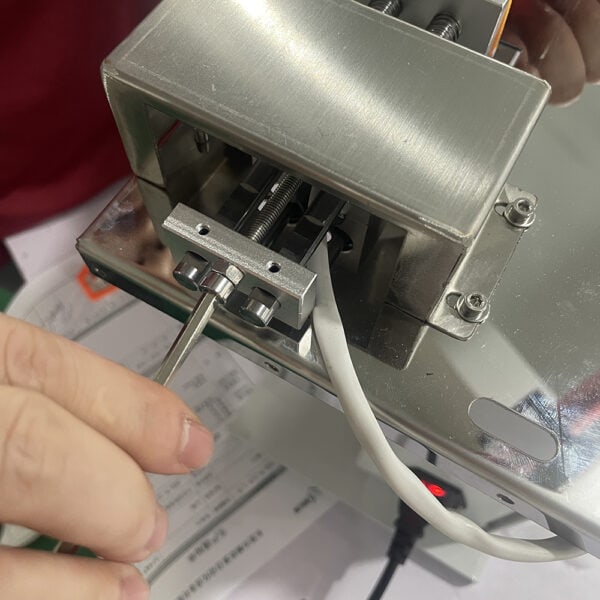

Generally we need to adjust the position of the spring mechanism, adjust the screws to make them loose, move the spring mechanism backward to solve the problem of stuck labels.

How to Troubleshoot and Resolve the Issue?

If your corner wrap labeling machine is not dispensing labels properly, take immediate action to troubleshoot the problem:

- Pause the Machine: First, stop the machine to prevent further damage or label wastage.

- Check for Jams: Inspect the label roll and feeding path for any blockages or misalignments that could be causing a jam.

- Verify Label Size and Type: Ensure that the label being used matches the specifications for your labeling machine.

- Inspect Machine Settings: Check the settings for speed, pressure, and positioning. Make necessary adjustments based on your product and label size.

- Contact After-Sales Support: If the issue persists and you are unable to fix it, reach out to customer support for professional assistance.

Why Do Large Labels Get Stuck?

Large labels are often more prone to jamming in the corner labeling machine due to their size and weight. As these labels are dispensed, gravity can cause them to tilt or lose their vertical position. This makes it difficult for the label to stand upright, which can cause the label to get caught or stuck in the machine.

To prevent this, ensure that larger labels are fed in a way that supports their weight. Consider using a label printer with specific settings for large labels, or adjust your machine’s speed and pressure to allow for smoother label dispensing.

How to Prevent Label Jams?

Preventing label jams requires a combination of regular maintenance, proper machine setup, and high-quality labels:

- Regular Maintenance: Consistent cleaning and inspection of the machine can help avoid buildup or wear that leads to mechanical failure. Regularly check the rollers and label guides to ensure smooth operation.

- High-Quality Labels: Use quality labels that are suited for your specific labeling machine. Labels that are too thick or have adhesive issues are more likely to cause jams.

- Machine Calibration: Calibrate your machine to ensure that the correct label size and application pressure are set. This can prevent misfeeds and ensure the smooth dispensing of labels.

Additional Tips for Smooth Label Dispensing

- Proper Label Storage: Store labels in a cool, dry place to maintain their quality. Exposure to heat or humidity can cause labels to warp or lose adhesion, leading to jams.

- Avoid Overloading the Machine: Overloading the machine with too many labels or improper rolls can cause the machine to malfunction. Always follow the manufacturer’s recommended label capacity.

Conclusion

Labeling problems, especially in machines like the corner labeling machine, can cause significant production delays. By understanding common causes such as label misalignment or incorrect settings, and taking steps to properly maintain the machine, you can ensure that your labeling process runs smoothly.

If problems persist, don’t hesitate to seek assistance from experts. For more information on troubleshooting or customizing your labeling system, contact us today.