Printing and labeling are crucial in packaging, but confusion between the two leads to inefficiencies and poor decision-making. Understanding their distinctions enhances production and brand presentation.

Printing directly applies ink or dye to a surface, creating a design or text on the product. Labeling involves attaching a pre-printed or blank adhesive material to a surface, offering versatility and convenience in customization.

Understanding their key differences helps in choosing the right solution for branding, compliance, and operational efficiency.

Definition and Process of Printing

Printing refers to the process of directly transferring ink, dye, or other pigments onto the surface of a product. Methods like screen printing, digital printing, and offset printing ensure designs, logos, or textual information are embedded into the surface, offering durability and permanence.

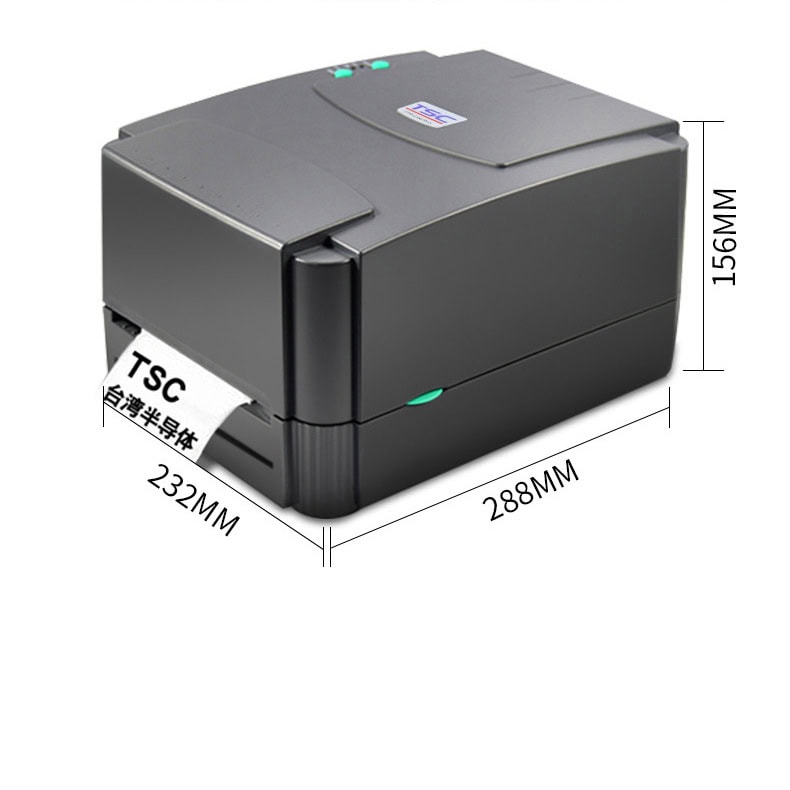

For example, industrial label printers play a pivotal role in creating labels on-demand but differ from direct printing as they involve adhesive materials. Printing is ideal for mass production, such as branding logos on PET bottles or food trays.

Definition and Process of Labeling

Labeling involves affixing pre-printed or blank adhesive materials, such as stickers or tags, onto products. This method provides unmatched flexibility, allowing businesses to customize designs or add essential details like barcodes, batch numbers, and expiration dates. Equipment such as rolling bottle labeling machines and flag labeling machines facilitates the precise application of labels on different product shapes and surfaces.

Labeling is often preferred in industries where compliance with dynamic regulations is essential, like food, beverage, and pharmaceuticals.

Materials Used in Printing vs. Labeling

- Printing: Utilizes inks and dyes compatible with a variety of surfaces such as plastics, metals, and paper.

- Labeling: Uses adhesive-backed materials, including paper, plastic, or fabric, offering versatility for adjustments or removal.

Products such as flat labeling machines accommodate various label types, catering to diverse industrial needs.

Applications and Suitability

- Printing: Best for permanent branding directly on products, such as company logos on glass bottles.

- Labeling: Ideal for variable information like serial numbers, barcodes, or promotional tags. Positioning bottle labeling machines enable accuracy for high-speed labeling in packaging lines.

Advantages of Printing

- Durability: The printed text or design becomes an integral part of the surface, ensuring longevity.

- Cost Efficiency: High upfront costs are balanced by low per-unit costs in large-scale production.

Advantages of Labeling

- Customization: Labels can easily be updated or modified to meet evolving requirements.

- Versatility: Applicable to a wide range of surfaces and product types using machines like bottle labeling machines or corner wrap labeling machines.

Cost and Speed Differences

- Printing: Requires significant initial investment for setup but is cost-effective for bulk production.

- Labeling: Lower startup costs but higher operational costs for large volumes due to adhesive materials and machinery.

Technology and Equipment

Printing utilizes technologies like digital and screen printing presses. Labeling, on the other hand, relies on dedicated equipment such as shrink wrap machines and vacuum packaging machines, often integrated into automated production lines.

Design and Customization Options

Printing designs are limited by surface compatibility and ink durability. Labeling provides more freedom, allowing businesses to design unique labels with advanced details using customized labeling machines.

Environmental Impact

- Printing: Can generate waste due to limited recyclability of printed surfaces.

- Labeling: Offers environmentally friendly options, such as recyclable adhesive materials, though adhesives can complicate the recycling process.

Conclusion

Understanding the distinction between printing and labeling helps businesses choose the right method for efficiency, branding, and compliance needs. Whether you rely on packaging machines or focus on innovative labeling solutions, tailoring the choice to your operation’s demands will maximize results. Learn more about our labeling machine solutions to enhance your production process.