The diverse types of taping machines available today can confuse buyers and lead to inefficient selections, hindering productivity and increasing costs. Understanding these classifications ensures optimal performance and alignment with industrial requirements.

Taping machines are classified by operation type (manual, semi-automatic, automatic), application (industrial, packaging, electrical), and taping methods (spiral, longitudinal, wrapping).

Taping machines are essential across multiple industries. Recognizing their categories can save time, reduce costs, and improve process precision.

Overview of Taping Machines

Taping machines are specialized equipment designed to apply adhesive tape in various industrial processes. Their primary role is to enhance productivity, ensure uniformity, and reduce labor costs. From bundling wires to packaging goods, these machines cater to specific operational demands.

Benefits of Using Taping Machines

- Efficiency: Automates repetitive tasks, reducing human error.

- Precision: Ensures uniform taping for better product durability and aesthetics.

- Versatility: Suitable for applications like electrical insulation, cable wrapping, and packaging.

Classification by Operation Type

Manual Taping Machines

Manual taping machines are entirely operator-dependent and are best suited for low-volume or unique applications. They are compact and economical but limited in output.

Semi-Automatic Taping Machines

These machines balance manual input with automated features like tape feeding or cutting. Ideal for medium-scale operations, they offer a cost-effective way to boost productivity without full automation.

Automatic Taping Machines

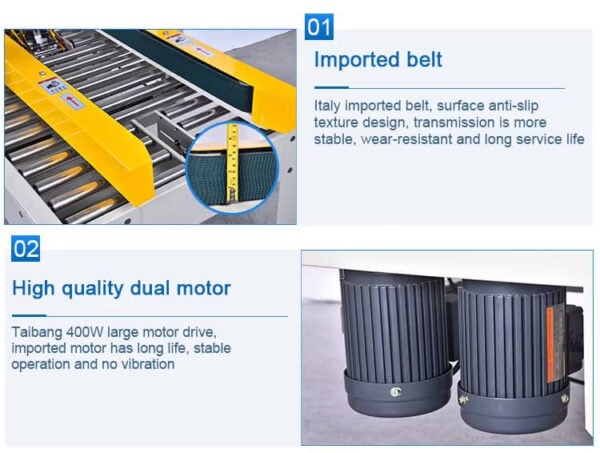

Fully automated machines handle high-speed operations with minimal supervision. They are essential for large-scale industries such as packaging machine and filling machine, where speed and accuracy are paramount.

Classification by Application

Industrial Taping Machines

Used in heavy-duty settings, such as manufacturing lines, these machines are engineered for durability and high performance. Applications include cable and wire wrapping.

Packaging Taping Machines

Found in logistics and warehousing, packaging taping machines seal boxes and cartons efficiently. They are often integrated with systems like the shrink wrap machine for additional security.

Electrical Taping Machines

Designed for insulation and circuit protection, these machines ensure precision in wire wrapping and electronic component assembly.

Classification by Taping Method

Spiral Taping Machines

These are common in the electrical and cable industries. Spiral wrapping covers wires and cables for insulation or bundling purposes, providing uniform coverage along the length.

Longitudinal Taping Machines

These machines apply tape in a straight line, often used for seams or edges in industrial products.

Wrapping Taping Machines

Used for protective packaging, wrapping machines ensure a secure layer of tape around products like pipes, cables, or irregularly shaped items.

Key Features and Specifications

- Accuracy: Ranges from ±0.3mm to ±1mm depending on the machine type.

- Speed: Operates at 10 to 1500 pieces/hour based on the application.

- Compatibility: Supports tapes of varying widths, thicknesses, and adhesive strengths.

Industry-Specific Taping Machines

Wire and Cable Taping Machines

Specialized for electric wires, telephone lines, and fiber optics, these machines maintain precise insulation and bundling.

Packaging Taping Machines

Frequently paired with devices like vacuum packaging machines, these machines improve operational efficiency in logistics.

Customizable Taping Machines

Tailored solutions are available for unique industry needs, such as multi-layer taping or environmentally resistant applications.

Trends in Taping Machine Technology

- Automation and AI: Enhances precision, reduces waste, and simplifies operation.

- Sustainability: Increasing use of eco-friendly adhesives and biodegradable tapes.

- IoT Integration: Real-time monitoring and control of machine functions through connected systems.

Conclusion

Understanding the classifications of taping machines helps businesses select the right equipment for their needs, maximizing productivity and minimizing operational inefficiencies.