Effective cable marking is crucial for maintaining safety, efficiency, and organization in various industries. Without proper identification, cables can become difficult to manage, leading to potential hazards and time-consuming troubleshooting. The right cable marking method can streamline processes, reduce errors, and improve system reliability.

The best way to mark a cable is to use a reliable and durable labeling method tailored to the application. Options such as self-laminating labels, heat shrink tubing, or advanced flag labeling solutions provide versatile and long-lasting results in diverse environments.

To help you decide on the best method for your needs, let’s explore the available options and their applications in detail.

Why Cable Marking Matters

Cable marking plays a vital role in many environments, from industrial settings to office networks. Proper labeling ensures compliance with industry regulations, facilitates maintenance, and reduces downtime. Without clear cable identification, workers may struggle to trace connections, repair issues, or reconfigure systems.

Industries such as telecommunications, healthcare, and manufacturing depend on robust cable labeling solutions to maintain operations and safety standards.

Common Challenges in Cable Marking

Before selecting a cable marking solution, it’s important to understand the challenges. Environmental factors like high temperatures, humidity, and mechanical stress can compromise the durability of labels. Inadequate adhesion or poorly chosen materials may lead to fading, peeling, or misalignment.

Manual methods, though inexpensive, often lack the precision and longevity required for demanding applications. Automated solutions like an industrial label printer provide a more reliable alternative.

Overview of Cable Marking Methods

Manual Methods

Traditional techniques, such as handwritten tags or adhesive tape, are cost-effective and simple but prone to errors. They are best suited for temporary or low-volume applications.

Printed Labels

Using a label printer to create adhesive labels improves legibility and uniformity. These labels can be applied directly to cables and are suitable for environments with minimal wear and tear.

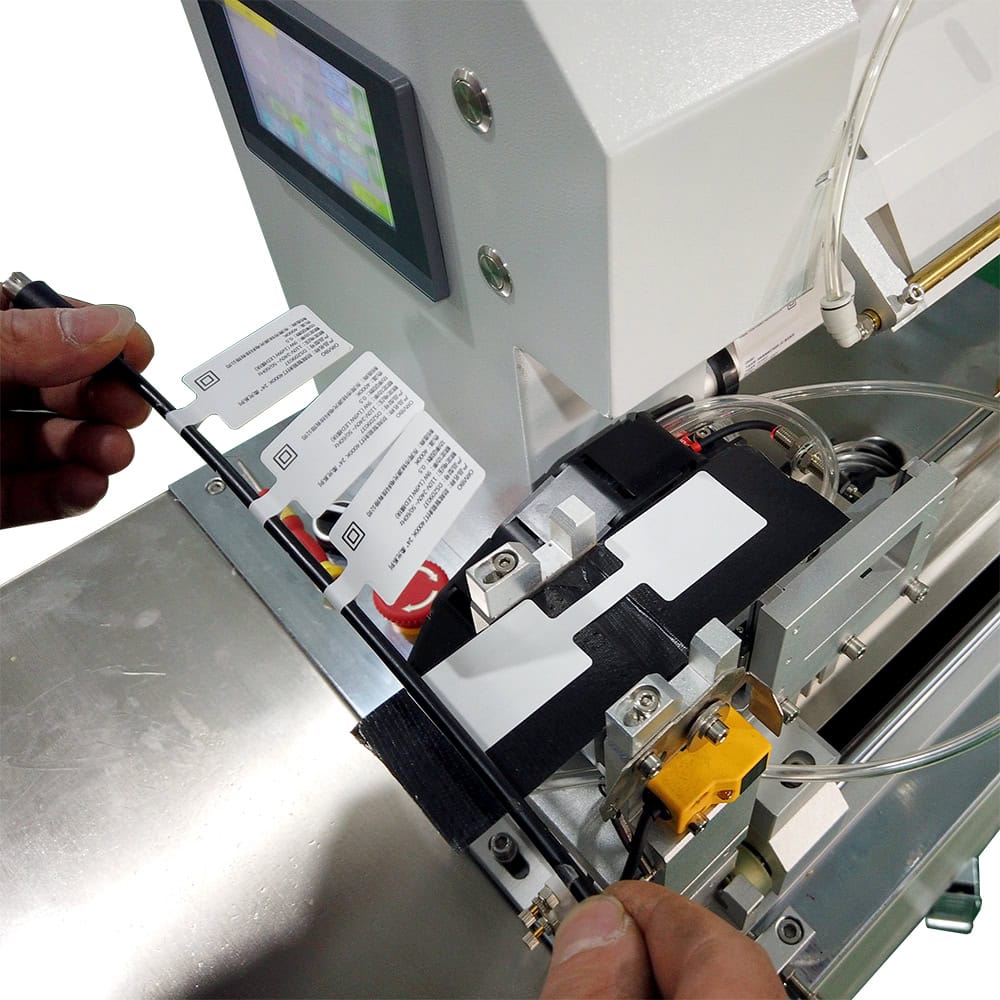

Flag Labels

Flag labels wrap around cables and provide visible identification from all angles. They are ideal for applications requiring easy-to-read information on compact cables or wires.

The Role of Self-Laminating Labels

Self-laminating labels are a popular choice for environments exposed to moisture, grease, or abrasion. These labels feature a protective layer that shields printed information, extending their lifespan. They are especially effective in industries like food processing, where durable labeling is critical for compliance.

Heat Shrink Tubing for Permanent Labels

Heat shrink tubing offers a secure, permanent marking solution. When heated, the tubing shrinks to tightly encase the cable, protecting the label from mechanical damage. This method is ideal for high-temperature or high-vibration environments.

Flag Labels for Cables

Flag labels are versatile and suitable for identifying small wires and cables where space is limited. They provide an accessible display of information without requiring the cable to be rotated. This feature is particularly useful in densely packed systems.

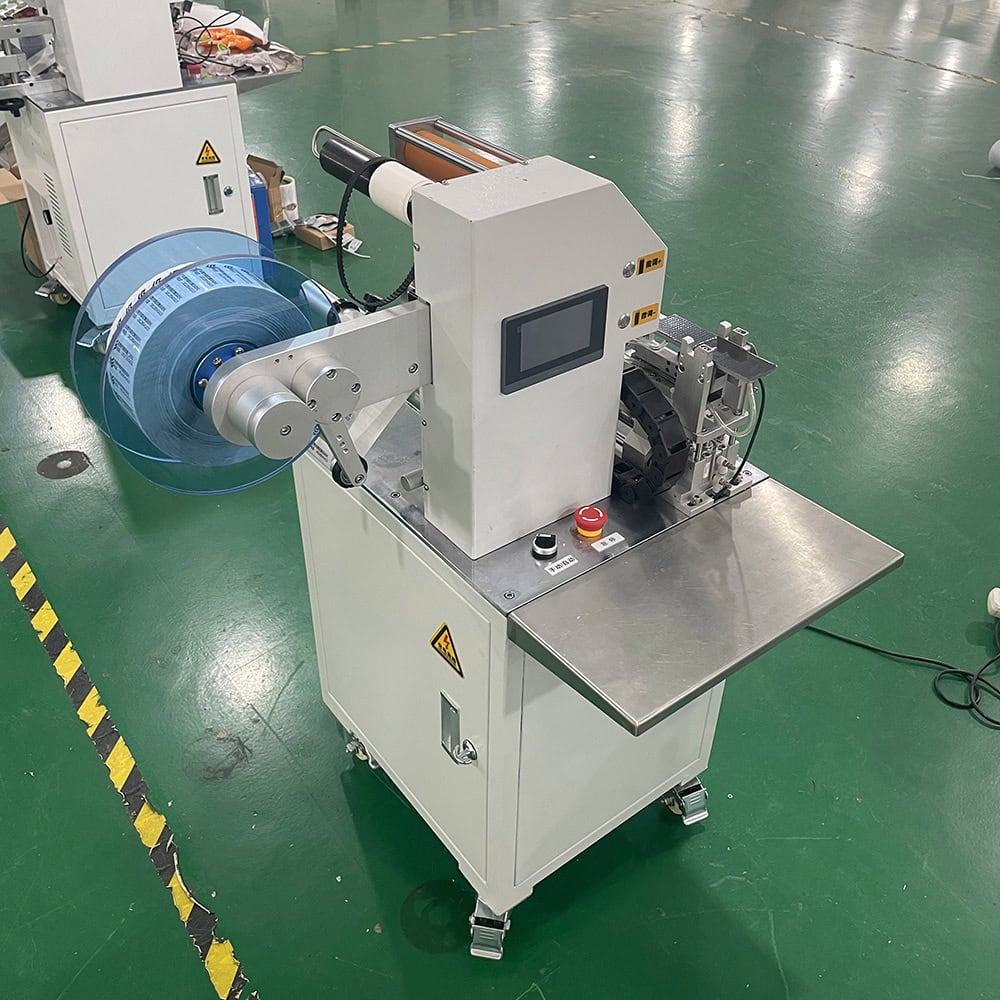

The Rise of Automated Cable Marking Solutions

For large-scale operations, automated systems like a flag labeling machine or an advanced industrial labeling machine offer unmatched efficiency. These machines can handle high volumes, maintain consistency, and reduce human error. Automation also ensures that labels meet strict industry standards for legibility and placement.

Choosing the Right Labeling Method

The best cable marking method depends on the specific application. Consider factors such as environmental conditions, cable size, and the required durability of the labels. For example:

- Use heat shrink tubing for extreme environments.

- Opt for self-laminating labels for moderate exposure to wear.

- Choose automated systems for high-volume operations requiring precision.

Tips for Effective Cable Tagging

- Plan ahead: Design labels with clear and concise information.

- Use color coding: Differentiate cables by function or type.

- Test materials: Ensure compatibility with your cables and environment.

Future Trends in Cable Labeling

Emerging technologies, such as RFID tags and eco-friendly materials, are shaping the future of cable marking. Automation continues to advance, with systems like a customized labeling machine offering tailored solutions for unique requirements. These innovations promise greater efficiency and sustainability in cable management.

Conclusion

Choosing the right cable marking method is essential for maintaining order and safety in any system. From self-laminating labels to automated flag labeling solutions, there is a wide range of options to suit diverse needs. Investing in reliable labeling solutions ensures long-term benefits, saving time and reducing operational risks.