Stretch film, a flexible plastic wrap, has become an essential tool in various industries, serving as a versatile solution for bundling, securing, and protecting goods.

Commonly made from linear low-density polyethylene (LLDPE), stretch film is renowned for its elasticity and strength, making it an excellent choice for safeguarding products during storage and transit. Unlike shrink wrap, which requires heat to secure items, stretch film relies on its natural cling and tension to provide protection and stability.

Types of Stretch Film

Hand Stretch Film

Hand stretch film is typically applied manually, making it suitable for smaller loads or applications where full automation isn’t required. It provides adequate cling and strength, ideal for light-duty packaging tasks.

Machine Stretch Film

Machine-applied stretch film is designed for automated systems, allowing high-volume operations to efficiently wrap and secure pallets. It’s generally more durable and consistent in thickness, ensuring greater load stability.

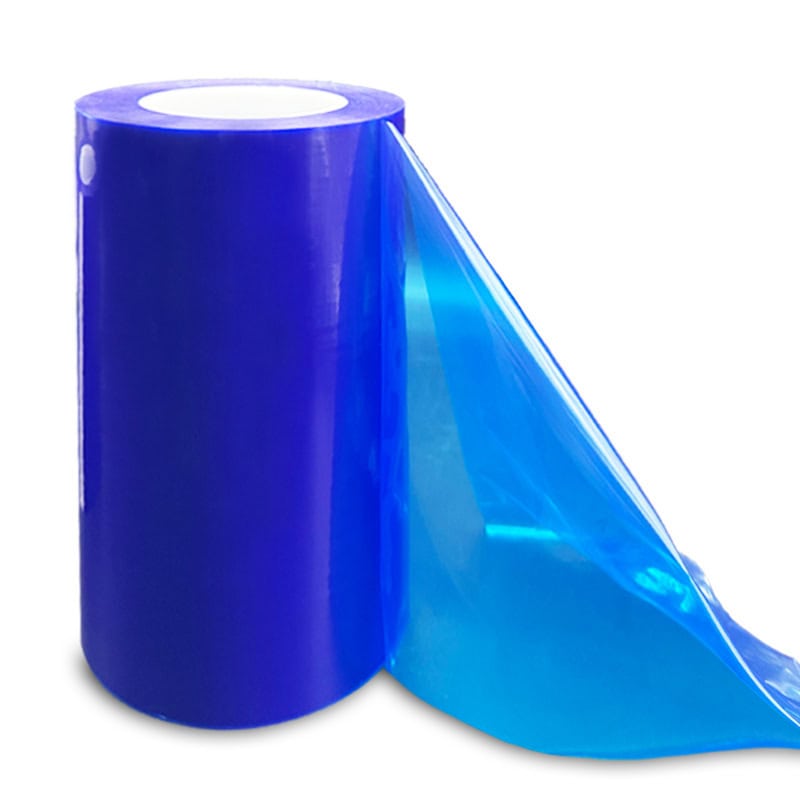

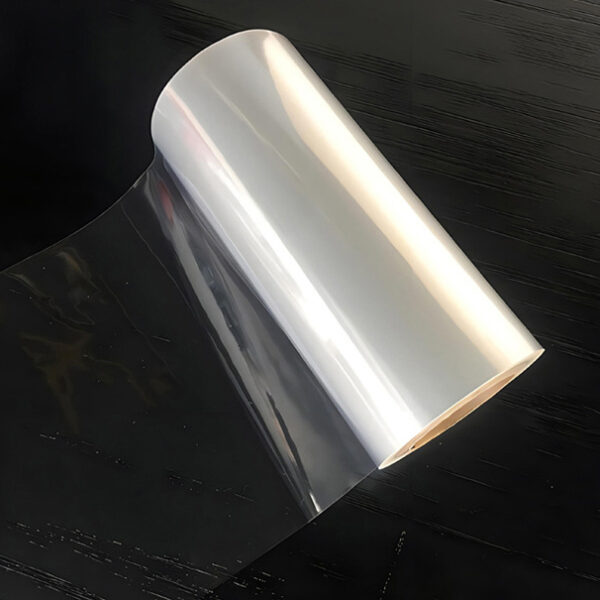

Blown vs. Cast Stretch Film

Blown stretch film is known for its high puncture resistance, making it ideal for rugged applications. In contrast, cast stretch film offers better clarity and quiet release, making it a preferred choice when transparency is needed.

Primary Uses of Stretch Film

Stretch film has an array of applications across many sectors, providing reliability and efficiency in securing various goods. Here are some key uses:

- Industrial Use: In manufacturing and logistics, stretch film stabilizes pallet loads, ensuring items remain secure throughout transport.

- Food Packaging: Food-grade stretch films are used to keep fresh produce and perishables safe from contaminants.

- Agricultural Applications: It is frequently used to protect bales of hay and silage in agricultural settings.

- Construction Sites: Stretch film wraps materials to shield them from dust, dirt, and moisture, especially on outdoor projects.

Stretch film also sees widespread use in online strapping machines and industrial shrink wrap applications, providing a cost-effective and durable way to bundle and protect large quantities of goods efficiently.

How Stretch Film Differs from Shrink Wrap

Stretch film and shrink wrap often get confused, but they serve distinct purposes:

- Stretch Film: Applied by stretching and wrapping tightly around items, requiring no heat. It’s commonly used for bundling and palletizing.

- Shrink Wrap: Applied loosely around an item, then shrunk using heat. This wrap provides a tighter fit after heat application, commonly used in retail for packaging single items.

Understanding these differences helps businesses choose the right wrapping method for specific needs.

Surprising Uses

Beyond typical packaging applications, stretch film has unique uses that showcase its versatility:

- Weatherproofing: Stretch film can cover outdoor furniture, grills, or equipment to protect them from harsh weather.

- Temporary Repairs: Used as a quick fix for broken windows or cracked items.

- Moving and Storage: Stretch film prevents scratches and keeps items intact, especially in moving or storage applications.

Stretch film provides additional benefits in unexpected ways, enhancing its value for companies looking to maximize their packaging solutions.

Industries That Rely Heavily

Several sectors utilize stretch film as a critical component of their operations:

- Manufacturing: Securing components for transport and storage.

- Retail and E-commerce: Bundling products for safe delivery.

- Agriculture: Protecting hay bales and large agricultural produce.

- Construction: Securing materials and machinery against environmental damage.

Each industry uses specific types and applications of stretch film, further highlighting its flexibility and essential role.

Choosing the Right Stretch Film

Selecting the appropriate stretch film involves considering a few key factors:

- Thickness and Strength: Heavier loads and extended storage needs may require thicker, more robust films.

- Film Type: Blown, cast, hand, or machine-applied—each type has specific benefits.

- Environmental Impact: With increasing focus on sustainability, bio-degradable and recyclable films are becoming popular choices.

For businesses needing customized solutions, such as customized labeling machines or food tray packaging machines, choosing the right film type can directly impact product protection and operational efficiency.

Common Myths

Stretch film has several misconceptions:

- Myth 1: Stretch film and cling film are the same.

- Fact: Cling film is generally used for food preservation and is thinner than industrial-grade stretch film.

- Myth 2: All stretch films perform the same.

- Fact: Different types offer varied benefits, such as puncture resistance or clarity.

- Myth 3: Stretch film is environmentally harmful.

- Fact: Bio-degradable and recycled options now offer environmentally-friendly solutions.

Clarifying these myths allows users to make informed decisions about using stretch film effectively.

Innovations and Trends

The stretch film industry has seen significant advancements in recent years:

- Eco-friendly Films: Development of recyclable and bio-degradable options.

- Enhanced Durability: UV-resistant films offer longer-lasting protection outdoors.

- Smart Packaging: Stretch films now come with trackable features for enhanced supply chain transparency.

Such trends make stretch film even more valuable, especially in sectors using industrial label printers and other high-demand equipment, where reliability and adaptability are essential.

Tips for Effective Use

Maximizing the benefits of stretch film requires proper techniques:

- Pre-stretching: Pre-stretching the film increases its cling and elasticity.

- Layering: For heavy loads, apply multiple layers to prevent shifting.

- Proper Storage: Store in a cool, dry place to preserve film quality over time.

Applying these tips ensures that stretch film performs optimally, providing effective and secure wrapping solutions.

Conclusions

Stretch film remains an indispensable asset across industries, from securing packaging machines to supporting large agricultural and manufacturing operations. With the right choice and application, stretch film enhances protection, sustainability, and operational efficiency, proving its role as a versatile and valuable tool.