Industrial packaging is a critical aspect of the global supply chain, ensuring that products are protected, organized, and prepared for safe transportation, storage, and handling. Unlike consumer packaging, which focuses on appearance and branding, industrial packaging prioritizes strength, durability, and functionality to withstand industrial environments.

Industrial packaging is a specialized packaging type designed to protect goods during transit, storage, and handling in industrial settings. Unlike consumer packaging, it prioritizes durability, functionality, and efficiency over aesthetic appeal, using materials like metal, plastic, and heavy-duty cardboard. Key categories include primary, secondary, and tertiary packaging, each serving distinct purposes for product safety and logistics.

Exploring the key aspects of industrial packaging unveils its critical role in maintaining product integrity across supply chains.

What is Industrial Packaging?

Industrial packaging is a type of packaging specifically designed to protect goods in challenging industrial environments, such as during transportation or prolonged storage. This form of packaging is essential for preventing damage, contamination, or degradation to ensure products remain intact until they reach their final destination.

Industrial packaging is packaging designed specifically for protecting goods in industrial and logistical environments, with a focus on durability over aesthetics.

In contrast to consumer packaging, which emphasizes attractive designs for retail display, industrial packaging is robust, focusing on protection, functionality, and sometimes reusability. It encompasses various materials and methods aimed at securing products for bulk handling and logistical efficiency.

Categories

Industrial packaging is categorized into three main types: primary, secondary, and tertiary packaging. Each category serves a specific role in the protection and organization of goods.

Industrial packaging categories include primary (direct contact with the product), secondary (grouping items), and tertiary (bulk handling and shipping).

- Primary Packaging: This packaging is in direct contact with the product, protecting it from contamination and damage. It often includes bags, liners, or drums, suitable for products requiring a sealed environment.

- Secondary Packaging: Used to group and contain multiple primary packages, secondary packaging provides another layer of protection and facilitates easier handling and stacking.

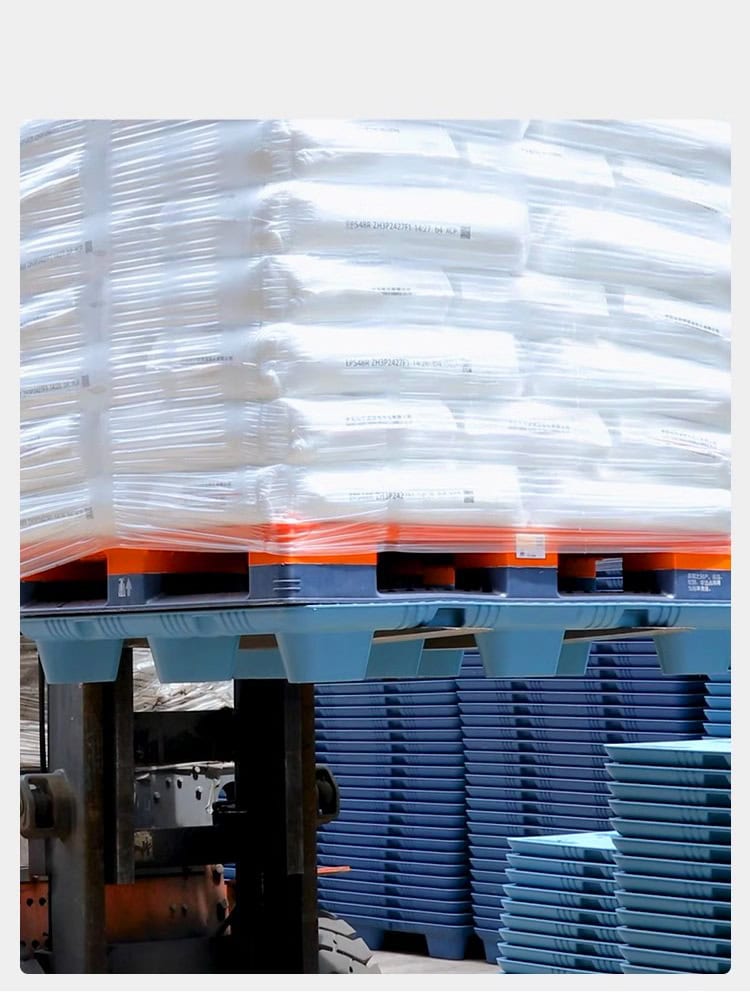

- Tertiary Packaging: This bulk packaging, such as pallets and crates, is used for mass transport and storage, ensuring safe handling across long distances.

Key Industrial Packaging Materials

The materials used in industrial packaging are selected for their durability, strength, and protective qualities, which vary based on the specific needs of the product being transported.

Common industrial packaging materials include metal, plastic, corrugated cardboard, and wood, chosen for their durability and protective qualities.

- Metal and Plastic: Metals like aluminum and steel are common for heavy-duty applications, while plastics are lightweight, flexible, and can handle various environmental conditions.

- Corrugated Cardboard and Wood: Cardboard is a cost-effective material for lighter goods, while wood is often used for crates, providing strong structural support and stability.

Types of Industrial Packaging Solutions

Industrial packaging solutions vary widely to meet different requirements, from crates and barrels to advanced options like shrink wrap and pallets. Each type is designed to secure and protect products throughout handling.

Common types include crates, barrels, pallets, and shrink wrap, each serving unique protection and transport needs.

- Crates and Pallets: These are essential for bulk handling and allow for efficient storage and stacking during transit.

- Shrink Wrap & Stretch Film: Protective films are often used to bundle products together, ensuring they remain stable and free from dust and moisture.

For sealing and stabilizing products during transportation, many companies also rely on the efficiency of a Shrink wrap Machine for securing pallets and products, reducing the risk of damage.

Processes and Methods

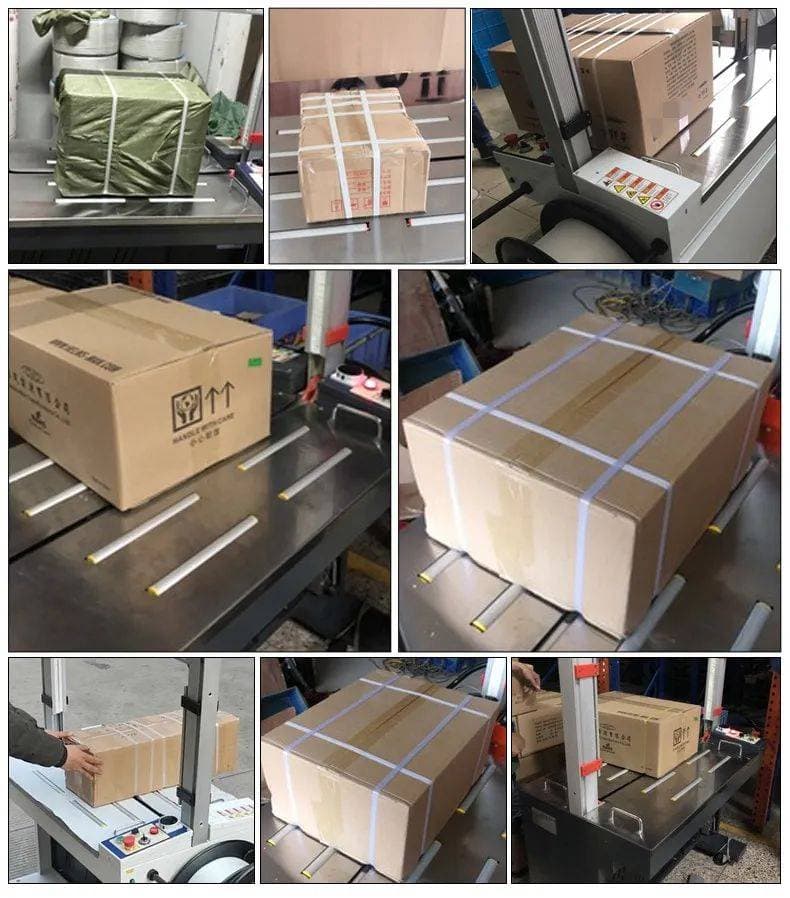

Industrial packaging involves various processes, including sealing, wrapping, and labeling. These steps are necessary for securing products and providing handling instructions for logistics staff.

Methods like sealing, shrink wrapping, and labeling are essential for securing products and ensuring proper handling in transit.

- Sealing and Wrapping: These processes protect goods from moisture, dust, and other environmental factors that could lead to degradation.

- Labeling: Using equipment like an industrial label printer ensures that packages are marked with essential handling information, regulatory compliance notes, and destination details for streamlined logistics.

Differences Between Industrial and Consumer Packaging

Although both consumer and industrial packaging serve to contain and protect products, their purposes and approaches differ significantly.

Unlike consumer packaging, industrial packaging prioritizes durability and protection for transit, often using bulkier materials.

- Focus on Functionality: Consumer packaging is designed for retail shelves, appealing to customers with design and branding. Industrial packaging emphasizes strength and utility, ensuring products withstand the physical demands of transit.

- Aesthetic vs. Durability: While consumer packaging may prioritize brand representation, industrial packaging is heavier and often less visually appealing, focused on practical needs rather than appearance.

The Importance in Supply Chains

Industrial packaging is vital to maintaining product quality and ensuring efficient logistics, directly impacting the success of supply chains.

Industrial packaging plays a critical role in ensuring product safety, reducing damage, and streamlining logistics in supply chains.

- Protection in Transit: Industrial packaging prevents products from breaking, leaking, or degrading, preserving their quality until they reach the end user.

- Logistics Efficiency: By using durable materials and secure designs, industrial packaging enhances handling and storage efficiency, saving time and costs in the supply chain.

Industrial Packaging Job Roles and Responsibilities

Roles in the industrial packaging sector include packaging engineers and specialists responsible for selecting materials, designing packages, and ensuring compliance with industry standards.

Industrial packaging roles include packaging engineers and specialists focused on material selection, design, and compliance.

- Packaging Engineers: These professionals design packaging solutions that meet product requirements, often collaborating with product managers and logistics teams.

- Inspectors and Quality Control: Packaging inspectors are responsible for quality checks, ensuring that packaging meets regulatory standards and provides adequate protection.

Trends and Innovations

As environmental awareness grows, so does the demand for sustainable and efficient packaging solutions. Key trends in the industry include sustainability, automation, and customization.

Sustainability, automation, and customization are major trends shaping the future of industrial packaging.

- Eco-Friendly Packaging: Many companies are shifting to recyclable or biodegradable materials, reducing environmental impact while maintaining product protection.

- Automation: Advanced machines like the Filling Machine streamline the packaging process, enabling faster, more precise filling and sealing for various goods.

Leading Industrial Packaging Companies

Some of the largest companies in industrial packaging include International Paper, Smurfit Kappa, and Berry Global, known for innovative and durable packaging solutions.

Top companies like International Paper, Smurfit Kappa, and Berry Global lead in providing innovative industrial packaging solutions.

- Market Leaders: These companies provide a wide range of packaging solutions, from heavy-duty crates to eco-friendly materials, tailored to meet industry needs.

- Unique Offerings: Many market leaders focus on creating sustainable, customized packaging options that cater to the evolving demands of global logistics.

Conclusion

Industrial packaging is essential in protecting, storing, and transporting goods across various industries. By choosing the right materials and designs, businesses ensure product integrity and streamline supply chain operations.