Packaging lines in modern industries often require continuous, reliable strapping to secure packages efficiently. Without an automated system, companies face bottlenecks, increased labor costs, and package instability. Online strapping machines offer a streamlined, automated solution that ensures consistent, high-speed strapping, supporting optimal productivity in demanding settings.

Online strapping machines are automated systems that continuously strap packages along production lines. They provide secure, consistent strapping, reduce labor costs, and improve packaging efficiency, making them indispensable for high-demand industries.

Explore how online strapping machines work, their benefits, and the critical role they play in modern production lines.

What is an Online Strapping Machine?

An online strapping machine is a fully automated device designed to secure packages or bundles with strapping material as they move along a production line. Unlike manual or semi-automatic strapping machines, online models operate seamlessly within automated workflows, providing consistent, high-speed strapping without manual intervention. Online strapping machines are essential in various industries where continuous, large-volume packaging is required.

These machines are tailored for high-demand environments and can operate independently or be integrated with other packaging systems, such as packaging machines or labeling machines, to form a cohesive packaging line.

Types of Strapping Machines and Their Applications

Strapping machines are categorized into three main types:

- Manual Strapping Machines – Operated entirely by hand, these are suited for low-volume or specialty applications.

- Semi-Automatic Strapping Machines – Require some manual effort but automate parts of the process, ideal for medium-volume operations.

- Online (Fully Automatic) Strapping Machines – Integrate directly into production lines and provide continuous strapping for high-volume packaging needs.

Online strapping machines are particularly popular in industries such as logistics, warehousing, and manufacturing, where high-speed packaging and consistent strapping are essential. They support efficiency in e-commerce, automotive, and liquid filling machine applications.

Benefits of Using an Online Strapping Machine

1. Enhanced Efficiency

By automating the strapping process, online strapping machines significantly increase the speed of packaging. This reduces downtime and enables high-volume throughput, freeing workers to focus on other critical tasks.

2. Improved Consistency

Online strapping machines apply uniform tension and seal strapping securely, ensuring that every package meets the same standard of stability and safety. This consistency reduces the likelihood of damaged or unsecured packages.

3. Cost Savings

Reduced labor requirements lead to lower operating costs, as fewer staff members are needed to oversee or manually strap packages. Additionally, fewer strapping errors mean less material waste and improved overall efficiency.

4. Increased Safety

Automated strapping machines reduce the risk of repetitive strain injuries associated with manual strapping. They also prevent potential accidents by maintaining safe, controlled strapping environments.

How Online Strapping Machines Work

The operation of an online strapping machine follows a straightforward process:

- Loading: Packages are placed onto a conveyor belt that feeds them into the strapping machine.

- Detection and Positioning: Sensors detect the package’s arrival, positioning it for precise strapping.

- Strapping Cycle: The machine automatically wraps the package with a pre-determined length of strapping, applies tension to secure it, seals the strap, and then cuts it.

- Ejection: The strapped package is ejected from the machine and continues along the conveyor for further processing.

Online strapping machines are compatible with various strapping materials, including polypropylene, polyester, and steel, each offering different levels of durability and strength.

Different Strapping Materials and Their Uses

Selecting the right strapping material is essential for ensuring package integrity:

- Polypropylene (PP): Lightweight and economical, PP strapping is suitable for light-duty applications.

- Polyester (PET): Known for its strength and durability, PET strapping is ideal for medium to heavy-duty applications.

- Steel: This is the strongest type, used for securing heavy-duty shipments and industrial materials.

Each material offers unique benefits, so companies often choose based on the package weight, handling conditions, and storage or shipping requirements.

Common Industries Utilizing Online Strapping Machines

Online strapping machines are versatile and widely used across various sectors, including:

- Logistics and Distribution Centers: They ensure secure, efficient packaging for high-volume shipments.

- E-commerce Fulfillment: Strapping provides tamper-proof security, ideal for protecting goods during transit.

- Manufacturing: Particularly useful in automotive, electronics, and food processing industries, where bundling and stability are critical.

These industries rely on online strapping machines to maintain continuous production flow, reduce bottlenecks, and ensure packaging reliability.

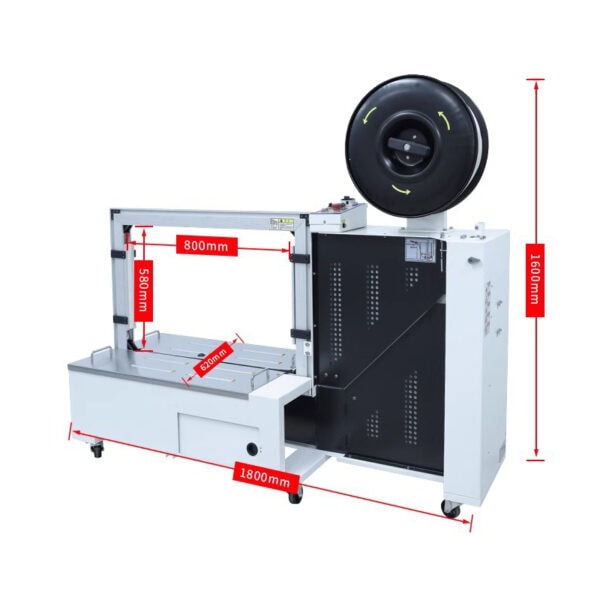

Features to Look for in an Online Strapping Machine

When choosing an online strapping machine, consider the following features:

- Speed: A machine’s strapping speed (cycles per minute) should align with production line needs.

- Durability and Compatibility: Machines should be compatible with various strapping materials and withstand high-frequency use.

- Adjustable Tension and Settings: Machines with customizable settings can handle a variety of package sizes and types.

- User Interface: A user-friendly interface simplifies operation and ensures seamless integration with existing systems, like automated packaging lines.

Maintenance and Troubleshooting of Strapping Machines

To keep an online strapping machine operating optimally, regular maintenance is essential:

- Daily Checks: Inspect for wear on components like the sealing head, tensioning mechanism, and rollers.

- Sensor Calibration: Sensors must be calibrated to ensure accurate package detection.

- Common Troubleshooting: For issues like strap misfeeds, tension errors, or sensor malfunctions, consult the machine’s manual or seek professional support.

Routine maintenance prolongs the machine’s lifespan, minimizes downtime, and ensures consistent performance.

Cost Considerations and ROI for Businesses

While the initial investment in an online strapping machine may be substantial, the ROI is significant for high-demand operations. The benefits include reduced labor costs, fewer errors, and increased production speeds. Case studies in logistics and manufacturing demonstrate substantial savings and improved efficiency, highlighting the machine’s value for businesses of all sizes.

Frequently Asked Questions about Online Strapping Machines

- What package sizes can online strapping machines handle?

Most machines can be adjusted to strap packages of various sizes, though this depends on the machine’s specifications.

- How does automatic strapping compare to manual strapping in terms of cost?

Automatic strapping reduces labor costs and packaging errors, making it more cost-effective over time.

- Are online strapping machines suitable for delicate items?

Yes, most machines offer adjustable tension settings, allowing for secure yet gentle strapping.

Conclusions

Online strapping machines enhance packaging efficiency and reduce operational costs, making them a vital asset in industries with high packaging demands.