Unsealed containers can lead to product leakage, contamination, and reduced shelf life, harming both consumer trust and business profitability. This can cause reputational damage and expensive recalls for businesses. An induction sealing machine provides a reliable solution to ensure leak-proof, tamper-evident seals that maintain product integrity.

An induction sealing machine is a device that uses electromagnetic induction to seal containers with foil liners, creating airtight seals that preserve freshness, prevent leaks, and ensure tamper evidence.

Let’s explore how these machines work, their benefits, and their essential role in modern packaging solutions.

How Does an Induction Sealing Machine Work?

Induction sealing machines operate on the principle of electromagnetic induction. They use an induction coil to generate a high-frequency electromagnetic field, which heats a foil liner embedded in a cap or sealing wad. The heat activates an adhesive layer on the liner, bonding it to the container opening.

Key Steps in the Process:

- A cap containing a foil liner is placed on a container.

- The container passes under the induction coil, which generates heat.

- The adhesive on the foil melts, bonding the liner to the container’s rim.

This process ensures a hermetic seal without direct contact between the machine and the container.

What Are the Main Applications of Induction Sealing Machines?

Induction sealing machines are widely used in industries like food and beverage, pharmaceuticals, cosmetics, and chemicals. These machines are particularly effective for creating tamper-evident seals and preserving product freshness.

Common Use Cases:

- Sealing bottles of juice, milk, and other beverages.

- Tamper-proof sealing of pharmaceutical products.

- Preserving the integrity of chemical containers.

Induction sealing machines work seamlessly with bottle labeling machines and capping machines, providing comprehensive solutions for industrial packaging lines.

Benefits of Using Induction Sealing Machines

The benefits of induction sealing are manifold, making them indispensable in industrial applications.

Advantages Include:

- Leak Prevention: Prevents product leakage during transportation and storage.

- Extended Shelf Life: Airtight seals protect products from external contaminants.

- Tamper Evidence: Provides consumers with visual assurance of product integrity.

Additionally, induction sealing is energy-efficient and compatible with high-speed production lines.

Difference Between Induction Sealing and Conduction Sealing

While both processes involve heat application, there are key differences:

- Induction Sealing: Non-contact process using electromagnetic induction. Suitable for sealing containers made of a variety of materials.

- Conduction Sealing: Requires direct contact between the heat source and the sealing surface, often slower and less versatile.

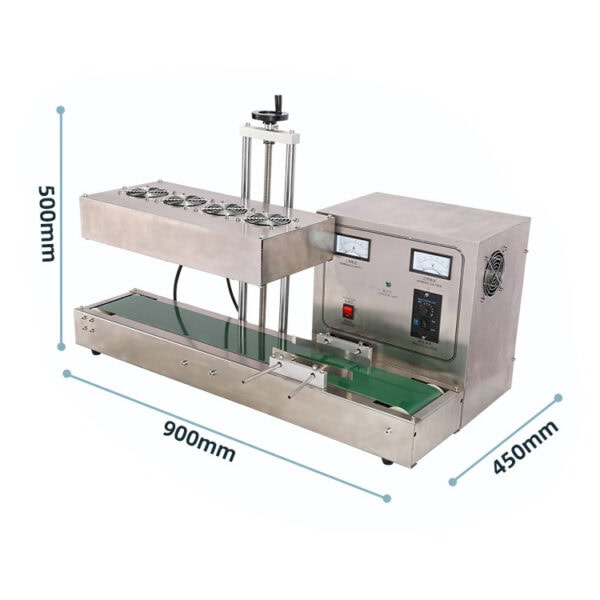

Types of Induction Sealing Machines

Induction sealing machines come in several variations, depending on the scale and requirements of production lines.

Categories:

- Manual Sealers: Ideal for small-scale operations or testing.

- Semi-Automatic Machines: Suitable for mid-sized businesses needing a balance of speed and cost-efficiency.

- Fully Automatic Machines: Designed for large-scale industrial production.

Cost Factors of Induction Sealing Machines

The cost of an induction sealing machine depends on its features, automation level, and capacity. For businesses already utilizing industrial label printers and bottle filling machines, these machines are a natural addition to the production line.

Key Considerations:

- Production volume.

- Energy efficiency.

- Maintenance requirements.

Common Problems and Troubleshooting

Induction sealing machines are reliable, but issues may arise during operation.

Typical Challenges:

- Incomplete Seals: Adjust sealing time or liner material.

- Material Incompatibility: Ensure container and liner compatibility.

- Overheating: Regularly check the cooling system.

Comparison: Induction Seal vs Heat Seal

Induction sealing and heat sealing are often compared in packaging.

- Induction Seal: Faster, non-contact, suitable for diverse materials.

- Heat Seal: Requires contact, better for certain high-temperature applications.

How to Select the Right Induction Sealing Machine?

Selecting the right induction sealing machine involves assessing production requirements and compatibility with other equipment, such as customized labeling machines and taping machines.

Key Factors:

- Production speed and container material.

- Compatibility with existing systems.

- Budget and scalability for future needs.

Future Trends in Induction Sealing Technology

As packaging technology evolves, induction sealing machines are becoming smarter and more efficient.

Emerging Trends:

- IoT Integration: Smart sensors to monitor performance and maintenance.

- Eco-Friendly Materials: Compatibility with recyclable and biodegradable liners.

- Automation: Enhanced automation for high-speed, low-error operations.

Conclusion

An induction sealing machine is essential for ensuring product safety, freshness, and tamper-evidence in a variety of industries. By combining these machines with other advanced packaging solutions like automatic liquid packaging machines, businesses can streamline their production lines and maintain the highest standards of quality.