Manual labeling challenges such as inconsistency and inefficiency can hinder production growth and inflate costs. Automatic labeling machines offer a streamlined, precise solution to labeling needs, enhancing productivity and reducing human intervention.

What is an Automatic Labeling Machine?

An automatic labeling machine is a device that applies labels to products with precision and efficiency. It automates the labeling process, ensuring consistency, accuracy, and speed across various industries.

Explore their components, uses, and benefits to understand how they redefine modern manufacturing processes.

Definition and Purpose of Automatic Labeling Machines

Automatic labeling machines automate the process of affixing labels to products, eliminating the need for manual labor. These machines ensure high accuracy, making them essential for industries requiring precise product identification.

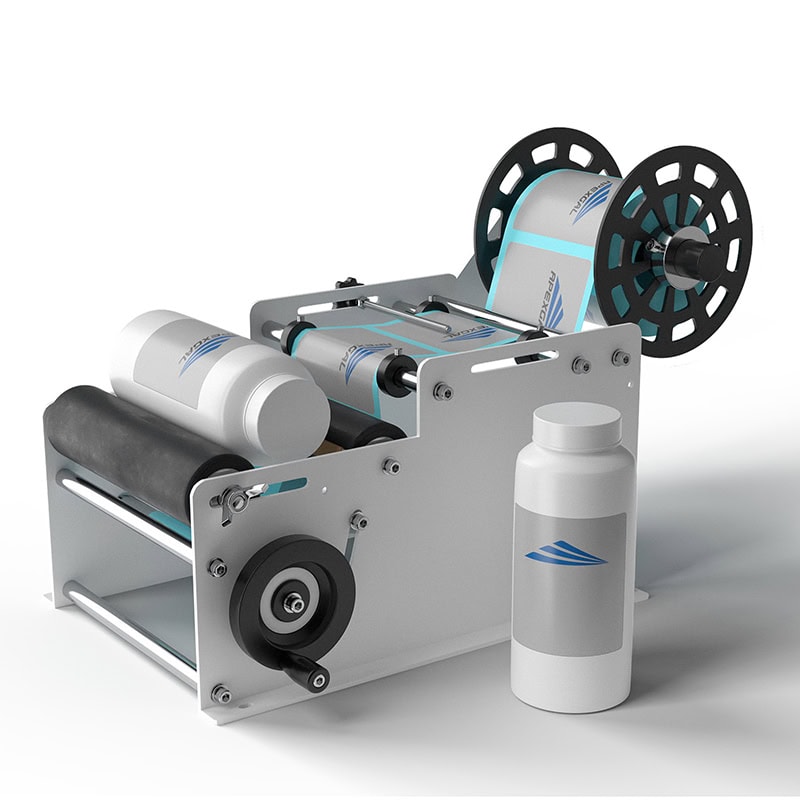

For instance, a rolling bottle labeling machine can label up to 1,500 products per hour, reducing time and labor costs compared to manual methods.

Types of Automatic Labeling Machines

By Automation Level:

- Semi-Automatic Labeling Machines: Operators place products for labeling; ideal for smaller-scale operations.

- Fully Automatic Labeling Machines: Entirely autonomous and integrated into production lines for maximum efficiency.

By Product Type:

- Bottle Labeling Machines: Designed for cylindrical and curved surfaces.

- Flat Labeling Machines: Perfect for labeling flat or rectangular products.

- Flag Labeling Machines: Specialized for cables, wires, and irregular shapes.

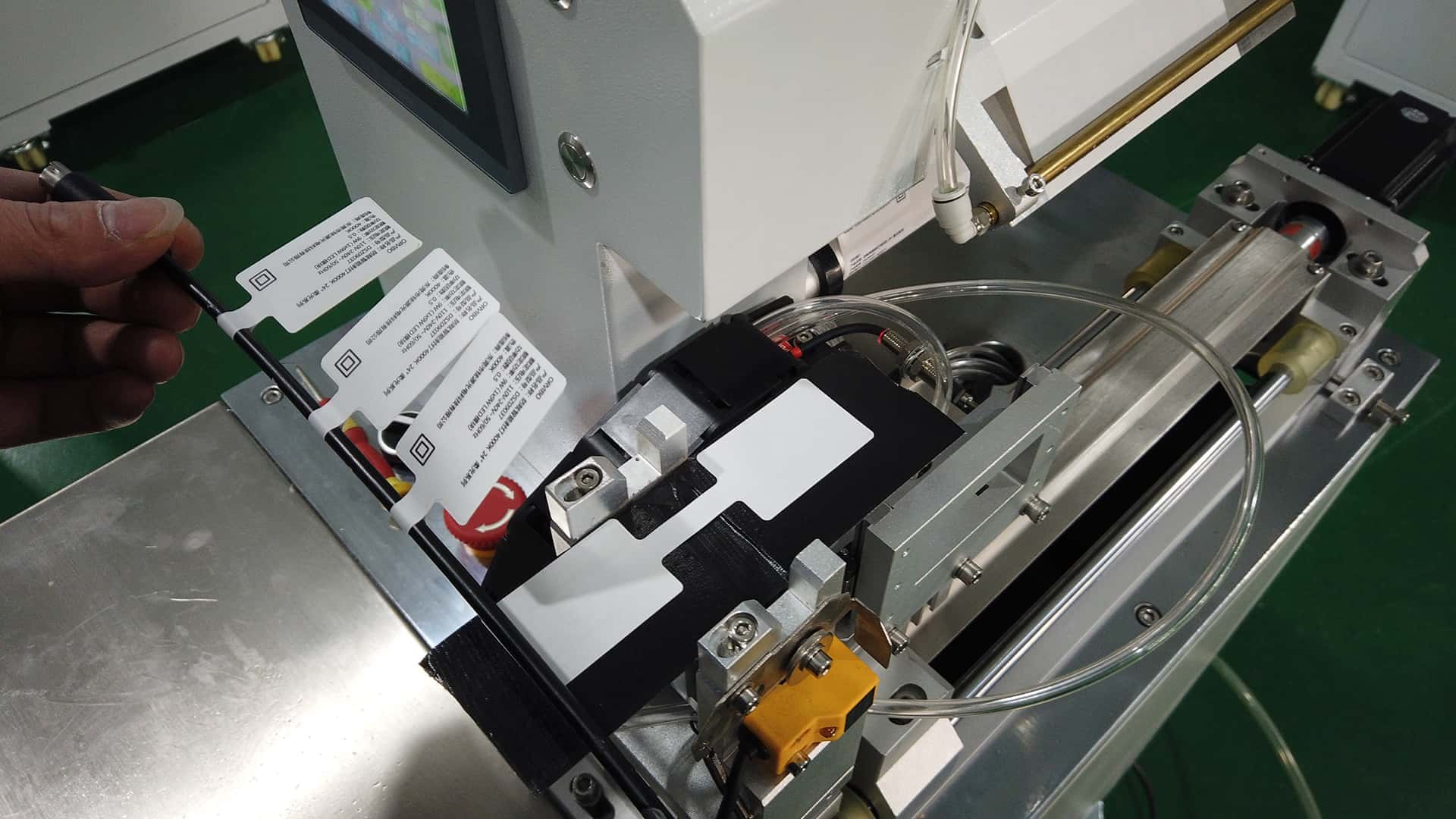

Core Components and Mechanisms

Key Components:

- Label Applicators: Peel and apply labels to surfaces.

- Sensors: Detect product presence and manage label placement.

- PLC System: Controls timing and coordination for seamless operation.

- Conveyors and Rollers: Transport products smoothly during the labeling process.

Mechanisms:

Sensors signal the PLC system, initiating label peeling and application. Precision adjustments ensure the label aligns accurately, even for products with unique shapes or sizes.

Working Principle

Automatic labeling machines function through synchronized operations:

- Detection: Sensors identify incoming products.

- Peeling: Labels are prepared for application.

- Application: Labels adhere to products as they pass through the machine.

- Verification: Quality checks ensure proper placement.

For example, a positioning bottle labeling machine can handle multiple label positions within one cycle, ensuring precise alignment for each product.

Applications Across Industries

Automatic labeling machines are versatile and cater to diverse sectors:

- Food and Beverage: Labeling bottles, jars, and packaging.

- Pharmaceuticals: Accurate labeling for medicine bottles and packages.

- Electronics: Barcodes and safety labels for components.

- Cosmetics: Brand labeling for bottles and containers.

Benefits of Automatic Labeling Machines

Efficiency and Accuracy:

Automatic machines significantly boost productivity while maintaining consistent labeling accuracy, often within ±0.5mm.

Cost Reduction:

They lower operational costs by minimizing the need for manual labor, especially in high-output production environments like liquid filling machine workflows.

Customizable Features

- Adjustable Label Sizes: Accommodates various product dimensions.

- Speed Settings: Matches labeling pace with production demands.

- Material Compatibility: Handles paper, plastic, or eco-friendly label materials.

For unique needs, customized labeling machines can be tailored to specific product shapes, sizes, and labeling styles.

Challenges and Troubleshooting

Common Issues:

- Misaligned labels or label jams.

- Sensor miscalibration causing inaccurate application.

Solutions:

Regular maintenance, operator training, and precise setup adjustments are crucial to resolving these challenges.

Integration with Other Systems

Automatic labeling machines often integrate with complementary equipment:

- Filling Machines: Labeling bottles after liquid or powder filling.

- Shrink Wrap Machines: Securing labeled products with protective wrapping.

- Capping Machines: Adding caps to labeled containers for a complete process.

Future Trends in Labeling Technology

- AI Integration: Adaptive systems for real-time adjustments.

- Eco-Friendly Labeling: Increased use of sustainable materials.

- Enhanced Connectivity: Linking machines with cloud-based monitoring systems.

Conclusion

Automatic labeling machines are vital for industries aiming for efficiency, accuracy, and cost reduction. From bottle labeling machines to flag labeling machines, these versatile tools ensure high-quality results and smooth production processes. Investing in the right labeling solution is a strategic move to enhance operational efficiency and product appeal.