Many pharmaceutical companies struggle with slow, inconsistent capsule production, risking revenue and client satisfaction. Capsule fillers offer a fast, reliable solution to improve efficiency.

A capsule filler is a machine used to fill empty capsules with substances like powders, granules, or liquids, essential in pharmaceuticals, nutraceuticals, and cosmetics. It improves production efficiency and consistency.

Understanding capsule fillers’ operation and benefits helps industries maximize efficiency while maintaining product quality.

What is a Capsule Filler?

A capsule filler is a specialized machine designed to fill empty capsules with various substances, including powders, granules, or liquids. Widely used in the pharmaceutical, nutraceutical, and cosmetics industries, these machines streamline production by enhancing efficiency and consistency. They come in different configurations to cater to varied production scales, ensuring precise dosing and quality in every capsule.

Capsule fillers are integral in manufacturing medications, dietary supplements, and even certain cosmetic products. Their ability to accommodate various capsule sizes and formulations makes them highly versatile and indispensable in modern manufacturing.

How Does a Capsule Filling Machine Work?

The operation of a capsule filling machine is both systematic and efficient. First, empty capsules are sorted and oriented into the machine’s capsule hopper. Next, the machine separates the capsules into two parts—the body and the cap. The body is filled with the desired material using a tamping pin, piston, or dosator system.

Once filled, the cap is replaced, and the capsule is securely sealed. Finally, the machine ejects the filled capsules, ready for packaging or further processing. This workflow ensures uniformity and minimizes human error, making capsule fillers ideal for mass production.

Types of Capsule Filling Machines

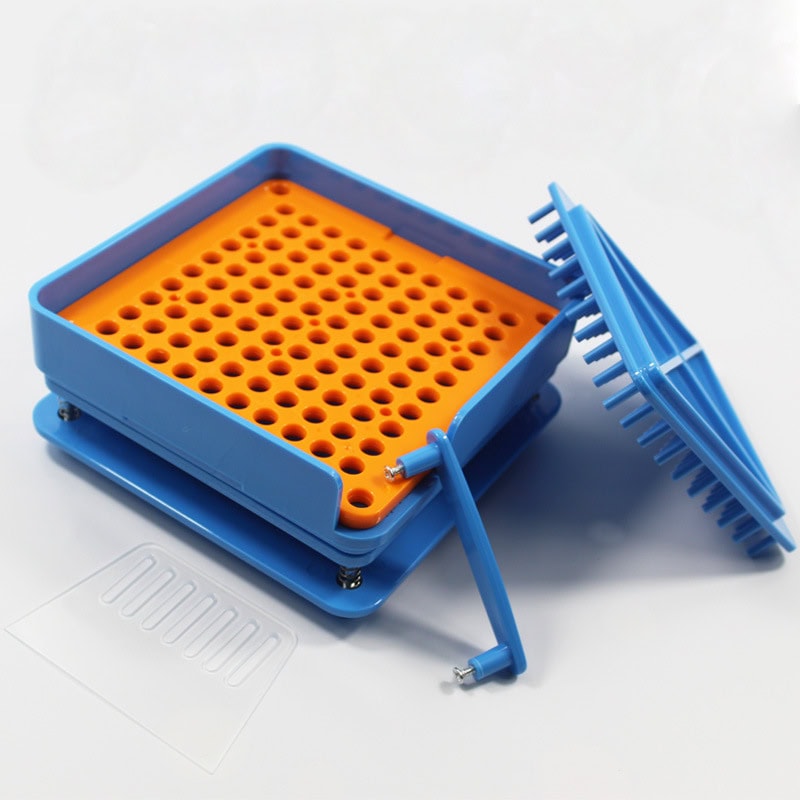

Manual Capsule Filling Machines

These machines are best suited for small-scale operations. They are cost-effective, portable, and easy to use, making them a popular choice for startups and small manufacturers.

Semi-Automatic Capsule Filling Machines

Semi-automatic machines combine manual and automated processes. Operators handle capsule loading and unloading, while the machine automates filling. These machines are ideal for mid-sized operations requiring moderate production volumes.

Fully Automatic Capsule Filling Machines

Designed for high-speed, large-scale production, fully automatic machines handle all steps—from capsule orientation to sealing—with minimal human intervention. These are commonly used in pharmaceutical and nutraceutical industries.

Advantages of Capsule Fillers

Using a capsule filler offers numerous benefits:

- Efficiency and Consistency: Automating the filling process reduces errors and ensures uniform capsule weight.

- Cost-Effectiveness: By minimizing manual labor, capsule fillers lower operational costs over time.

- Regulatory Compliance: Machines are designed to meet industry standards, ensuring hygienic and contamination-free production.

The Principle of Capsule Filling

Capsule fillers operate on several core principles:

- Tamping: Compressing the material into the capsule body for a uniform fill.

- Dosator: A mechanism that directly transfers the pre-measured dose into the capsule.

- Piston Filling: A system used for precise filling of liquids and semi-liquids.

Each method ensures consistent results, tailored to the type of material being used.

Applications of Capsule Filling Machines

Capsule fillers have a broad range of applications:

- Pharmaceuticals: Precisely measured doses for medications.

- Nutraceuticals: Production of dietary supplements and vitamins.

- Cosmetics: Encapsulation of powders and oils for skincare products.

What are the Benefits of Liquid-Filled Capsules?

Liquid-filled capsules offer distinct advantages:

- Enhanced Bioavailability: Liquids are more readily absorbed by the body.

- Improved Stability: Encapsulation protects sensitive ingredients from degradation.

- Taste Masking: Encapsulation eliminates unpleasant flavors, improving consumer acceptance.

Key Factors to Consider When Choosing a Capsule Filler

Selecting the right capsule filler depends on various factors:

- Production Scale: Manual for small batches, semi-automatic for medium volumes, and fully automatic for large-scale production.

- Material Properties: Compatibility with powders, granules, or liquids.

- Capsule Sizes: Machines must accommodate the required capsule sizes for production.

Maintenance and Troubleshooting

To ensure long-lasting performance:

- Regularly clean and lubricate the machine.

- Address common issues, such as capsule misalignment or irregular fills, promptly.

- Partner with a reliable manufacturer for technical support.

Capsule Filling Machine Safety and Compliance

Adhering to GMP (Good Manufacturing Practices) and FDA guidelines is crucial. Capsule fillers are designed to meet these standards, ensuring safe and contamination-free production environments.

Conclusion

Capsule fillers revolutionize production processes in pharmaceuticals and other industries, enhancing speed, efficiency, and accuracy while meeting stringent quality standards.

For those considering integrating capsule filling machines, they pair well with complementary equipment like the bottle labeling machine and powder filling machine to create a streamlined production line.