One of the problems with putting on labels manually and doing it inconsistently is you screw it up, you’re inefficient, and you waste resources. Bottle sticker labeling machines solve that problem because they automate the process, make it accurate, and make you more efficient.

Benefits of bottle sticker labeling machines are improved labeling accuracy, faster production, reduced manual labor, improved brand presentation, lower operating costs, and the ability to label different sizes and shapes of products.

Keep reading to find out the top benefits of using a bottle sticker labeling machine in your production line.

Enhanced Labeling Accuracy

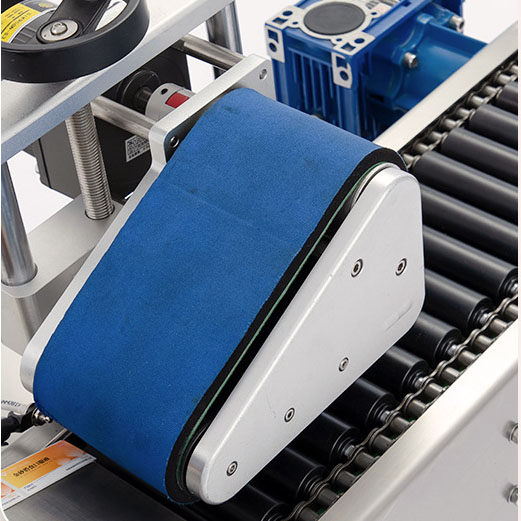

Bottle sticker labeling machines provide precise label placement, eliminating errors common with manual application. These machines use sensors and advanced mechanisms to ensure that labels are applied uniformly, improving the overall product presentation.

With accuracy levels as precise as ±0.5mm, companies can maintain consistent product labeling, essential for brand integrity and regulatory compliance.

Increased Production Speed

Automation allows these machines to label hundreds or even thousands of bottles per hour, significantly boosting production rates. This is particularly beneficial for large-scale manufacturers who need to meet high demand without sacrificing quality.

The machine’s ability to continuously apply labels without interruption reduces bottlenecks in production, leading to greater operational efficiency.

Cost Savings

Investing in a bottle sticker labeling machine reduces the need for manual labor, cutting operational costs. Fewer errors in label application also mean less waste of labels and products, resulting in additional cost savings over time.

Moreover, the machine’s durability ensures long-term use with minimal maintenance, further contributing to lower costs.

Versatility in Labeling

These machines are highly adaptable, capable of handling a variety of bottle shapes, sizes, and materials. From round to square bottles, glass to plastic, they can adjust to different labeling needs with minimal reconfiguration.

This flexibility makes them an ideal solution for companies that produce multiple product lines or frequently change labeling requirements.

Enhanced Branding and Aesthetics

Well-applied labels enhance the overall look of a product, making it more appealing to consumers. Bottle sticker labeling machines ensure that labels are applied smoothly and without bubbles or creases, helping to maintain a professional brand image.

A neat and consistent label application also improves shelf appeal, which can boost sales.

Ease of Operation and Maintenance

Modern bottle sticker labeling machines are designed with user-friendly interfaces, making them easy to operate even for staff with minimal technical expertise. Most machines offer touch-screen controls and automated settings that streamline the labeling process.

Additionally, these machines are built with durability in mind, requiring minimal maintenance while maintaining high operational efficiency.

Compatibility with Different Label Types

Bottle labeling machines can handle various types of labels, including self-adhesive, barcode, and custom-printed labels. This versatility makes it easier for companies to switch between different labeling formats, depending on their specific needs.

This feature is especially useful for businesses that need to comply with different labeling regulations across markets.

Compliance with Industry Regulations

In industries like food and pharmaceuticals, proper labeling is crucial for compliance with legal requirements. Bottle sticker labeling machines ensure that labels are placed accurately, reducing the risk of non-compliance due to mislabeling.

This capability helps businesses avoid costly penalties or product recalls.

Improved Worker Safety

Automating the labeling process reduces the physical strain on workers, lowering the risk of repetitive strain injuries. Workers are no longer required to manually apply labels, which can be a time-consuming and physically demanding task.

Additionally, fewer human errors occur, leading to a safer work environment.

Scalability for Business Growth

As businesses grow and production volumes increase, bottle sticker labeling machines can easily scale to meet higher output demands. This scalability ensures that companies can keep up with increasing market demand without significant additional investment in equipment.

Many machines can be integrated into existing production lines, allowing businesses to expand their operations seamlessly.

Conclusion

Bottle sticker labeling machines offer multiple benefits, from increased efficiency and cost savings to improved brand presentation and regulatory compliance, making them essential for modern production lines.

You may be interested in: