Struggling with product spoilage, packaging inefficiency, and increased waste can hinder your business’s growth and profitability. Without a proper sealing solution, these issues often escalate, leading to dissatisfied customers and operational losses. The answer? Sealing machines – versatile tools that preserve quality, reduce costs, and streamline packaging processes.

Sealing machines enhance preservation, improve efficiency, minimize waste, ensure safety, elevate aesthetics, and support sustainability. They are indispensable tools across industries, offering unmatched versatility, durability, and cost savings.

Let’s explore how sealing machines add value to your business operations and product packaging.

How Do Sealing Machines Improve Product Preservation?

Sealing machines play a critical role in safeguarding product quality by creating airtight seals that prevent contamination and spoilage. These machines are essential for preserving the freshness of food, beverages, and other perishable goods.

Sealing machines extend shelf life by minimizing exposure to oxygen, moisture, and contaminants, ensuring that products maintain their original taste, texture, and safety.

Improved Airtightness

A sealing machine creates a robust barrier that eliminates the risk of spoilage by preventing the ingress of air and moisture. For instance, when paired with a liquid packaging machine, it ensures liquids remain uncontaminated and fresh over extended periods.

Preservation of Freshness

Sealing machines are widely used in the food industry to maintain the flavor, texture, and aroma of consumable goods. Their effectiveness has made them indispensable for vacuum-sealed packaging and ready-to-eat products.

What Role Do Sealing Machines Play in Operational Efficiency?

Sealing machines significantly enhance productivity by automating and accelerating the packaging process. This efficiency leads to faster production cycles and reduced labor costs.

By integrating automated systems, sealing machines streamline operations, optimize manpower, and reduce the time spent on repetitive tasks.

Automation in Action

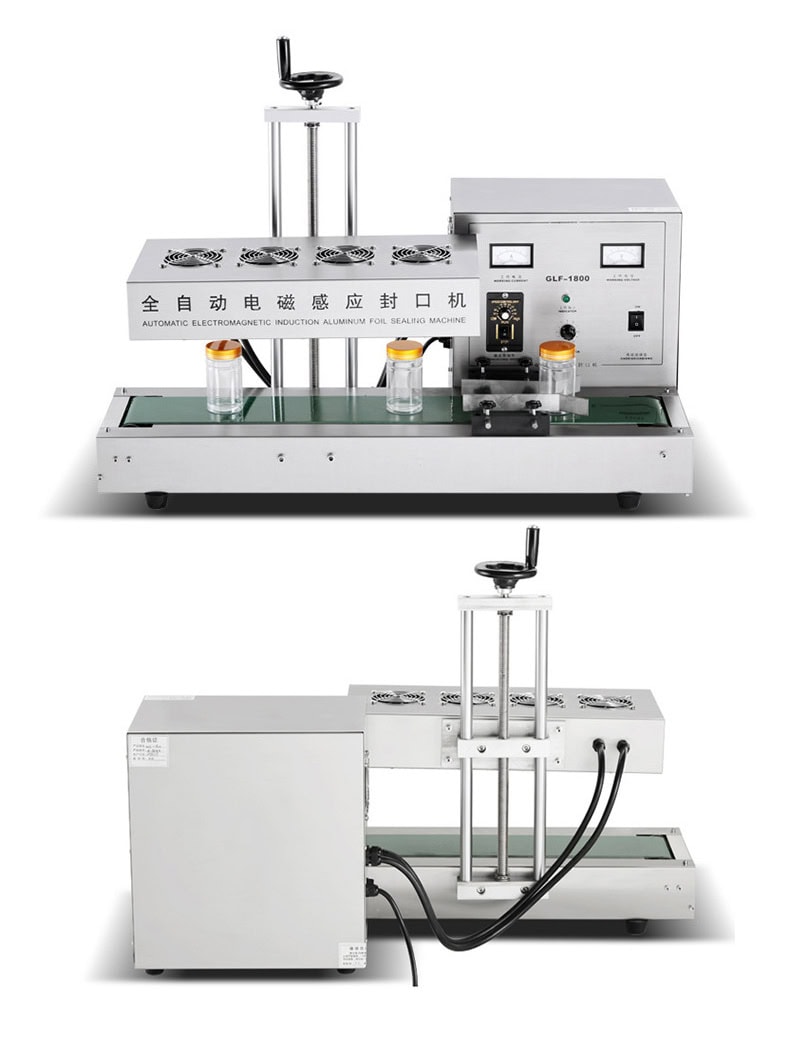

Modern sealing machines can be incorporated into automated production lines, such as those using flat labeling machines, ensuring a seamless workflow from labeling to sealing. This integration eliminates bottlenecks and minimizes errors.

Enhanced Speed

Compared to manual sealing, automatic machines can seal hundreds of products per hour, offering unparalleled speed and consistency. Such productivity is crucial for businesses scaling up operations.

How Do Sealing Machines Minimize Material Wastage?

Using sealing machines ensures that packaging materials are used more efficiently, reducing overall waste and promoting sustainability. Precise sealing mechanisms eliminate the need for additional packaging adjustments or repairs.

Sealing machines are designed to optimize material use, reducing waste and ensuring clean, uniform packaging that aligns with environmental goals.

Efficient Material Usage

Advanced sealing machines employ precision technology to ensure accurate sealing without excess material usage. When paired with industrial shrink wrap, this feature enhances cost savings.

Cost-Saving Examples

For example, companies using sealing machines for powder or liquid products often report reduced material costs as the machines deliver exact, spill-free seals every time.

Why Are Sealing Machines Important for Product Safety?

Sealing machines create tamper-evident seals that ensure product integrity and meet industry safety standards. These features are critical for sectors like food, pharmaceuticals, and chemicals.

By providing tamper-proof packaging, sealing machines protect against contamination, unauthorized access, and ensure compliance with safety regulations.

Tamper-Evident Seals

The use of tamper-evident seals reassures customers about the safety and authenticity of products. For example, combining sealing machines with capsule filling machines guarantees pharmaceutical products are secure and intact.

Compliance with Laws

Sealing machines help businesses meet stringent packaging standards, minimizing the risk of recalls and legal issues. They are essential for industries with strict safety requirements.

Conclusion

Sealing machines are more than packaging tools; they are essential for ensuring quality, safety, and operational efficiency. With their ability to preserve products, reduce waste, and streamline workflows, these machines offer immense value to businesses across diverse industries.