A self adhesive label machine offers numerous advantages, from boosting production efficiency to enhancing the overall presentation of your products. Whether you’re looking to reduce costs, improve accuracy, or increase the versatility of your labeling operations, this type of machine is a worthwhile investment.

As someone who has spent over two decades in the automation equipment industry, I’ve seen firsthand the transformative impact that these machines can have on production lines.

Understanding Self Adhesive Label Machines

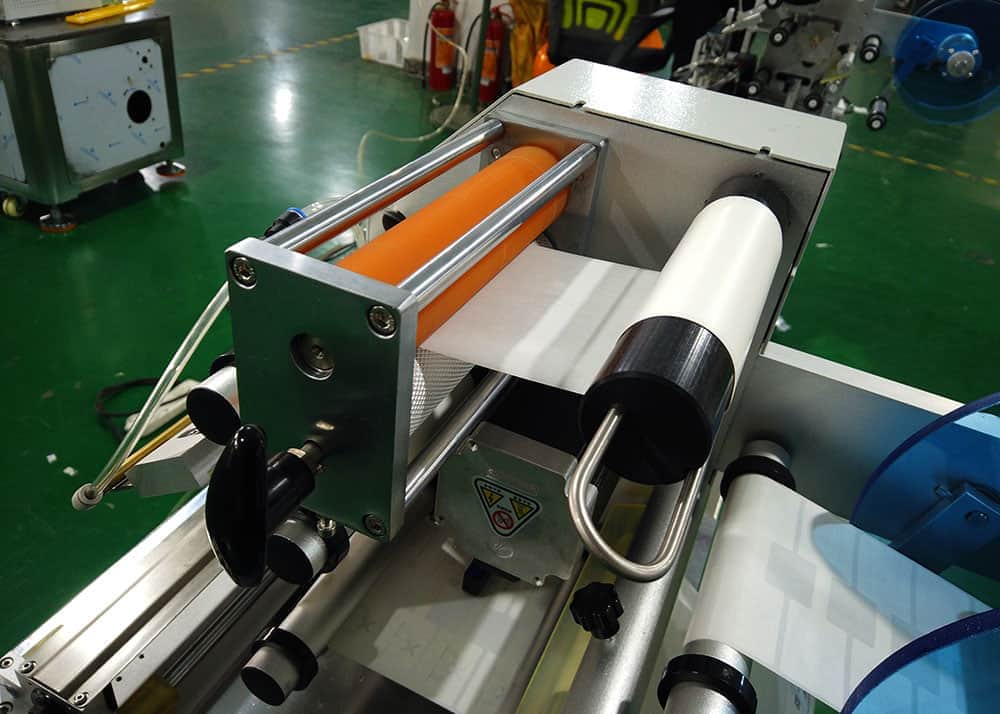

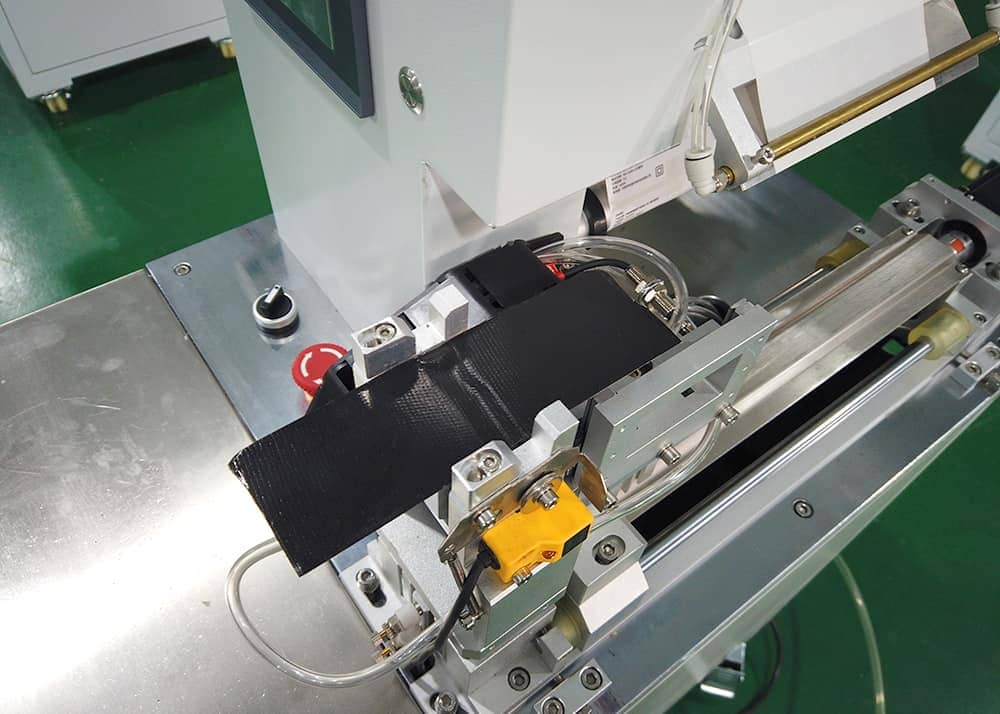

Self adhesive label machines are designed to apply labels that have a sticky backing, eliminating the need for additional adhesives or water to activate the label. This technology streamlines the labeling process, making it faster and more efficient. The key features that set these machines apart include their precision, ease of use, and ability to handle various label types and materials.

With the right self adhesive label machine, you can achieve consistent and accurate label placement, which is crucial for maintaining product quality and compliance with industry standards. These machines are engineered to work seamlessly with different packaging types, from bottles to boxes, ensuring that labels are applied correctly every time.

Efficiency and Speed in Production

One of the primary benefits of a self adhesive label making machine is the significant boost in production speed. Traditional labeling methods often involve multiple steps and manual intervention, which can slow down the entire process. In contrast, self adhesive label machines automate the labeling process, reducing the time needed to label each product and allowing for a higher throughput.

By minimizing downtime and increasing the speed of labeling, these machines can dramatically improve your production efficiency. This is especially important in high-volume manufacturing environments, where even small gains in speed can translate into substantial cost savings and increased output.

Cost-Effectiveness Over Time

While the initial investment in a self adhesive label machine may seem significant, the long-term cost savings are well worth it. These machines reduce the need for manual labor, which can lower your overall operating costs. Additionally, they minimize waste by ensuring that labels are applied accurately and consistently, reducing the likelihood of costly rework or product recalls.

When you compare the operational costs of self adhesive label machines with traditional labeling methods, the advantages become clear. Over time, the machine pays for itself through reduced labor costs, increased efficiency, and improved product quality.

Enhancing Product Presentation

A well-applied label can enhance the overall look of your product, making it more appealing to potential customers. Self adhesive label machines ensure that labels are applied uniformly and without wrinkles or bubbles, giving your products a professional appearance.

In addition to improving aesthetics, consistent labeling also helps to build brand trust. When customers see that your products are labeled with care and precision, they are more likely to view your brand as reliable and of high quality.

Versatility Across Industries

Self adhesive labelling machines are not limited to one type of industry; their versatility makes them suitable for a wide range of applications. Whether you’re in the food and beverage sector, pharmaceuticals, cosmetics, or any other industry that requires precise labeling, these machines can be adapted to meet your specific needs.

Their ability to handle various materials, from paper to plastic, and different label sizes means that you can use the same machine for multiple products. This versatility not only increases the machine’s value but also allows you to streamline your labeling operations across different product lines.

Ease of Use and Minimal Training Requirements

One of the standout features of self adhesive label machines is their user-friendly design. These machines are engineered to be easy to operate, even for employees with minimal technical expertise. Most machines come with intuitive controls and simple interfaces, allowing operators to quickly learn how to use them.

This ease of use translates into minimal training requirements, meaning that your workforce can start using the machine almost immediately after installation. This quick learning curve helps to reduce downtime and ensures that your labeling operations continue without interruption.

Environmentally Friendly Labeling Solutions

Self adhesive label machines offer several sustainability benefits, making them an eco-friendly choice for your labeling needs. These machines typically use labels made from recyclable materials and reduce waste by ensuring precise application.

By investing in a self adhesive label machine, you can contribute to a more sustainable manufacturing process, which is not only good for the environment but also for your brand’s reputation.

Customization and Flexibility

Another major advantage of self adhesive label machines is their customization capabilities. These machines allow you to tailor your labeling process to meet the specific needs of your products. Whether you need to apply labels in a particular location on the packaging or use custom-designed labels, these machines offer the flexibility to do so.

This level of customization ensures that your products stand out on the shelf and meet all regulatory requirements. It also allows you to adapt quickly to changes in your product line or labeling regulations, ensuring that your labeling operations remain compliant and efficient.

Boosting Business Competitiveness

In today’s competitive market, staying ahead of the competition is essential. Investing in advanced labeling technology, like a self adhesive label machine, can give your business the edge it needs to succeed. These machines not only improve your production efficiency but also enhance the overall quality of your products.

With a self adhesive label machine, you can ensure that your products are labeled with precision and consistency, which can help you build a strong brand reputation. This, in turn, can lead to increased market share and profitability, helping your business thrive in a competitive environment.

Conclusion

Investing in a self adhesive label machine is a strategic decision that offers numerous benefits. From improving production efficiency to enhancing product presentation, these machines are an invaluable asset for any business looking to stay competitive in today’s market. By choosing the right machine, you can achieve long-term cost savings, boost your brand’s reputation, and contribute to a more sustainable future.