The LBM-SXY-1102 100-Hole Manual Capsule Filler is perfect for small-batch production of capsules, featuring easy operation and complete control over the capsule filling process.

| Weight | 820 kg |

|---|---|

| Dimensions | 165 × 165 × 65 mm |

| Model | LBM-SXY-1102 |

| Filling Type | Volumetric filling |

| Capsule Type | Capsules (suitable for filling powders) |

| Applicable Industries | Food, pharmaceutical |

| Color Options | Blue, green, yellow, beige |

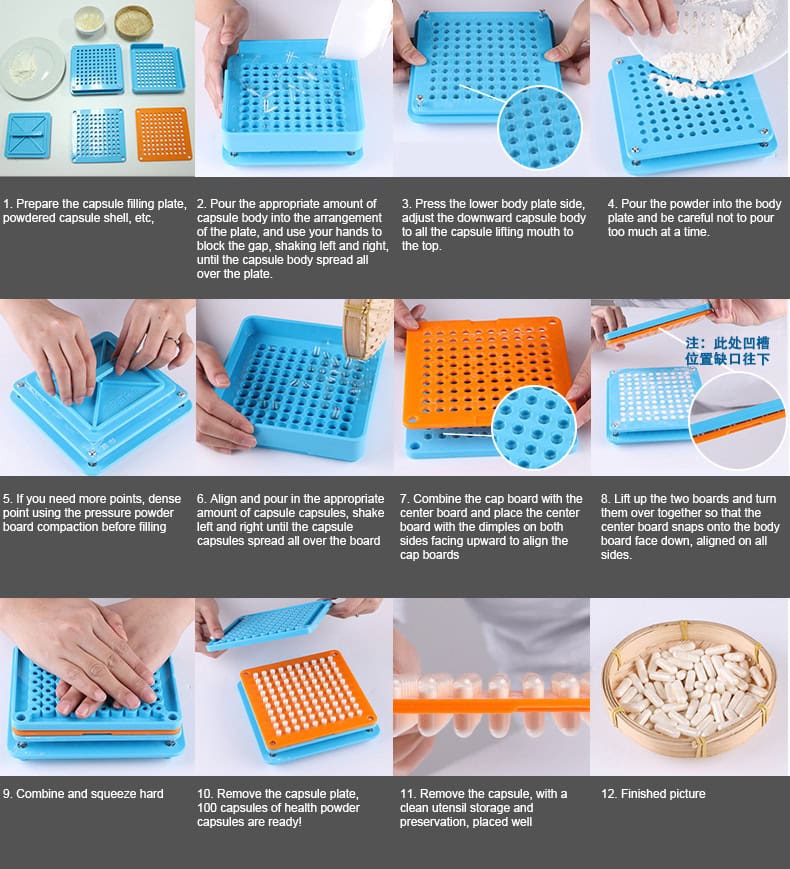

The 00# 100-Hole Large Manual Capsule Filler LBM-SXY-1102 is an efficient tool designed for small-batch production of capsules, suitable for both personal use and small-scale pharmaceutical production. It is widely used in the food and pharmaceutical industries for filling capsules with powdered substances like medicine or supplements.

The machine is easy to operate and comes in various colors: blue, green, yellow, and beige. The complete set includes multiple components such as a powder pressing plate, alignment plate, middle plate, cap plate, body plate, and powder scraper.

|

Model:

|

LBM-SXY-1102

|

|

Weight:

|

820 kg

|

|

Dimensions:

|

165mm x 165mm x 65mm

|

|

Filling Type:

|

Volumetric filling

|

|

Capsule Type:

|

Capsules (suitable for filling powders)

|

|

Applicable Industries:

|

Food, pharmaceutical

|

|

Color Options:

|

Blue, green, yellow, beige

|

LabeMachine is a specialized manufacturer of labeling machines and complementary equipment. Our main products include wire labeling machines, bottle labeling machines, flat labeling machines, packaging machines, and filling machines. We are committed to providing high-quality, reliable solutions for all your labeling and packaging needs. more+

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more