The Manual Capsule Filling Machine is a cost-effective and versatile solution for small to medium-scale capsule production. It offers easy operation and flexibility, ideal for businesses in the pharmaceutical, supplement, and nutraceutical industries.

The Manual Capsule Filling Machine is an essential tool for small to medium-scale production operations, commonly used in the nutraceutical, pharmaceutical, and supplement industries. This machine is designed for manually filling empty capsules with powder or granular substances, offering an affordable and flexible solution for businesses that require a more hands-on approach to capsule filling.

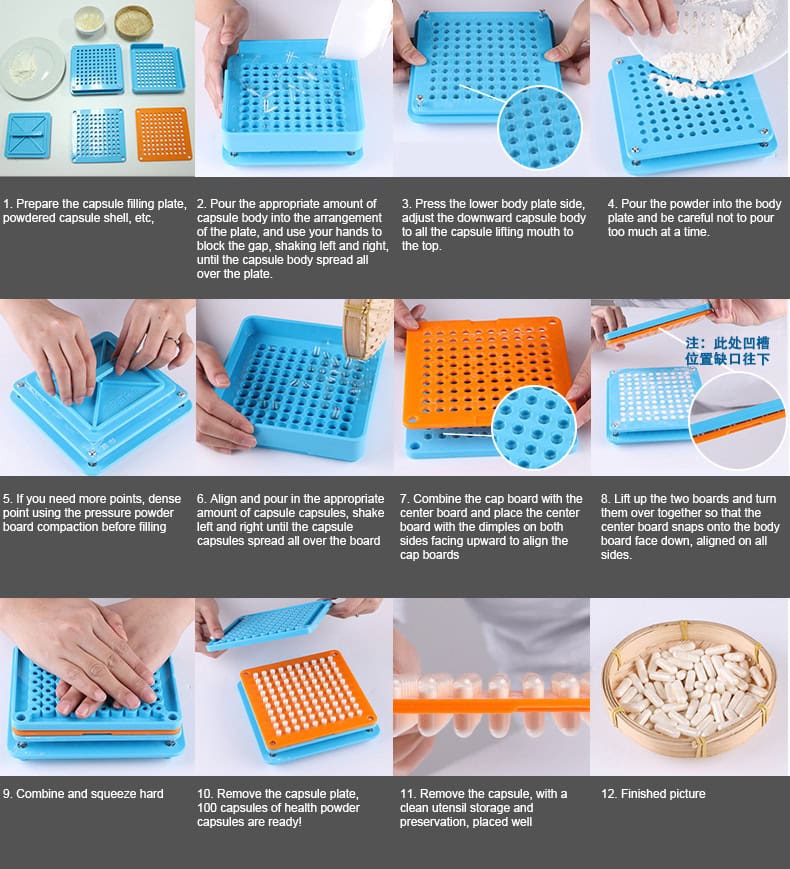

The Manual Capsule Filling Machine operates through the following steps:

LabeMachine is a specialized manufacturer of labeling machines and complementary equipment. Our main products include wire labeling machines, bottle labeling machines, flat labeling machines, packaging machines, and filling machines. We are committed to providing high-quality, reliable solutions for all your labeling and packaging needs. more+

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more