Struggling to choose the right labeling machine leads to wasted time and budget, directly affecting business efficiency. A well-matched desktop round bottle labeling machine can optimize production and costs effectively.

To choose a suitable desktop round bottle labeling machine, consider factors like bottle size, label type, speed requirements, machine precision, and operational budget.

Let’s explore these critical factors in detail to ensure you select the best machine for your business.

Determine Your Production Needs

Understanding your production scale is essential. For small-scale operations, a semi-automatic bottle labeling machine may suffice, as it offers moderate speed and affordability. However, if you manage a larger production line, consider fully automated machines that can handle higher volumes efficiently.

Matching the machine’s speed with your output requirements prevents overinvestment in unnecessary capacity or bottlenecks caused by slow machinery.

Evaluate Labeling Precision

Labeling precision ensures consistency and professionalism. Desktop machines offering high labeling accuracy, such as ±0.5 mm, deliver flawless label placement. This precision is critical in industries like pharmaceuticals and food packaging, where accurate labeling is essential for compliance and branding.

Investing in a machine with advanced sensors and precision mechanisms minimizes rework and improves operational efficiency.

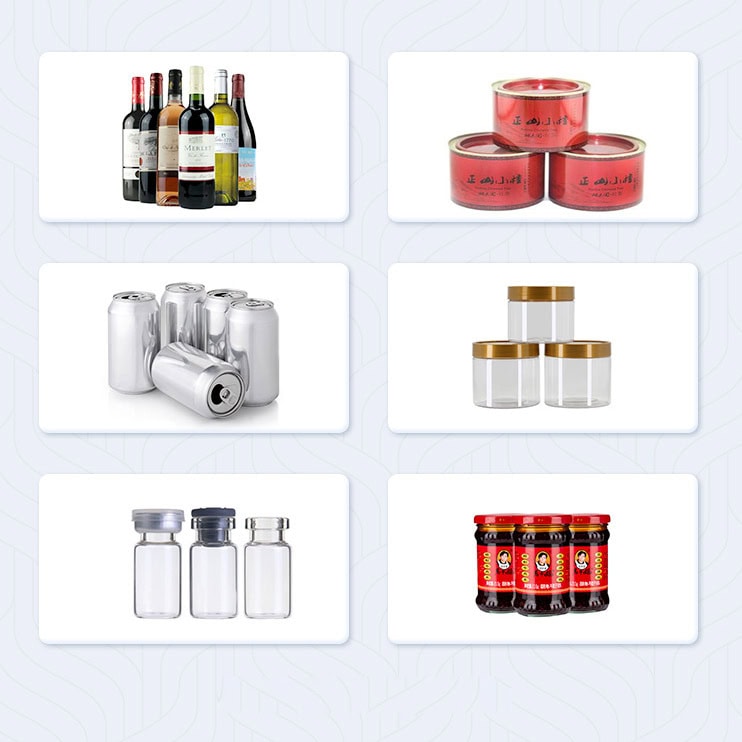

Understand Bottle and Label Compatibility

Bottle dimensions and label specifications must align with the machine’s capabilities. Machines should accommodate cylindrical bottles of varying diameters and support different label types, including self-adhesive and film labels. For example, a flag labeling machine can be a versatile option for more complex labeling needs.

Check the machine’s adaptability for different bottle shapes to future-proof your investment.

Analyze Speed and Efficiency

The speed of a labeling machine directly impacts production throughput. Desktop round bottle labeling machines typically label 15–60 bottles per minute. Evaluate this speed against your daily production targets.

For businesses integrating labeling with other equipment like filling machines or capping machines, ensuring compatible speeds is crucial for a seamless workflow.

Space and Operational Requirements

A compact and lightweight machine is ideal for limited workspace environments. Review machine dimensions and ensure sufficient clearance for operation and maintenance. Confirm compatibility with your facility’s voltage supply and air pressure systems, as these affect operational stability.

Machines with a simplified setup and easy access for adjustments reduce downtime significantly.

Budget Considerations

Choose a machine that balances cost and functionality. While price is a key factor, do not compromise on critical features like durability or precision. Consider long-term costs such as maintenance, spare parts, and potential downtime.

For cost-conscious buyers, explore models from reputable manufacturers offering economical yet reliable machines tailored to your needs.

Ease of Operation

Look for user-friendly features such as intuitive touch screens, clear labeling setup processes, and easy troubleshooting. Operators can quickly learn to use these machines, reducing training time and labor costs.

Machines with minimal maintenance requirements, like automated label sensors or tool-free adjustments, enhance productivity.

Durability and Build Quality

Durable materials like stainless steel and aluminum alloys provide structural integrity and extend the machine’s lifespan. Industrial-grade components withstand the wear and tear of continuous use.

Choosing a machine built with high-quality parts ensures stable performance, even in demanding environments.

Manufacturer Support and Warranty

Reliable after-sales support and warranty services are crucial. Partner with manufacturers that offer responsive technical support, comprehensive manuals, and readily available spare parts.

This ensures minimal downtime and quick resolutions to any operational challenges.

Adaptability and Future-Proofing

Invest in machines with flexible configurations. Features such as dual-label modes, adjustable label positions, and compatibility with various label sizes allow for diverse applications.

This adaptability is especially valuable for businesses that may expand their product lines in the future.

Conclusion

Selecting the right desktop round bottle labeling machine requires balancing production needs, budget, and future goals. Evaluate features comprehensively and choose a reliable machine to maximize efficiency and ensure long-term success.