Handling small bottles in an automated production line can cause you a lot of problems. If you can’t handle the bottles, they get misaligned and slow down your operation. That’s not what you want. You want to keep the bottles flying through your production line.

Micro-bottle unscramblers will help you handle small bottles. With these machines, you’ll be able to process bottles much faster and more accurately than you can by doing it by hand.

This article tells you how these machines work, the benefits you get, and what you need to know to select a micro-bottle unscrambler for your operation.

How Micro-Bottle Unscramblers Work

Micro-bottle unscramblers are machines used to automate the process of feeding and orienting small bottles into your production line. They make sure the bottles are all lined up and ready to go to the next step in your production line. This reduces the need for you to have people standing there lining up the bottles, and it speeds up the process.

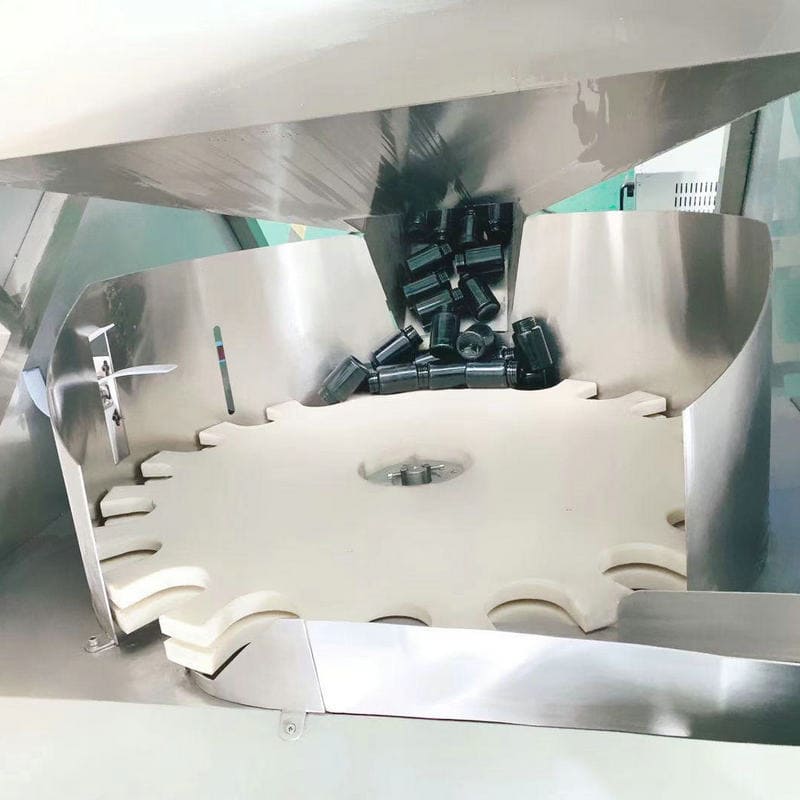

The main parts of these machines are rotary systems, sensors, and programmable logic controllers (PLCs). Bottles are loaded into a hopper where they are sorted and lined up using rotating discs or conveyor belts. Sensors detect where the bottles are and make sure they’re lined up properly. The PLC controls the whole thing to make sure it all works together seamlessly to handle the bottles.

Benefits of Using Micro-Bottle Unscramblers

Increased Production Efficiency

One of the primary benefits of micro-bottle unscramblers is the significant increase in production efficiency. These machines are capable of processing thousands of bottles per hour, far surpassing the capabilities of manual labor. By automating the unscrambling process, businesses can minimize bottlenecks and keep production lines running at full capacity.

Minimizing Human Errors

Automated unscramblers ensure that each bottle is correctly oriented before it enters the production line. This eliminates the risk of human errors, such as incorrect bottle placement or misalignment, which can cause delays and product defects. With micro-bottle unscramblers, every bottle is consistently placed in the correct position, ensuring seamless operation.

Key Features of a High-Quality Micro-Bottle Unscrambler

High Speed and Accuracy

Micro-bottle unscramblers are designed to operate at high speeds, handling thousands of bottles per hour while maintaining precision. They use advanced sensors to detect bottle positioning and make real-time adjustments, ensuring that each bottle is aligned correctly before moving to the next stage.

Customizable Settings

A good micro-bottle unscrambler offers customizable settings to meet different production needs. For example, operators can adjust the speed of the unscrambler to match the production line’s output. Additionally, many machines can be configured to handle a wide range of bottle sizes and shapes, providing flexibility in production.

Micro-Bottle Unscrambler Technology

Modern micro-bottle unscramblers utilize servo motors and sensors to enhance precision and efficiency. Servo motors provide fine control over the movement of bottles, allowing the machine to handle small, fragile bottles without damaging them. Sensors play a crucial role in detecting bottle orientation and ensuring that each bottle is positioned correctly before moving forward.

Some models also feature automated fault detection systems, which halt the machine if a misfeed occurs, preventing damage to the bottles or the machine itself. This not only protects the equipment but also ensures uninterrupted production.

Considerations for Choosing the Right Unscrambler

Machine Size and Layout

When selecting a micro-bottle unscrambler, it’s important to consider the size and layout of the machine. Compact models are ideal for facilities with limited space, as they can be easily integrated into existing production lines without requiring significant modifications.

Bottle Compatibility

Not all micro-bottle unscramblers are compatible with every type of bottle. Before purchasing a machine, ensure that it supports the size and shape of the bottles used in your production line. Look for models that offer adjustable components to accommodate a variety of bottle dimensions.

Popular Micro-Bottle Unscrambler Models

Posimat Micro Unscrambler

The Posimat Micro Unscrambler is known for its compact design and high-output capacity. It is capable of processing thousands of small bottles per hour, making it an excellent choice for industries requiring fast and efficient bottle handling. Its compact size allows for easy integration into existing production lines.

Lanfranchi Unscrambler

Lanfranchi’s unscramblers are highly customizable, allowing operators to adjust settings based on the specific needs of their production line. These machines are built to handle a wide variety of bottle sizes and shapes, ensuring compatibility with almost any small bottle.

SB-6000 from SMF GmbH

The SB-6000 unscrambler features advanced feeding technology, ensuring smooth operation even at high speeds. It is designed to integrate seamlessly with other production line equipment, offering excellent flexibility and efficiency.

Industries Benefiting from Micro-Bottle Unscramblers

Pharmaceutical Industry

Micro-bottle unscramblers are widely used in the pharmaceutical industry for handling small vials and bottles. Their precision and reliability ensure that delicate containers are handled with care, reducing the risk of contamination or breakage.

Beverage Industry

In the beverage industry, micro-bottle unscramblers are essential for processing small beverage containers. These machines can handle high production volumes, helping beverage companies meet demand while maintaining quality standards.

Cosmetics Industry

The cosmetics industry often deals with uniquely shaped bottles, which can be difficult to handle manually. Micro-bottle unscramblers provide the necessary precision and flexibility to ensure that even irregularly shaped bottles are properly oriented for labeling and filling.

Conclusion

You need a micro-bottle unscrambler if you’re going to automate your operation. These machines will help you handle small bottles fast and accurately.