Zebra printers are renowned for their efficiency, but many people wonder how they can print without using traditional ink. Without the proper understanding of thermal printing technology, businesses risk inefficiency and high operational costs. Fortunately, Zebra printers use thermal technology, which eliminates the need for ink, offering a cost-effective and reliable solution for printing labels, receipts, and more.

Zebra printers use thermal printing technology to print labels without ink. They rely on heat to activate a special coating on thermal paper or labels, which results in clear, precise prints.

To fully understand how Zebra printers operate, let’s dive deeper into the mechanisms behind thermal printing and why it’s a superior choice for many businesses.

What is a Zebra Printer and How Does it Work?

Zebra printers are thermal printers designed for high-quality, high-speed printing without the need for ink or toner. They are commonly used in industries like retail, logistics, and healthcare to print labels, tags, and receipts. By leveraging thermal printing technology, Zebra printers eliminate the ongoing costs and mess associated with traditional ink-based printing methods.

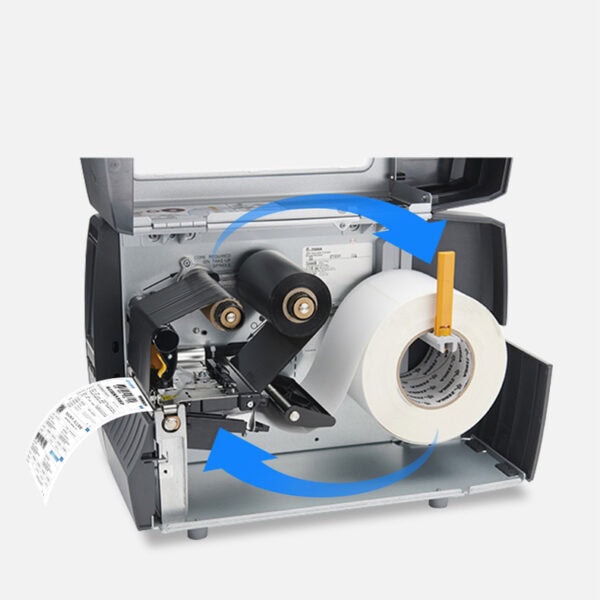

Zebra printers operate using two main types of thermal printing: direct thermal and thermal transfer printing. In direct thermal printing, heat is applied directly to a special heat-sensitive paper, causing the paper to darken in the areas exposed to heat. In thermal transfer printing, the heat transfers ink from a ribbon to the material being printed, creating a durable print that can withstand wear and tear.

Key Types of Zebra Printers

- Direct Thermal Printers: These printers work by applying heat directly to thermal paper, which turns black when exposed to the heated printhead. This method is cost-effective and is ideal for applications like receipts, tickets, and short-term labels. Since there’s no need for ink or ribbons, it simplifies maintenance and reduces costs.

- Thermal Transfer Printers: Unlike direct thermal printers, these printers use a heat-sensitive ribbon to transfer ink onto the label or paper. The result is a more durable and long-lasting print that can endure exposure to harsh environmental conditions like high humidity, abrasion, or sunlight. This makes thermal transfer printers ideal for applications where durability is a priority.

- Hybrid Printers: Some Zebra printers offer the flexibility of both direct thermal and thermal transfer printing. This allows businesses to switch between methods depending on the specific needs of the application.

How Do Thermal Printers Work Without Ink?

Thermal printers, such as Zebra printers, do not require traditional ink or toner. Instead, they rely on heat to create prints. In direct thermal printing, the printhead generates heat, which is applied to the thermal paper. The paper contains a special coating that changes color when heated, forming the desired text or image. In thermal transfer printing, the printhead transfers ink from a ribbon to the material being printed. This creates a print that is more durable and resistant to fading.

Key Components of Zebra Printers

- Printhead: This is the heart of the thermal printer, responsible for generating heat. It consists of a series of tiny heating elements that heat up in response to the print command, creating the image or text on the material.

- Thermal Paper or Ribbon: The material used in thermal printing is either heat-sensitive paper or a ribbon. Direct thermal printers use paper that reacts to heat, while thermal transfer printers use a ribbon that releases ink when heated.

- Sensors: Zebra printers are equipped with sensors that ensure the proper alignment of the labels and paper, ensuring that the print is accurate and clear.

Benefits of Zebra Printers Over Ink-Based Printers

Zebra printers offer several advantages over traditional inkjet or laser printers.

- No Ink or Toner Required: Zebra printers eliminate the ongoing costs of ink cartridges or toner refills. This makes them a cost-effective solution for businesses that need to print large volumes of labels, receipts, or tags. Additionally, the absence of ink means there is no risk of ink smudging or fading, ensuring long-lasting prints.

- Faster Printing: Thermal printers generally operate faster than inkjet or laser printers, making them ideal for high-volume applications in environments such as warehouses, logistics centers, and manufacturing facilities. The quick speed helps improve efficiency in industries that rely on high throughput.

- Low Maintenance: With fewer consumables and moving parts, Zebra printers require less maintenance than ink-based printers. This leads to fewer breakdowns and less downtime, increasing productivity in a business setting.

- Durability: Prints created by Zebra printers, especially those using thermal transfer technology, are often more resistant to smudging, fading, and water damage than inkjet prints. This makes Zebra printers the preferred choice for applications in harsh conditions, such as manufacturing or logistics.

What Are Zebra Printers Used For?

Zebra printers are versatile and are used across a range of industries, including retail, healthcare, and manufacturing.

- Retail and Logistics: Zebra printers are commonly used to print shipping labels, barcodes, and price tags. Their ability to produce high-quality, legible prints quickly makes them ideal for fast-paced retail environments. Additionally, Zebra printers help streamline inventory management and shipment tracking.

- Healthcare: In the healthcare sector, Zebra printers are used for printing patient wristbands, medication labels, and specimen tags. The accuracy and reliability of Zebra printers are crucial for patient safety and compliance with healthcare regulations.

- Manufacturing: Zebra printers play an essential role in manufacturing for tasks such as labeling products, packaging, and asset tracking. The ability to print durable labels that can withstand environmental stress is particularly important in this industry.

How Does Zebra Printer’s “Browser Print” Feature Work?

Zebra’s Browser Print feature allows users to print directly from a web browser to a Zebra printer without needing additional software. This capability simplifies the printing process, particularly for businesses using web-based systems or cloud platforms.

How it Works

To print using the Browser Print feature, users simply send the print command from the web browser to the Zebra printer over a network. The printer then processes the data and produces the printout without the need for complicated configurations. This feature makes Zebra printers particularly user-friendly and adaptable to a wide range of applications.

Do Thermal Printers Need Ink?

Thermal printers, including Zebra printers, do not require ink or toner. Instead, they use heat to generate prints. This makes them inherently more cost-effective and reliable than inkjet or laser printers. Thermal printers are particularly useful for printing labels, tags, and receipts, where high-speed printing and durability are important.

Zebra Thermal Printer vs. Inkjet Printers

- Printing Technology Comparison: Inkjet printers rely on liquid ink, which is sprayed onto the paper. In contrast, Zebra printers use heat to print on thermal materials. This makes thermal printers more efficient and less messy than inkjet printers.

- Cost and Maintenance: Thermal printers like Zebra models are more cost-effective over time. There’s no need to constantly replace ink cartridges or toner. Moreover, their simple construction means less maintenance is required, resulting in fewer downtime and lower operating costs.

- Print Quality and Durability: Zebra printers, especially those that use thermal transfer printing, produce prints that are more durable than inkjet prints. Thermal prints are resistant to fading and smudging, making them ideal for long-lasting labels and packaging.

How Does Thermal Paper Work?

Thermal paper is a special kind of paper that has a heat-sensitive coating. When heat is applied by a printhead, the paper changes color in the heated areas, forming the desired text or image. This type of paper is commonly used in receipts, labels, and tickets.

Durability and Applications

While thermal paper prints are highly durable in most conditions, they can fade over time if exposed to heat or sunlight. However, thermal paper is ideal for short-term applications like receipts or labels, and it’s often used in environments that require quick, efficient printing, such as retail or hospitality.

Do Zebra Printers Work for All Types of Printing Needs?

Zebra printers excel in applications that require fast, reliable, and cost-effective printing. However, they may not be suitable for printing high-resolution images or color graphics, which are better suited for inkjet or laser printers. Zebra printers are optimized for printing labels, barcodes, and other industrial tags, making them a great fit for businesses in logistics, retail, and manufacturing.

Zebra offers a range of customizable solutions to meet specific business needs. Whether you’re looking for a flag labeling machine, a bottle labeling machine, or even a customized labeling machine, Zebra printers can be tailored to your exact requirements.

Conclusion

Zebra printers use thermal technology to print labels and other materials efficiently and cost-effectively. Their ability to operate without ink or toner makes them an attractive option for businesses that require high-speed, low-maintenance printing solutions. Whether you need a labeling machine, a packaging machine, or a filling machine, Zebra printers offer a reliable, durable solution for a wide range of applications.