Many buyers question the reliability of Chinese packaging machines, particularly due to concerns about quality, maintenance, and after-sales support.

With a vast selection of machinery options and the potential for significant cost savings, it’s natural to wonder if Chinese-made packaging equipment can truly meet the demands of modern industries.

In this article, we’ll explore the strengths and considerations of Chinese packaging machines, and what you should know before investing.

Improved Quality Standards in Chinese Packaging Machines

Chinese packaging machines have greatly improved in quality over the years. Manufacturers have embraced advanced production techniques, implementing rigorous quality control processes that ensure reliability and durability.

This shift means that buyers can now find equipment that aligns with global standards, offering reliable performance and competitive pricing. A good example is labeling machines, which often come with quality certifications like ISO and CE, demonstrating compliance with international quality and safety standards.

Affordability and Cost-Effectiveness

One of the most significant benefits of purchasing packaging machines from China is the cost-effectiveness. Chinese machinery typically costs less than Western counterparts, often without compromising on quality or functionality.

This affordability makes it an attractive choice for small to medium enterprises or businesses looking to expand their operations without a massive investment. For example, a powder packaging machine from a reliable Chinese manufacturer can achieve the same level of efficiency at a fraction of the price.

Wide Range of Options and Customization

Chinese manufacturers offer an extensive range of packaging solutions, including machines for various packaging styles and sizes. From liquid filling machines to customizable wrapping and labeling machines, there’s a solution for virtually every packaging need.

Many manufacturers are also willing to tailor their machines to meet specific requirements, providing businesses with the flexibility to achieve customized packaging solutions. This adaptability is especially beneficial for companies needing unique configurations for niche products or specialized packaging formats.

Global Standards Compliance

Many reputable Chinese manufacturers adhere to international standards, including ISO certifications, CE marking, and FDA approvals. This compliance is crucial for businesses looking to enter markets that require specific safety and quality standards.

With advanced testing and adherence to these guidelines, Chinese packaging machines have gained acceptance in industries such as food and beverage, pharmaceuticals, and cosmetics.

Ease of Operation and User-Friendly Designs

Chinese packaging equipment has become increasingly user-friendly, with most machines designed with intuitive interfaces. Many machines feature touchscreens and support for multiple languages, making it easier for operators around the globe to manage settings and troubleshoot.

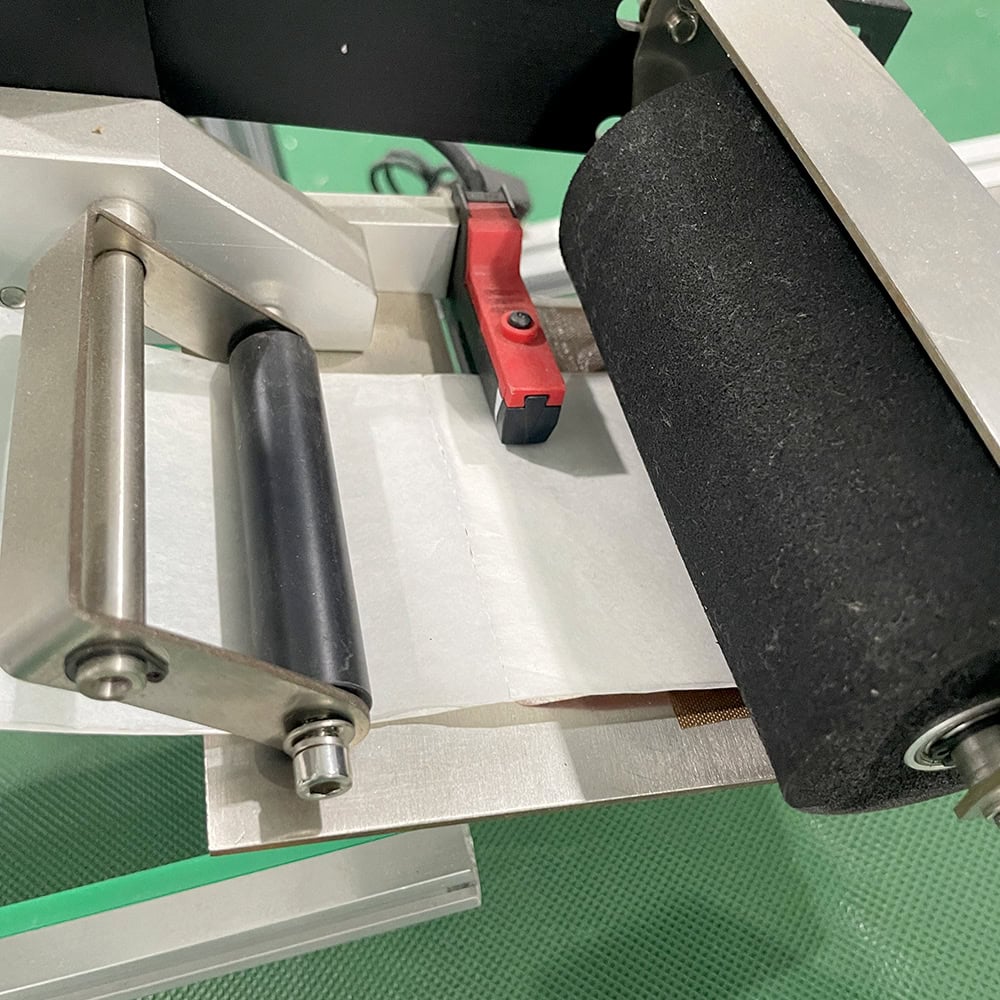

Manufacturers often include comprehensive manuals and video tutorials, simplifying setup and training processes. For instance, a flat labeling machine from China can be set up within hours and easily integrated into existing production lines.

Technological Advancements and Automation

The recent advancements in automation and technology have transformed Chinese packaging machines, making them highly competitive on the global stage. With features like programmable logic controllers (PLC), automation of various stages, and integration with smart production systems, Chinese packaging machines offer enhanced productivity and reduced human error.

For businesses with high production demands, automated options like industrial label printers and vacuum packaging machines are available, offering streamlined processes and increased output.

Dependable After-Sales Service and Support

Many established Chinese manufacturers now offer comprehensive after-sales service, including remote support, replacement parts, and maintenance plans.

This improved support network is key to sustaining long-term reliability, as timely assistance can minimize downtime and extend the life of the machinery. Furthermore, companies often provide online technical support, ensuring that machine operators have assistance when issues arise.

Customizable Quality Levels and Options for Upgrades

Chinese packaging machine suppliers offer various quality levels and options to fit different budgets and functional needs. Machines can often be upgraded or modified with additional features like automated capping or high-speed labeling for higher output demands.

This flexibility allows businesses to select machines that can grow with their production needs, and manufacturers frequently provide guidance on which upgrades may be beneficial.

Trusted and Experienced Manufacturers

Reputation is everything in the packaging machine industry. By choosing experienced manufacturers with a proven track record, buyers can mitigate the risk of purchasing subpar equipment. Many companies provide references, quality certifications, and warranty information to establish trust. Websites that specialize in machine reviews and feedback are also useful for verifying a manufacturer’s reliability.

Practical Considerations When Importing from China

When purchasing packaging machines from China, logistics and customs considerations are important. Choosing a trusted manufacturer who offers quality inspection before shipment can ensure that machines arrive in optimal condition.

Additionally, understanding the import regulations and preparing for possible delays due to customs processes can make the transaction smoother. Some manufacturers even assist with shipping and offer insurance to safeguard the machinery in transit.

Conclusion

Chinese packaging machines have become a viable option for businesses worldwide, providing an impressive balance of quality, affordability, and functionality.

By carefully selecting trusted manufacturers and ensuring that machines meet international standards, businesses can benefit from the reliability of Chinese packaging equipment and enjoy significant cost savings. With the right approach, Chinese-made packaging machines can support high-performance production for years to come.