Inefficient labeling processes for square bottles can lead to production delays and inconsistent results. This disrupts supply chains and affects brand image. A square bottle labeling machine provides a reliable solution, offering precision, speed, and versatility to meet industry demands.

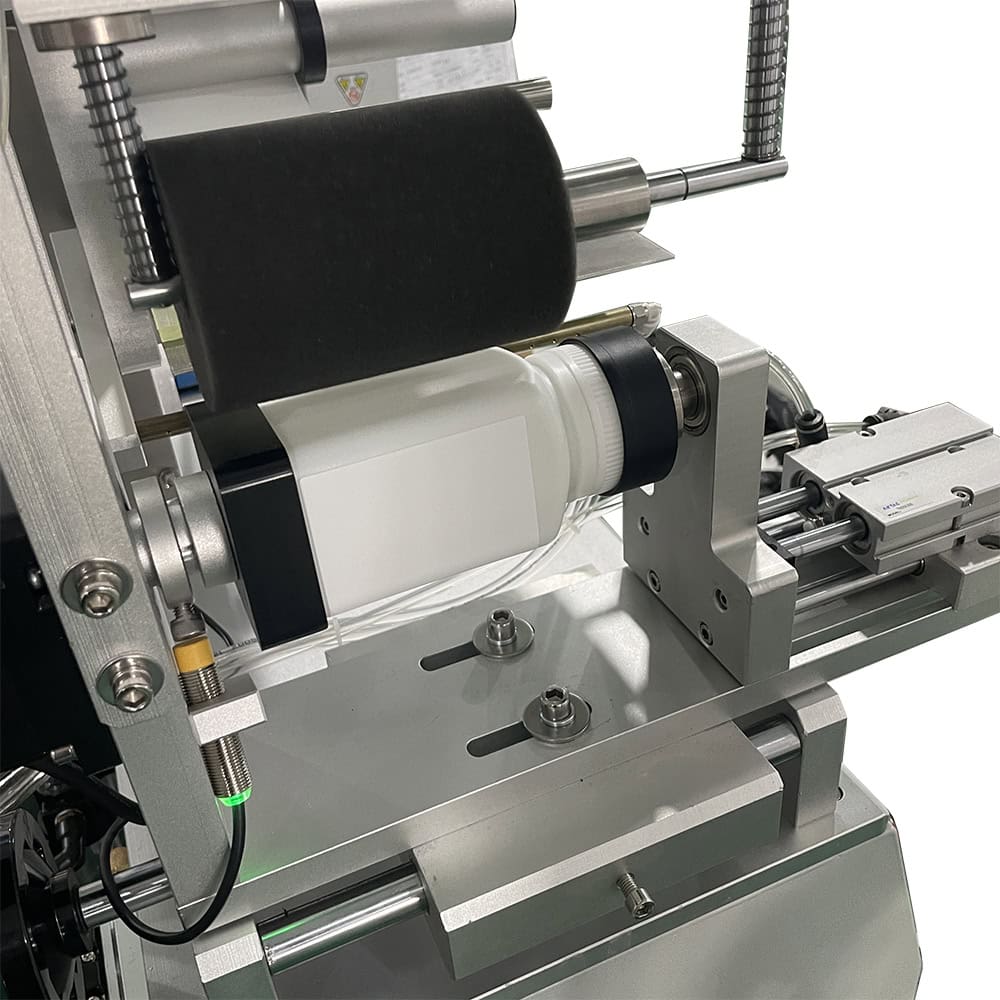

A square bottle labeling machine ensures precise and efficient labeling for various bottle sizes and shapes, supporting single, double, or multi-sided labels with high speed and accuracy.

Explore the comprehensive features and applications of these machines to understand why they are an essential component for modern production lines.

Key Characteristics of Square Bottle Labeling Machines

High Labeling Accuracy

Square bottle labeling machines achieve exceptional precision, typically within ±0.3mm to ±1mm, ensuring that every label is positioned perfectly. This feature is crucial for maintaining professional and aesthetic packaging standards. Accuracy like this is especially beneficial in industries where product presentation plays a pivotal role, such as cosmetics or pharmaceuticals.

Adaptability for Various Bottle Sizes

These machines accommodate a wide range of bottle dimensions and label configurations. Whether labeling small bottles for pharmaceutical use or larger ones for beverages, the machine’s adjustable components ensure smooth operation across different sizes.

Versatile Labeling Options

Square bottle labeling machines are capable of applying single, double, or wrap-around labels. This versatility makes them suitable for various branding requirements, allowing businesses to meet diverse customer expectations.

Durable and Robust Design

Manufactured with premium materials like stainless steel and aluminum, these machines are built to last. Their robust construction minimizes wear and tear, even under high-intensity operations, ensuring long-term reliability.

User-Friendly Operation

Modern square bottle labeling machines feature intuitive touchscreens and adjustable settings. Operators can easily set parameters, monitor performance, and troubleshoot issues through user-friendly interfaces.

High Throughput Speed

Efficiency is key in production, and square bottle labeling machines deliver with labeling speeds of up to 1200 bottles per hour. This rapid performance helps businesses meet high-volume demands without compromising quality.

Automated Detection Features

Equipped with advanced sensors, these machines can detect bottle positions and sizes, ensuring accurate and consistent labeling. This automation minimizes human error and reduces waste.

Compatibility with Adhesive Labels

Square bottle labeling machines work seamlessly with various adhesive label types, including self-adhesive films and barcodes. This flexibility supports diverse labeling needs across industries.

Easy Maintenance

Designed for minimal downtime, these machines have accessible components that simplify routine maintenance. Clear instructions and robust construction further streamline the process, keeping operations running smoothly.

Customizable Configurations

Customization options, such as integration with a label printer or adding modules for flag labeling, expand the machine’s functionality. This makes them adaptable for unique production needs, such as those in specialized sectors like food or electronics.

Applications of Square Bottle Labeling Machines

Industries

Square bottle labeling machines are widely used in industries like:

- Pharmaceuticals: Ensuring compliance with strict labeling regulations.

- Cosmetics: Delivering aesthetic labels for premium products.

- Beverages: High-speed labeling for various bottle sizes.

- Food Packaging: Supporting diverse labeling requirements in food safety and branding.

Products

These machines are ideal for square bottles, cartons, and containers. They also support customizations for slightly curved or irregular surfaces, making them versatile for unique product lines.

Conclusion

Square bottle labeling machines are indispensable for businesses aiming to optimize their labeling processes. Combining speed, precision, and versatility, they ensure consistent results across various applications.