Packaging lines often face challenges in achieving consistent, high-quality labeling for cylindrical products. Without accurate label placement, products can appear unprofessional, and operational efficiency can suffer. The solution lies in wrap-around labelers, which streamline the labeling process and ensure precision.

Wrap-around labelers are specialized machines that apply labels around cylindrical products like bottles, cans, and jars. These systems provide accurate, efficient, and consistent labeling, essential for high-volume packaging lines.

Now, let’s explore how wrap-around labelers function, their benefits, and the different types available.

What is a Wrap-Around Labeler and How Does It Work?

Wrap-around labelers are designed to automatically apply labels around cylindrical objects, such as bottles or cans, ensuring complete coverage with precision and speed. These machines are essential for high-speed production lines, providing a solution to manual labeling errors and inefficiencies.

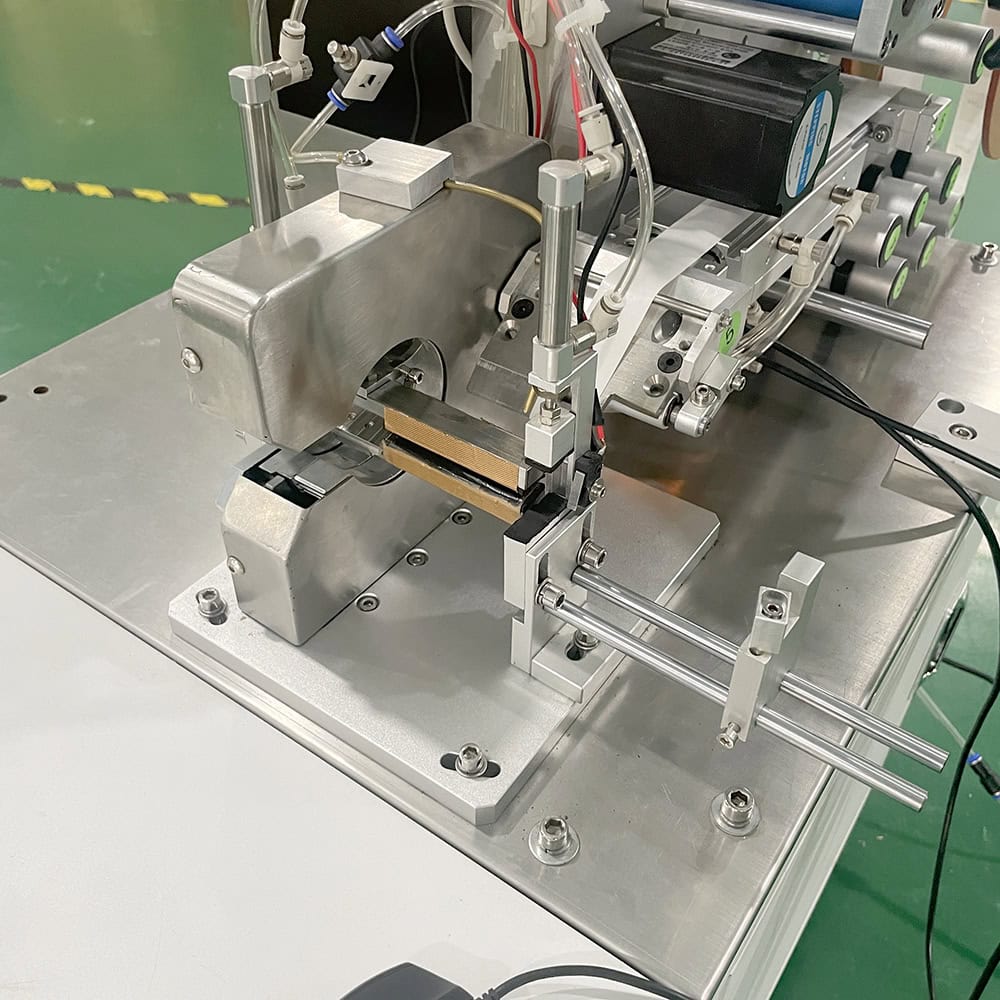

Wrap-around labelers use rotating conveyors and advanced sensors to align and apply the label accurately around cylindrical products. The machine’s rollers press the label onto the container, ensuring smooth, wrinkle-free application.

How Do Wrap-Around Labelers Work?

Wrap-around labelers use a series of rollers and sensors to ensure that the label is applied uniformly. The product is fed into the machine, where it rotates on a conveyor. The label is then automatically wrapped around the product, secured in place by adhesive. Advanced models can adjust to different product sizes and handle high-speed production.

For example, the CVC-300 bottle labeling machine offers excellent flexibility, accommodating various container sizes and shapes. This allows manufacturers to label products quickly and accurately, without wasting time or materials. Similarly, HERMA labelers are known for their precision, delivering high-quality results for businesses that demand perfection in packaging.

The automation provided by wrap-around labelers significantly reduces human error, ensuring a clean, consistent finish with minimal operator intervention. These machines can handle a wide range of labeling requirements, from small-scale operations to high-volume production.

What Types of Products Benefit from Wrap-Around Labeling?

Wrap-around labelers are ideal for products that require full-label coverage around cylindrical containers. These products range from beverages and cosmetics to pharmaceuticals and cleaning supplies.

Wrap-around labeling machines are perfect for cylindrical items such as bottles, jars, cans, and tubes. They ensure a smooth, tight application of the label, providing a polished finish that is both durable and professional-looking.

Common Products Using Wrap-Around Labelers

Wrap-around labelers are widely used in industries like food and beverage, cosmetics, and pharmaceuticals. These machines label items such as:

- Beverage bottles: Including juice, soda, and alcoholic drinks.

- Cosmetic jars: For products like lotions, shampoos, and creams.

- Pharmaceutical packaging: Labeling medicine bottles and containers.

The flexibility of these labelers makes them essential for companies looking to maintain high standards of labeling across multiple product types. Whether it’s a flat labeling machine or a corner wrap labeling machine, these systems are adaptable to various container shapes and sizes.

What Are the Key Advantages of Using a Wrap-Around Labeling System?

Wrap-around labelers offer several advantages, including improved production efficiency, reduced labeling errors, and enhanced product visibility. These benefits make them a crucial part of modern packaging lines.

The main advantages of wrap-around labelers are faster production speeds, high accuracy in labeling, and improved product presentation. These systems also offer the ability to handle different container sizes with minimal adjustment.

Why Choose Wrap-Around Labeling Systems?

One of the biggest advantages of wrap-around labeling is its speed. These machines can label products much faster than manual labor, which increases production efficiency. For example, the bottle labeling machine can apply labels to thousands of bottles in a short time, reducing bottlenecks in the packaging process.

Additionally, these machines ensure high-quality, consistent labeling, which improves brand presentation. Products with neatly applied labels stand out on shelves, attracting customers’ attention. The precision of wrap-around labelers also minimizes the chances of label misalignment, which can be costly for businesses.

Moreover, these machines are highly customizable, making them suitable for different products, container shapes, and sizes. Whether it’s a customized labeling machine or a simple bottle labeling machine, the versatility of these systems makes them invaluable to manufacturers across industries.

What Are the Different Types of Wrap-Around Labelers?

Wrap-around labeling machines come in various types, each designed to meet specific production needs. From manual to fully automated systems, businesses can choose the right type of machine depending on their production volume and labeling requirements.

There are manual, semi-automatic, and fully automatic wrap-around labelers, with each offering different levels of automation and customization.

Types of Wrap-Around Labelers

- Manual Labelers: These systems are typically used for low-volume production. Operators load the product and apply the label manually or with limited automation.

- Semi-Automatic Labelers: These machines combine manual loading with automated labeling. Semi-automatic labelers provide better efficiency while maintaining some flexibility for small batches.

- Fully Automatic Labelers: Ideal for high-volume operations, these machines automatically load, label, and unload products. Fully automated systems like vacuum packaging machines and filling machines can handle high-speed production with minimal human intervention.

Each type of wrap-around labeler has its own set of advantages, depending on the scale and needs of the production line. For large manufacturers, fully automated systems offer speed and precision, while smaller businesses might find semi-automatic systems more cost-effective.

Conclusion

Wrap-around labelers are essential for achieving high efficiency and accuracy in packaging lines, particularly for cylindrical products like bottles and cans. These systems ensure consistent labeling, enhance product visibility, and boost production speed, making them indispensable in modern packaging operations. Whether you need a bottle filling machine, a taping machine, or a customized labeling machine, wrap-around labelers are a valuable investment for any business looking to streamline their packaging process.