Manual flag labeling is inefficient, often leading to errors and delays. A Flag Printer Applicator automates the process, ensuring flawless application and saving time and resources.

What is a Flag Printer Applicator?

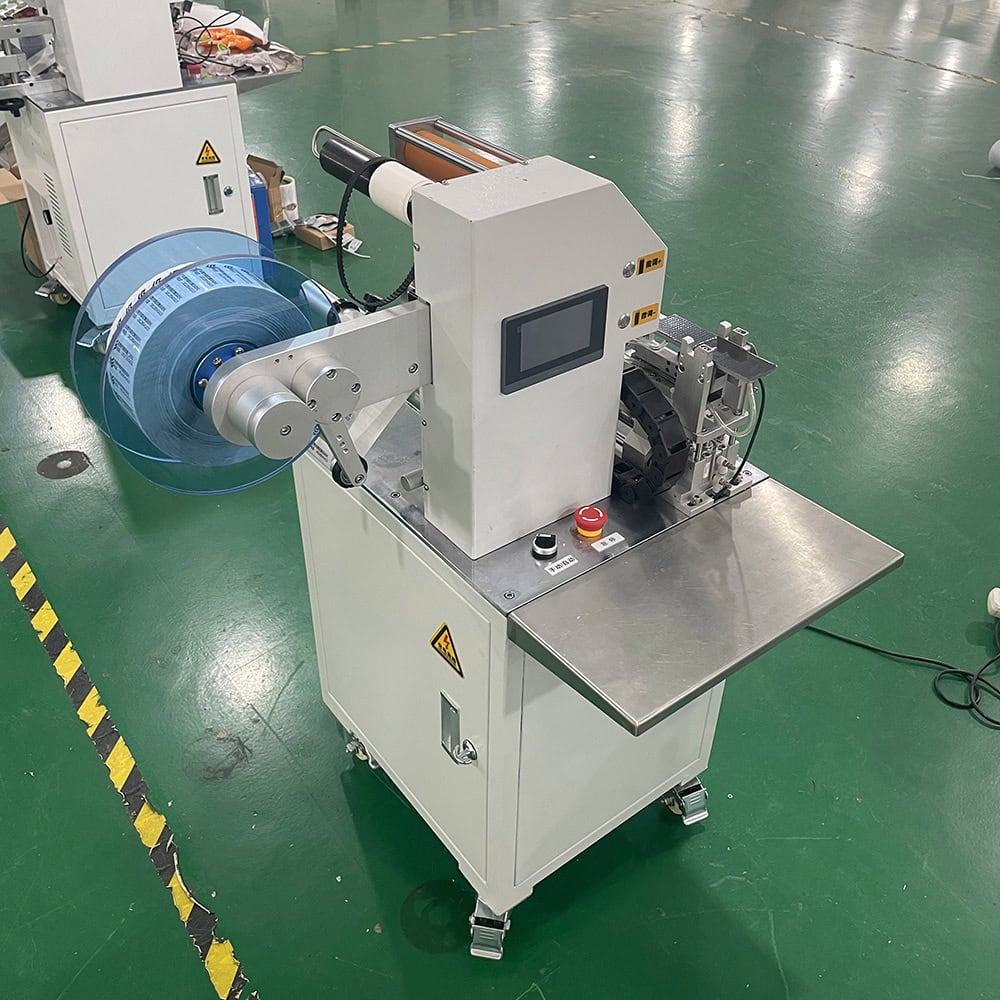

A Flag Printer Applicator is a specialized device that combines printing and application in one seamless operation. Designed for precision, it ensures labels wrap accurately around wires, cables, or tubes, creating durable and readable identifiers. Industries such as telecommunications, automotive, and manufacturing heavily rely on this technology to enhance workflow and minimize errors.

Key Features of Flag Printer Applicators

- High Precision: Advanced sensors and mechanisms ensure the label wraps evenly every time.

- Customizable Settings: Supports various label sizes and materials to fit different specifications.

- User-Friendly Interface: Intuitive controls make it easy to operate and adjust settings.

- Durability: Ensures long-lasting adhesion, even in demanding environments.

For example, the Brady A5500 offers exceptional speed and accuracy for high-volume labeling needs.

How Does a Flag Printer Applicator Work?

The Flag Printer Applicator operates in three main steps:

- Printing: High-quality printers produce text or barcodes on the label material.

- Peeling and Positioning: Labels are peeled from their backing and positioned accurately.

- Application: The machine wraps the label around the cable, ensuring a secure fit.

This integrated process eliminates manual handling, increasing both efficiency and accuracy.

Industries Benefiting from Flag Printer Applicators

- Telecommunications: Essential for identifying network cables and data lines.

- Automotive Manufacturing: Ensures traceability in complex wiring systems.

- Industrial Assembly: Provides consistent labeling for products in high-volume production lines.

Additionally, industries that use industrial label printers or flag labeling machines find these devices invaluable for maintaining compliance and operational efficiency.

Benefits of Using a Flag Printer Applicator

- Efficiency: Speeds up the labeling process, handling up to 1,500 labels per hour.

- Cost Savings: Reduces material waste and lowers labor costs.

- Improved Accuracy: Automated processes minimize human error.

- Versatility: Handles a wide range of label sizes, shapes, and materials.

Comparison with Manual Labeling Methods

| Feature | Manual Labeling | Flag Printer Applicator |

|---|---|---|

| Speed | Slow | Fast (up to 1,500 labels/hour) |

| Precision | Variable | Consistent |

| Labor Requirement | High | Low |

| Material Waste | High | Minimal |

Using an automated system like the flag labeling machine significantly enhances productivity and reduces overhead.

Maintenance and Calibration

Maintaining a Flag Printer Applicator is straightforward:

- Sensor Cleaning: Prevents misalignment and ensures proper operation.

- Calibration: Regularly adjust sensors and mechanisms for consistent label application.

- Software Updates: Keep firmware up-to-date to utilize the latest features.

For step-by-step calibration, refer to guides like How to Calibrate Your Printer for a seamless experience.

Challenges and Solutions in Flag Labeling

- Misaligned Labels: Adjust label sensors or peeling mechanisms for precise placement.

- Adhesive Issues: Use high-quality labels and ensure clean surfaces for better adhesion.

- Material Compatibility: Ensure the applicator settings match the label and product specifications.

Popular Models and Their Specifications

- Brady A5500: High-speed, versatile, and reliable for industrial needs.

- Panther Label Flag Applicator: Ideal for heavy-duty applications.

- Customizable Flag Labeling Machines: Tailored solutions for specific requirements.

Conclusion

A Flag Printer Applicator revolutionizes the labeling process, offering unparalleled speed, precision, and efficiency. By automating a traditionally manual task, it ensures high-quality results, making it an indispensable tool for industries focused on productivity and reliability. Whether you’re in telecommunications, automotive, or industrial manufacturing, adopting this technology can significantly enhance your operations.