Capping machines are vital for securing bottle caps and ensuring product safety in various industries. With countless manufacturers offering different types of capping solutions, selecting the best one for your business can be overwhelming. Let’s explore some of the top capping machine manufacturers and what makes them stand out.

The best capping machine manufacturers stand out for their quality, speed, and customer service. Industry leaders include iPharmachine, Massilly North America, and KULP Packaging, each offering unique solutions tailored to different needs and industries.

Now, let’s dive deeper into these manufacturers and explore what sets them apart in the competitive market of capping machine production.

What Makes a Capping Machine Manufacturer Stand Out?

To determine the best capping machine manufacturer, we need to look at various factors, such as technological innovation, product variety, customer support, and market reputation. These qualities can make a big difference in your production efficiency.

Top capping machine manufacturers distinguish themselves through their product innovation, speed, and after-sales services. They offer solutions for all types of caps, including screw caps, crown caps, and ROPP caps.

Factors to Consider When Choosing a Capping Machine Manufacturer

- Product Range

The best manufacturers offer a wide range of machines suitable for different cap types and container sizes. For example, iPharmachine offers both semi-automatic and fully automatic capping systems, ensuring flexibility in production. - Technological Innovation

Advanced features such as high-speed operation, torque control, and automatic size adjustments are critical in today’s market. Manufacturers like KULP Packaging focus on long-lasting, innovative machines that integrate stepper motors for precise cap placement. - Speed and Efficiency

Production speed is key in high-volume manufacturing. Leading brands, such as Closure Systems International, offer machines that cap at speeds of up to 1,200 bottles per minute, maximizing throughput and minimizing downtime. - Customer Support and After-Sales Services

Support is crucial for minimizing machine downtime. Top manufacturers provide excellent training, maintenance services, and troubleshooting support. iPharmachine, for instance, is known for its comprehensive after-sales support network, ensuring that customers get the most out of their equipment.

Who Are the Leading Capping Machine Manufacturers in the World?

Several manufacturers dominate the capping machine market. Let’s explore the top players and what makes them the preferred choice for many industries.

Top capping machine manufacturers such as iPharmachine, LabeMachine, Massilly North America, and KULP Packaging offer innovative, high-quality machines designed for various production needs. These brands are known for their efficiency, speed, and customizable solutions.

Leading Manufacturers in the Capping Machine Industry

- iPharmachine

Located in China, iPharmachine is a global leader in the capping machine industry. With over 20 years of experience, they provide a wide range of solutions, from semi-automatic to fully automatic capping machines. Their machines are known for their high-speed capping, flexibility, and durability. - Massilly North America

Massilly specializes in vacuum capping systems for the food packaging industry. They offer machines that can reach speeds of up to 450 bottles per minute. Known for their customization options, Massilly’s machines are perfect for handling a variety of container shapes and sizes. - KULP Packaging

KULP Packaging from Turkey is renowned for its high-quality, long-lasting capping machines. Their equipment is known for its precision and innovative features, such as integrated cap lifters and stepper motor-driven capping heads. - Closure Systems International (CSI)

CSI, based in the USA, is another top manufacturer of capping machines, providing solutions for both small and large-scale production. Their machines are designed for screw capping and integrate seamlessly with filling lines for maximum efficiency. - Labemachine

Labemachine, based in China, is a prominent manufacturer specializing in a wide range of packaging and capping solutions. Known for its high-precision bottle capping machines, Labemachine provides innovative, customizable capping systems that ensure durability, high efficiency, and compatibility across various industries.

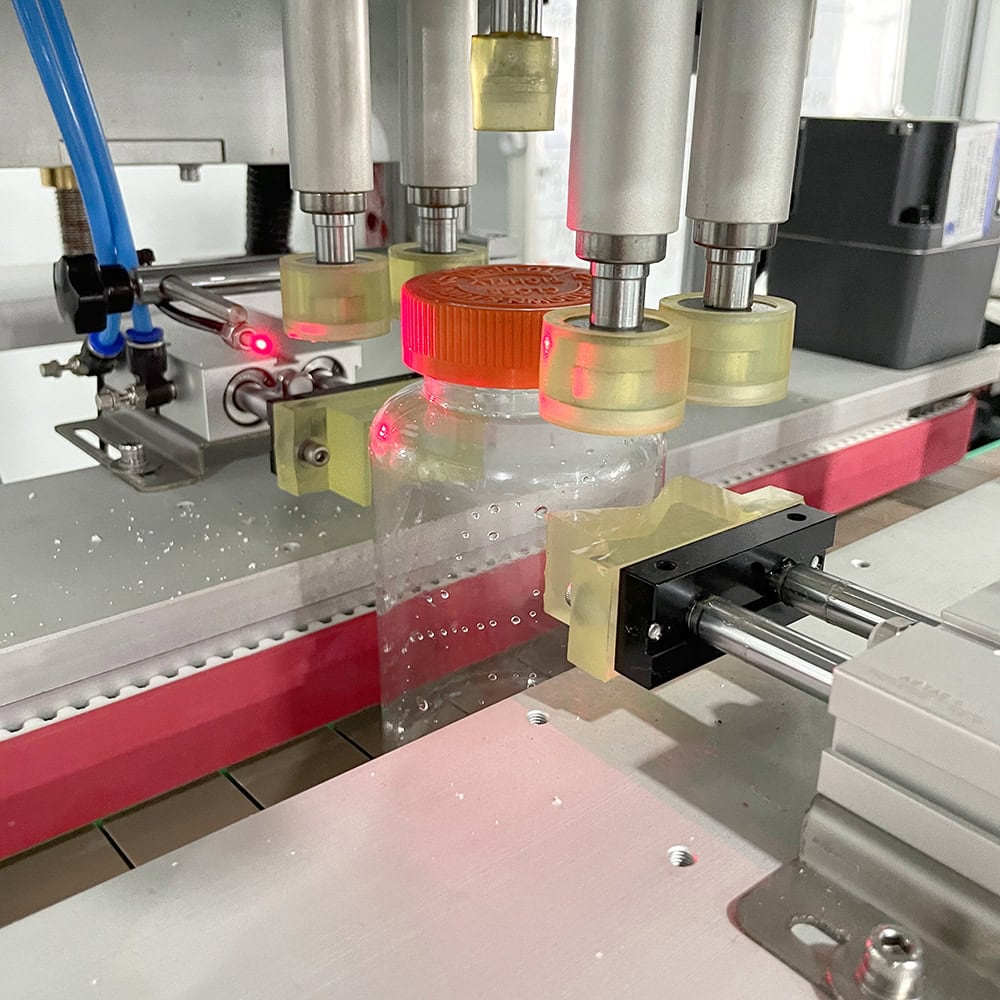

What Are the Types of Capping Machines Offered by Leading Manufacturers?

Capping machines come in various types, each suited to different production needs. Leading manufacturers offer solutions for multiple capping methods, including ROPP, crown, and screw capping.

Manufacturers offer a variety of capping machines, including manual, semi-automatic, and fully automatic machines, each tailored for specific types of caps and production volumes.

Types of Capping Machines

- Manual Capping Machines

Manual capping machines are simple, cost-effective solutions for small-scale operations. These machines are operated manually and are perfect for startups or low-volume production. - Semi-Automatic Capping Machines

Semi-automatic capping machines are more efficient than manual models. They automate the capping process while still requiring some human intervention. These machines are ideal for medium-scale operations. - Automatic Capping Machines

Fully automatic capping machines are designed for high-volume production. These machines can cap thousands of bottles per hour, reducing labor costs and increasing efficiency. - ROPP Capping Machines

ROPP (Roll-On Pilfer-Proof) capping machines are used for tamper-evident seals, primarily in the wine and pharmaceutical industries. These machines ensure secure closures that are difficult to open without visible damage.

What Are the Challenges When Choosing a Capping Machine Manufacturer?

Selecting the right capping machine manufacturer can be challenging. Key factors to consider include machine compatibility, cost, and customization needs.

Choosing the right manufacturer can be difficult, but understanding your production requirements and evaluating factors like compatibility, cost, and customization options can help make the decision easier.

Challenges in Choosing the Right Manufacturer

- Machine Compatibility

Ensuring that the capping machine integrates seamlessly with your existing production line is essential. Some manufacturers, like iPharmachine, offer machines that can easily be customized to fit specific production needs. - Cost vs. Quality

While high-quality machines are more expensive, they offer better long-term value through increased efficiency and durability. Balancing cost with quality is one of the biggest challenges in choosing the right machine. - Customization Needs

Some businesses require specific features, such as custom cap sizes or high-speed capabilities. Leading manufacturers provide tailored solutions that meet unique production needs, ensuring a perfect fit for your operations.

Conclusion

Choosing the best capping machine manufacturer depends on factors like product variety, technology, and after-sales support. Brands like iPharmachine, LabeMachine, Massilly North America, and KULP Packaging stand out for their innovation, speed, and high-quality solutions tailored to different industries. Whether you’re in need of a bottle capping machine or a packaging machine, these manufacturers are reliable partners for any business.