Securing palletized goods during transit is a challenge many businesses face, resulting in potential product damage and logistical setbacks. A pallet wrapping machine is a solution that enhances stability and safety, protecting products throughout the supply chain.

A pallet wrapping machine is an automated or semi-automated device that applies stretch film around palletized loads, securing items for safe storage and transportation. These machines improve packaging efficiency, protect goods, and reduce product damage.

Let’s explore how pallet wrapping machines work, their benefits, types, and how to choose the right one.

What is a Pallet Wrapping Machine?

A pallet wrapping machine is an essential piece of packaging equipment used to wrap stretch film around loaded pallets. It stabilizes products on the pallet, ensuring they remain secure and protected during transport or storage. This equipment is widely used in industries such as warehousing, manufacturing, and distribution, where the safe handling of bulk items is crucial.

Incorporating a pallet wrapping machine into your logistics process can also reduce costs by lowering the risk of product damage and improving loading efficiency. For businesses shipping delicate or heavy goods, pallet wrapping offers significant operational benefits.

How Does a Pallet Wrapping Machine Work?

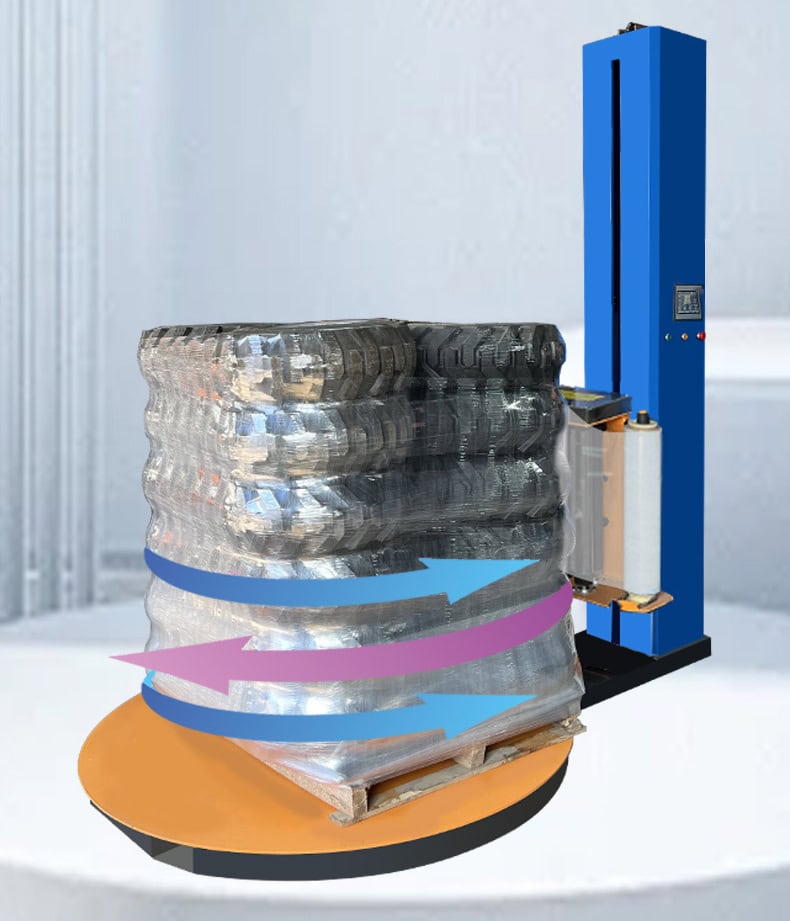

Pallet wrapping machines operate by rotating the pallet or a rotating arm around the pallet, layering stretch film tightly over the load. This action secures the items, creating a stable package that is easier to transport and store.

Film Stretching Mechanism

Pallet wrapping machines apply stretch film in a way that maximizes load stability while minimizing material usage. The film stretches as it wraps, ensuring a tight and secure fit. Advanced machines allow operators to adjust the tension and pre-stretch settings, further enhancing load security.

Key Functions of Pallet Wrapping Machines

- Load Security: By tightly wrapping items together, the machine prevents load shifting and minimizes the risk of accidents or damage.

- Protection from External Factors: Stretch film serves as a barrier against dust, moisture, and dirt, preserving the quality of goods.

- Efficient Packaging: Automating the wrapping process reduces manual labor and packaging time, making operations more efficient.

Types of Pallet Wrapping Machines

There are several types of pallet wrapping machines, each designed to meet specific needs. The right machine choice depends on factors like load size, frequency of use, and budget.

Turntable Wrappers

Ideal for small to medium-sized operations, turntable wrappers rotate the pallet while the film applicator remains stationary. This type is suitable for standard, lighter loads and offers reliable performance.

Rotary Arm Wrappers

For heavier or delicate loads that can’t be rotated, rotary arm wrappers keep the pallet stationary while a rotating arm applies the film. This type of machine is often found in facilities that handle high-volume, fragile items.

Robotic Wrappers

Robotic wrappers are portable machines that move around the pallet, applying film. These are highly flexible and useful in facilities where load positions vary or where mobility is a priority.

Ring Wrappers

Ring wrappers operate at high speeds and are commonly used in large, high-output facilities. The pallet passes through a ring, which rotates and applies the wrap at an efficient pace, making it ideal for operations with continuous packaging needs.

Automatic vs. Semi-Automatic Wrapping Machines

Automatic Machines

Automatic pallet wrapping machines are designed for high-volume operations, providing fully automated wrapping cycles. Equipped with sensors and preset programs, these machines require minimal operator involvement, improving throughput and consistency.

Semi-Automatic Machines

Semi-automatic machines are best for medium production levels. These require an operator to start the process, but the wrapping itself is automated, offering a balance between manual control and efficiency.

Benefits of Using a Pallet Wrapping Machine

- Time and Labor Savings: Automated wrapping significantly reduces the time and effort required to secure pallets, freeing up workers for other tasks.

- Consistent Wrapping Quality: With adjustable tension and pre-stretch settings, these machines ensure a uniform wrapping quality that minimizes the risk of load shifting.

- Cost-Effectiveness: Using a wrapping machine reduces film waste, as the machine optimizes film usage and saves on labor costs.

For businesses managing high volumes of packaging, a pallet wrapping machine can streamline operations and reduce costs. Additionally, a packaging machine for products such as bottles or other items can work alongside a pallet wrapper to ensure each stage of the packaging process is automated and efficient.

Key Features to Consider When Choosing a Machine

Load Capacity

When choosing a pallet wrapper, consider the maximum load weight and size. Heavier loads typically require a rotary arm or robotic wrapper for safe handling.

Film Compatibility

Machines are often optimized for specific types of stretch film. Verifying compatibility can help reduce wear on the machine and ensure optimal film application.

Speed and Efficiency

Facilities with high production volumes should consider high-speed models to keep up with demand. Machines with adjustable speeds allow flexibility for different load types.

Customization Options

Many machines come with programmable settings and optional sensors, allowing customization for different wrapping needs. Advanced models may include digital interfaces for easy operation and settings adjustments.

Common Industries Using Pallet Wrapping Machines

Pallet wrapping machines are essential in various industries:

- Warehousing and Distribution: Essential for securing bulk goods in transport.

- Manufacturing: Used to wrap pallets containing raw materials or finished products.

- E-commerce and Retail: Keeps goods secure and organized in delivery networks.

Common Questions on Pallet Wrapping

How Long Does It Take to Wrap a Pallet?

The wrapping time depends on the machine type and load size, ranging from 30 seconds with high-speed models to several minutes for manual setups.

Is Pallet Wrap Waterproof?

Stretch film provides waterproof coverage to a certain extent, protecting items from moisture but not suitable for prolonged exposure to water.

Can You Reuse Pallet Wrap?

Pallet wrap is generally single-use, as reusing it could compromise the load’s stability. However, efficient film usage can lower the material costs per pallet.

Maintenance and Safety Tips

Routine Maintenance

Regular maintenance, such as lubricating parts and cleaning sensors, ensures the machine operates smoothly. Check for wear on moving parts and replace components as needed.

Operator Training

Proper training for operators minimizes errors and ensures safe operation, particularly with high-speed or automatic machines. Some machines include emergency stop features and protective coverings for added safety.

Safety Features

Most machines are equipped with safety features such as emergency stops and guards. Ensuring these are in place and functional is critical for workplace safety.

Conclusion

A pallet wrapping machine enhances the efficiency, safety, and stability of palletized goods, making it a valuable asset for businesses involved in shipping and warehousing. It’s an investment that not only reduces product damage but also streamlines operations. Adding complementary equipment, like a labeling machine, further optimizes the packaging process, ensuring each load is securely prepared for transport.