Downtime due to malfunctioning packaging machines can cause significant delays and financial losses for any manufacturing company. Understanding the various parts of a packaging machine can prevent these interruptions and ensure smooth operations.

A typical packaging machine consists of several key parts, including the feeding mechanism, sealing unit, and control systems. Each component works together to ensure efficient, high-speed packaging with minimal error.

Keep reading to explore these essential components in detail.

Feeding Mechanism

The feeding mechanism is one of the most important parts of a packaging machine. It ensures that the products move into the packaging process in a smooth and orderly manner.

- Product Feeders: These systems place products in the correct position for packaging. Common types include belt conveyors and robotic arms.

- Importance: A well-functioning feeding mechanism prevents delays and blockages, helping the entire production line to run efficiently. Labeling Machine applications often depend on the reliability of the feeding mechanism.

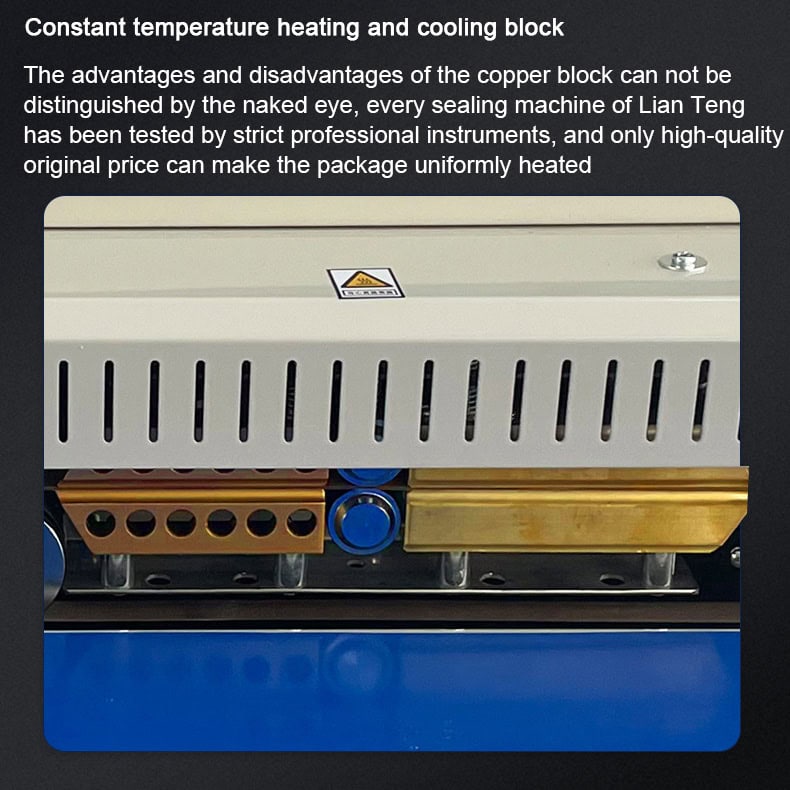

Sealing Unit

The sealing unit is responsible for securely closing packages. This step is crucial to ensuring that products are protected from contamination and damage during transport.

- Heat Sealers: These machines use heat to bond materials such as plastic films together. This creates a strong, tamper-evident seal.

- Adhesive Sealers: In some packaging systems, glue or other adhesives are used to secure the packages.

Labeling Mechanism

Labeling mechanisms add necessary information to each package, such as barcodes or expiration dates. They also help with branding and regulatory compliance.

- Sensors: Sensors detect the product’s position and ensure the label is applied accurately.

- Label Applicators: These machines place labels on packages in the correct orientation.

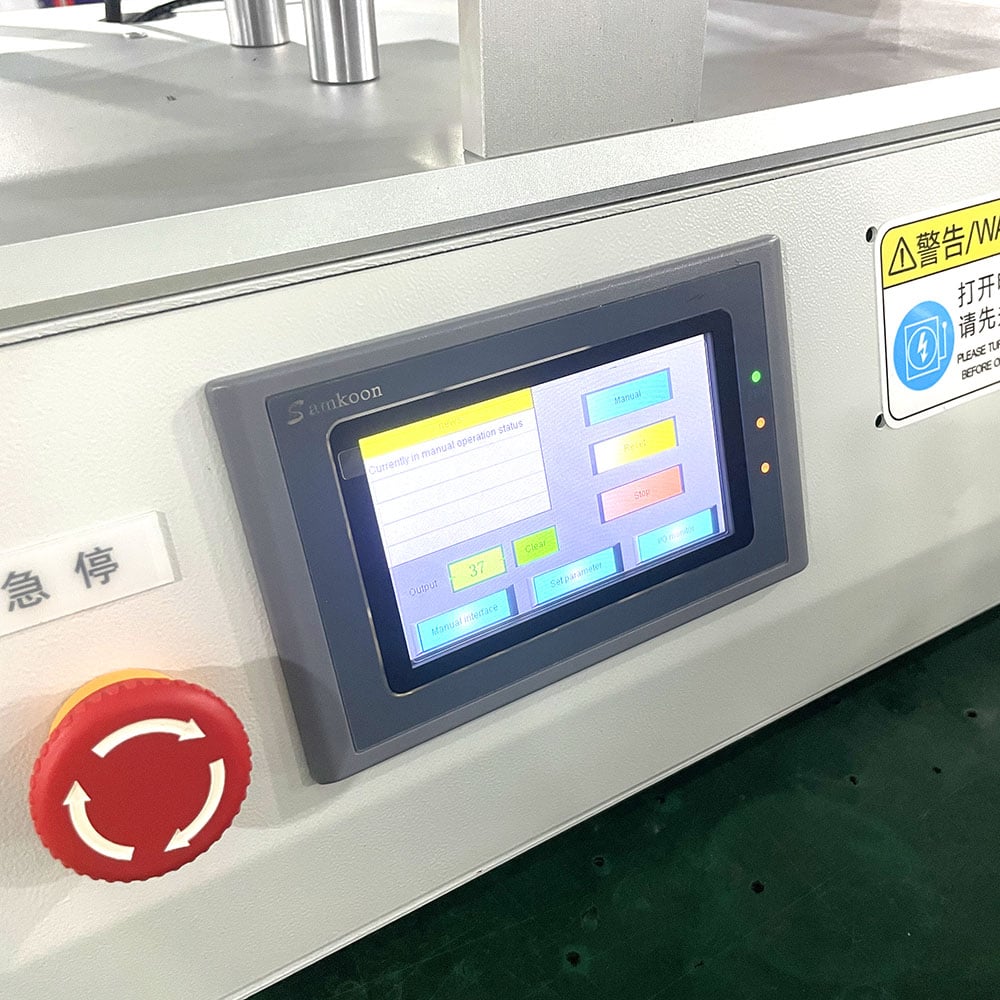

Control System (PLC)

The control system, typically managed by a Programmable Logic Controller (PLC), coordinates all of the machine’s actions, including product feeding, sealing, and labeling.

- Programmable Interface: Operators can adjust machine settings and monitor operations through an easy-to-use touch-screen interface.

- Automation: The PLC automates processes, allowing for efficient, high-speed packaging.

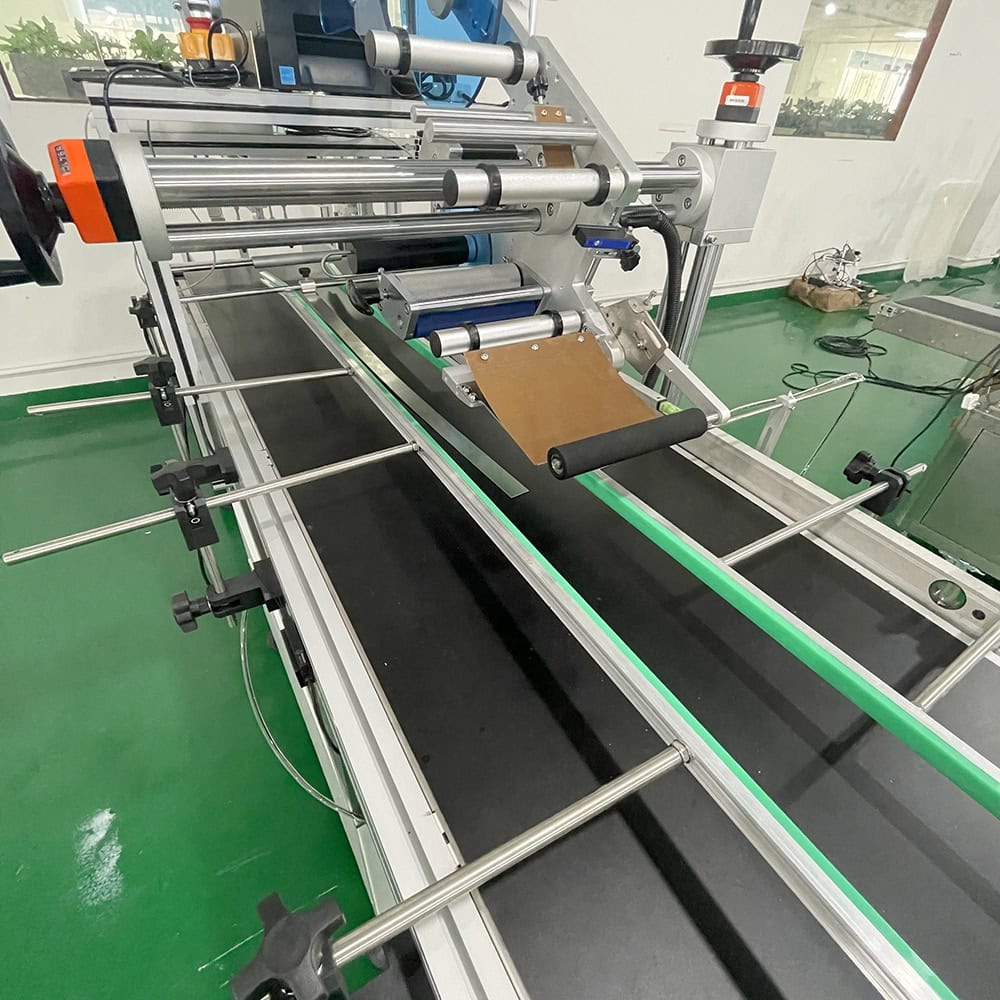

Film Unwinding Unit

For machines that handle flexible packaging, the film unwinding unit ensures that the packaging material (such as plastic film) is dispensed smoothly and with the correct tension.

- Film Rollers: These rollers maintain tension in the film to prevent wrinkles and ensure a consistent sealing process.

- Importance: Maintaining proper film tension ensures the packaging is sealed properly, preventing leaks or weak points.

Conveyor Belt

Conveyor belts transport products through each phase of the packaging process. Their speed and consistency are essential for the overall flow of production.

- Material and Speed: Conveyor belts are typically made from rubber or plastic-coated materials, and their speed can be adjusted according to production needs.

- Customization: Conveyor belts are adjustable in speed and can be configured for different packaging styles, including those used in Bottle Filling Machine systems.

Forming Unit

Forming units are essential in machines that handle flexible materials, such as bags or pouches. These units shape the material into a packaging form before it is filled.

- Shaping Mechanisms: The machine forms the package, such as a bag, before filling it with product.

- Importance: A properly formed package ensures uniform appearance and seals properly during the packaging process.

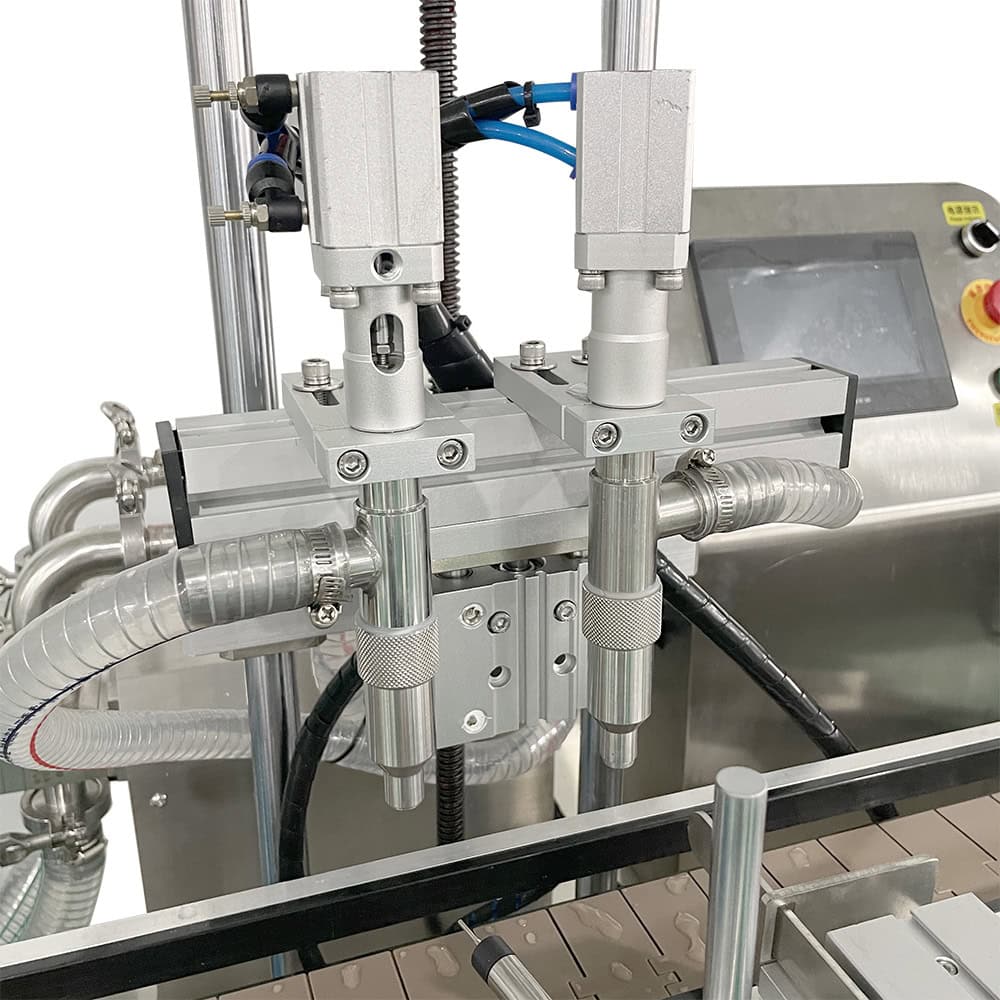

Filling Unit

The filling unit is where the actual product, whether solid, liquid, or powder, is placed into the package. Different types of filling mechanisms are used depending on the nature of the product.

- Volumetric Fillers: These are used for liquids, allowing precise volume control to prevent overfilling.

- Auger Fillers: Often used in powder filling machines, they work by rotating a screw to dispense a consistent amount of powder.

Sensors

Various sensors are used throughout the machine to monitor different functions such as product positioning, packaging integrity, and the labeling process.

- Photoelectric Sensors: These sensors detect when a product is in the correct position for labeling or sealing.

- Proximity Sensors: These sensors help detect objects without making physical contact.

Maintenance and Troubleshooting Systems

Many packaging machines come with built-in systems that assist with maintenance and troubleshooting, such as automatic lubrication systems and diagnostic software.

- Lubrication Systems: These systems keep moving parts running smoothly by automatically applying oil or grease.

- Error Detection: Machines equipped with error detection systems can alert operators when a part is malfunctioning, preventing breakdowns.

Conclusion

The key parts of a packaging machine work together to automate the packaging process efficiently. Understanding these components, from feeding mechanisms to control systems, can help in ensuring smooth operations and reducing downtime.