Struggling with damaged packages in transit can lead to returns and unhappy customers. Using the wrong tape might mean that your cartons are not secure, resulting in damaged products and increased shipping costs. Carton sealing tape is what makes your packages safe.

Carton sealing tape is used to close and seal boxes and packages. It provides strength, protection, and tamper evidence making it essential for shipping, warehousing, and long-term storage.

Find out how carton sealing tape plays a critical role in your packaging security and efficiency.

Primary Function of Carton Sealing Tape

The main reason you use carton sealing tape is to close and secure your boxes so your stuff doesn’t fall out in transit. Whether you are shipping stuff across the country or moving stuff in a warehouse, you don’t want your boxes to open or lose their integrity as they are being transported. When you maintain the structural integrity of the carton, you protect the contents from damage, contamination, or loss.

It also helps you label your boxes by keeping your address label or shipping instructions stuck to the box. You can get it clear or opaque depending on your needs.

Material and Durability

Most carton sealing tapes are made from durable materials such as polypropylene or polyester film backing. These materials are known for their strength, flexibility, and tear resistance, making the tape highly effective in withstanding the rigors of shipping. The adhesives used in carton sealing tape are pressure-sensitive, which means they bond firmly to surfaces with minimal application force.

The tape’s durability ensures that it performs well under different environmental conditions. Whether exposed to moisture, temperature fluctuations, or handling stress, carton sealing tape keeps packages secure during transit or storage.

Types of Carton Sealing Tape

There are several types of carton sealing tapes designed to meet various packaging needs:

- Pressure-sensitive tape: This is the most commonly used tape in packaging. It is easily applied using pressure, creating a strong bond without needing additional tools or heat. Pressure-sensitive tape is ideal for general-purpose packaging.

- Water-activated tape (gummed tape): This type of tape is activated by water and bonds strongly with the carton, creating a tamper-evident seal. It is often used for heavier packages or in cases where extra security is required.

Each type of tape offers unique advantages depending on the type of packaging and security level needed.

Applications in Shipping and Warehousing

Carton sealing tapes play an indispensable role in the shipping and warehousing industries. Companies rely on these tapes to protect the products they send out, ensuring that they reach customers intact. From small businesses to large distribution centers, the secure sealing of cartons prevents product loss and damage, reducing costly returns and customer complaints.

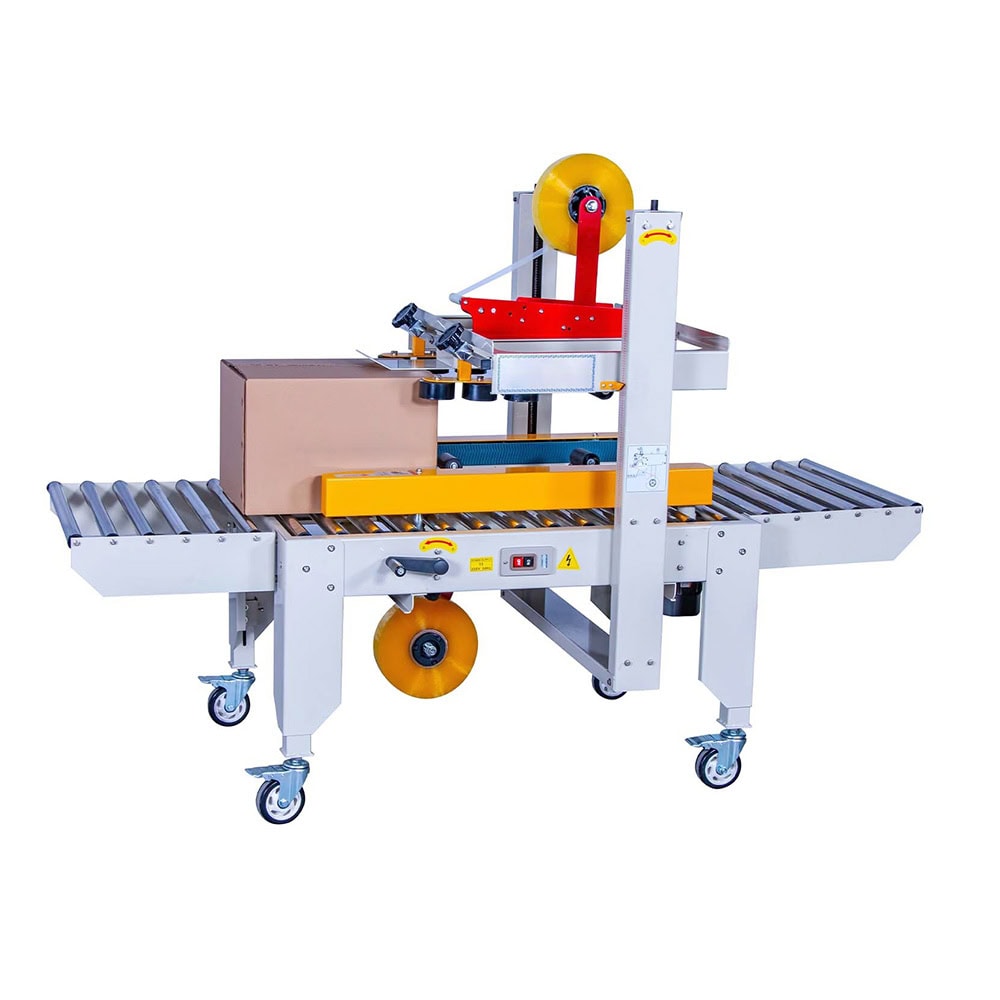

In warehousing, carton sealing tape is used not only for outgoing shipments but also for securing inventory during storage. Properly sealed cartons protect goods from dust, moisture, and other environmental factors. It can also be used in production lines in conjunction with labeling machines.

How to Apply Carton Sealing Tape

Applying carton sealing tape is straightforward but requires attention to detail to ensure maximum effectiveness. Start by positioning the tape at the edge of the seam where the carton flaps meet. Slowly apply the tape while pressing down to ensure smooth adhesion. A tape dispenser can simplify this process, allowing for faster and more consistent application.

For added security, apply two strips of tape – one along the central seam and one on either side of it. This double-taping method strengthens the carton, especially when dealing with heavy or bulky items.

Benefits of Using Carton Sealing Tape

- Tamper resistance: Carton sealing tape provides a secure closure, making it evident if someone has tried to open the package.

- Water and dust protection: High-quality sealing tape creates a barrier that protects the contents of the carton from external elements such as water, dust, and dirt.

- Ease of use: With tape dispensers and hand-held tools, carton sealing tape is quick and easy to apply, making packaging processes more efficient.

Comparison Between Water-Activated Tape and Carton Sealing Tape

Water-activated tape, though stronger, requires additional equipment or a water-based activator. This makes it more time-consuming to apply but offers better security, especially for heavier packages. In contrast, carton sealing tape is quicker and more convenient to use, making it ideal for everyday applications in shipping and warehousing.

When choosing between the two, businesses should consider the level of security needed and the speed of application required.

Common Uses Across Industries

Carton sealing tape is widely used across various industries such as e-commerce, retail, electronics, and food packaging. Its versatility allows it to be adapted to different types of packaging requirements, from light parcels to large, heavy boxes.

E-commerce companies, in particular, rely heavily on carton sealing tape to secure packages efficiently, ensuring timely deliveries. Similarly, food and beverage companies use sealing tape to preserve the hygiene and safety of their products during transport.

Sustainability and Environmental Considerations

As businesses strive to reduce their environmental footprint, many are shifting to eco-friendly carton sealing tapes. These tapes are made from recyclable or biodegradable materials, ensuring they meet sustainability goals without sacrificing performance.

Companies looking to improve their packaging’s environmental impact are opting for tapes that are not only durable but also recyclable, reducing waste in the supply chain.

Best Practices for Effective Use

To make the most out of carton sealing tape, it’s essential to choose the correct tape thickness and material based on the weight of the carton. For heavy-duty packaging, thicker tape with a strong adhesive is recommended. Always apply the tape evenly and ensure it’s properly adhered to all edges to prevent gaps or wrinkles.

Proper storage of the tape is also important. Keep the tape in a dry and cool environment to preserve its adhesive properties for longer use.

Conclusion

Carton sealing tape is essential for safe, reliable packaging in various industries, providing durability, security, and ease of application.