The Automatic Bottle Capping Machine offers high-speed, precise capping for bottles with cap diameters of 18-65mm. With adjustable bottle height and a robust PLC control system, it ensures secure and efficient operation across various industries.

| Weight | 140 kg |

|---|---|

| Dimensions | 2000 × 600 × 1420 mm |

| Cap Diameter Range | 18-65mm |

| Capping Speed | 30~350mm |

| Air Consumption | 10L/min |

| Working Pressure | 0.4-0.6MPa |

| Power | 1.2KW |

| Voltage | AC220V/50Hz |

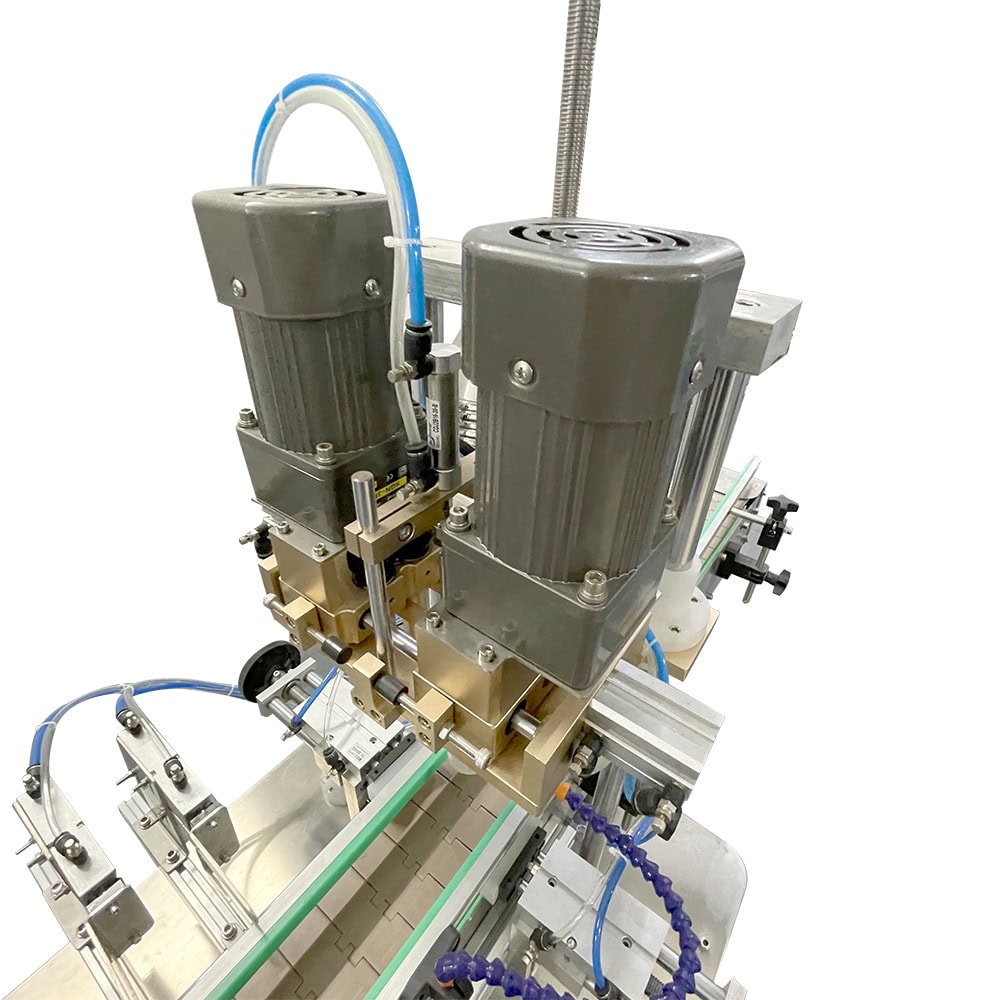

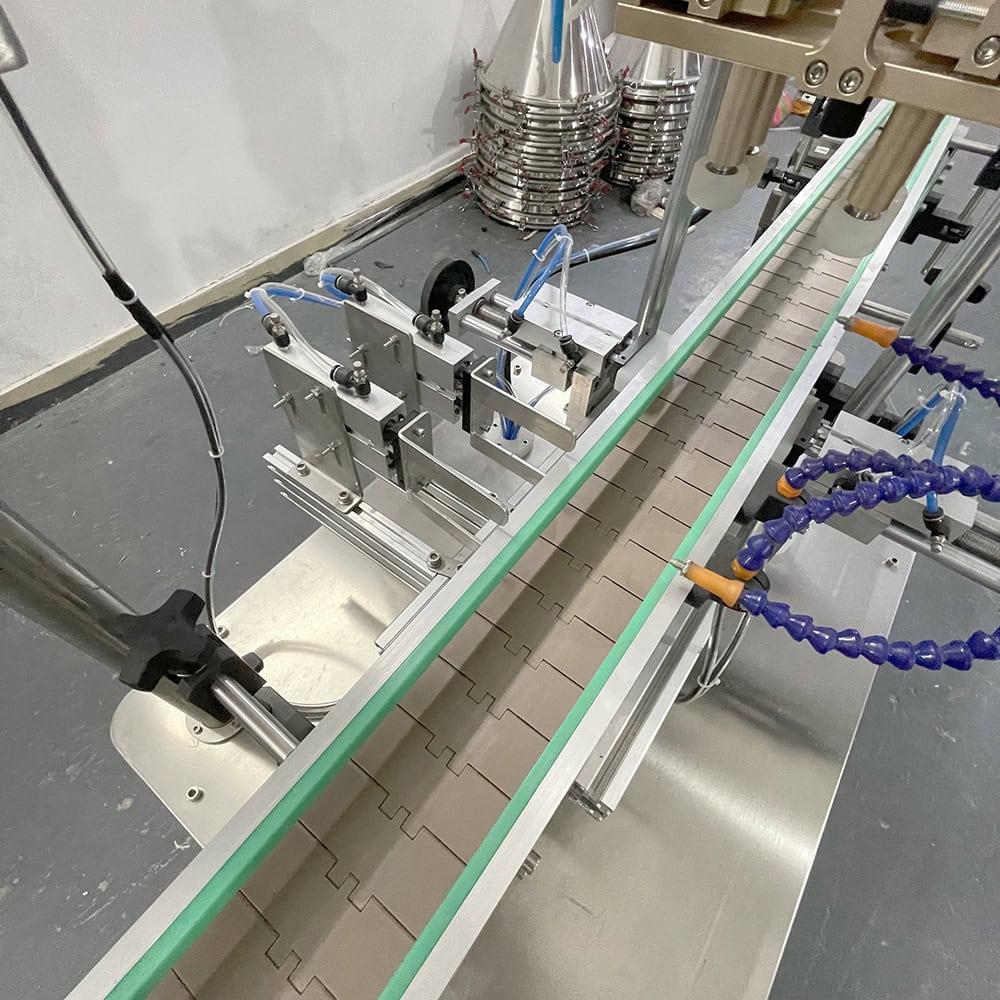

The Automatic Bottle Capping Machine is a versatile and highly efficient solution designed for automatic capping of bottles with cap diameters ranging from 18mm to 65mm. This machine is ideal for a wide variety of industries, accommodating bottles of various heights from 30mm to 350mm. Equipped with a robust PLC control system, the machine allows for precise adjustment of parameters to meet specific production requirements. The capping mechanism utilizes four rubberized wheels that simultaneously grip and rotate the cap, ensuring it is tightly secured to the bottle.

|

Weight:

|

140 KG

|

|

Dimensions:

|

2000 x 600 x 1420mm

|

|

Cap Diameter Range:

|

18-65mm

|

|

Capping Speed:

|

30-350mm

|

|

Air Consumption:

|

10L/min

|

|

Working Pressure:

|

0.4-0.6MPa

|

|

Power:

|

1.2KW

|

|

Voltage:

|

AC220V 50Hz

|

The Automatic Bottle Capping Machine is ideal for use across a variety of industries that require precise and efficient capping solutions. Key applications include:

LabeMachine is a specialized manufacturer of labeling machines and complementary equipment. Our main products include wire labeling machines, bottle labeling machines, flat labeling machines, packaging machines, and filling machines. We are committed to providing high-quality, reliable solutions for all your labeling and packaging needs. more+

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more