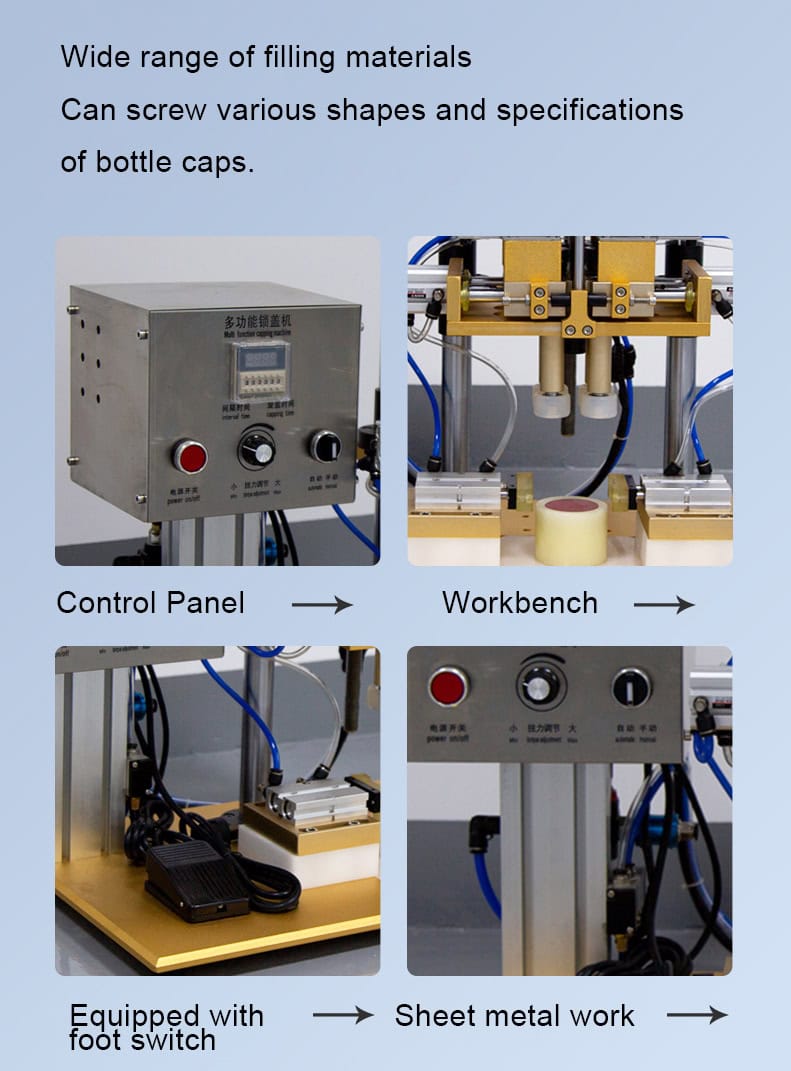

The LBM-SXY-1203 Multi-function Bottle Capping Machine is designed for capping various bottles in industries such as cosmetics, pharmaceuticals, and food. It features a compact design, supports different cap sizes, and operates in both manual and automatic modes. With a user-friendly control panel, it allows for easy adjustments of capping time, frequency, and pressure. This machine ensures efficient, smooth operation with minimal noise and energy consumption, making it ideal for streamlined production.

| Weight | 31 kg |

|---|---|

| Dimensions | 500 × 350 × 600 mm |

| Model | LBM-SXY-1203 |

| Production Efficiency | 30-50 bottles/min |

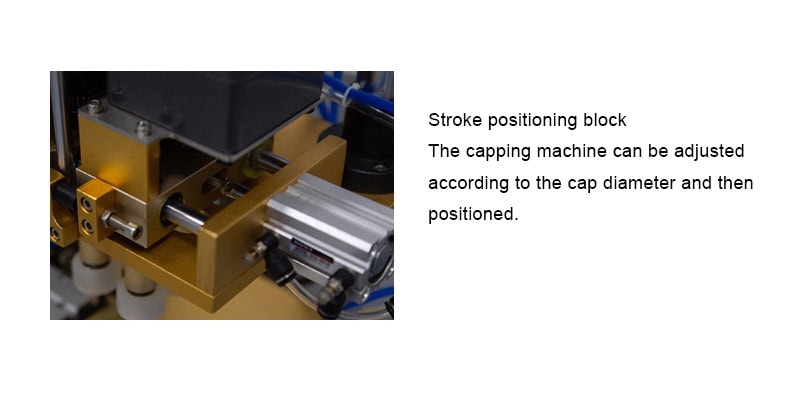

| Applicable Cap Diameter | 12-60mm (Customizable) |

| Applicable Bottle Height | 300mm (Customizable) |

| Cap Types Supported | Various shapes and specifications |

| Operating Air Pressure | 0.2-0.4 MPa |

The LBM-SXY-1203 Multi-function Bottle Capping Machine is a versatile and efficient solution for sealing bottles in various industries, including cosmetics, pharmaceuticals, chemicals, and food products. This machine is designed to handle a wide range of bottle cap types and sizes, making it suitable for different packaging needs.

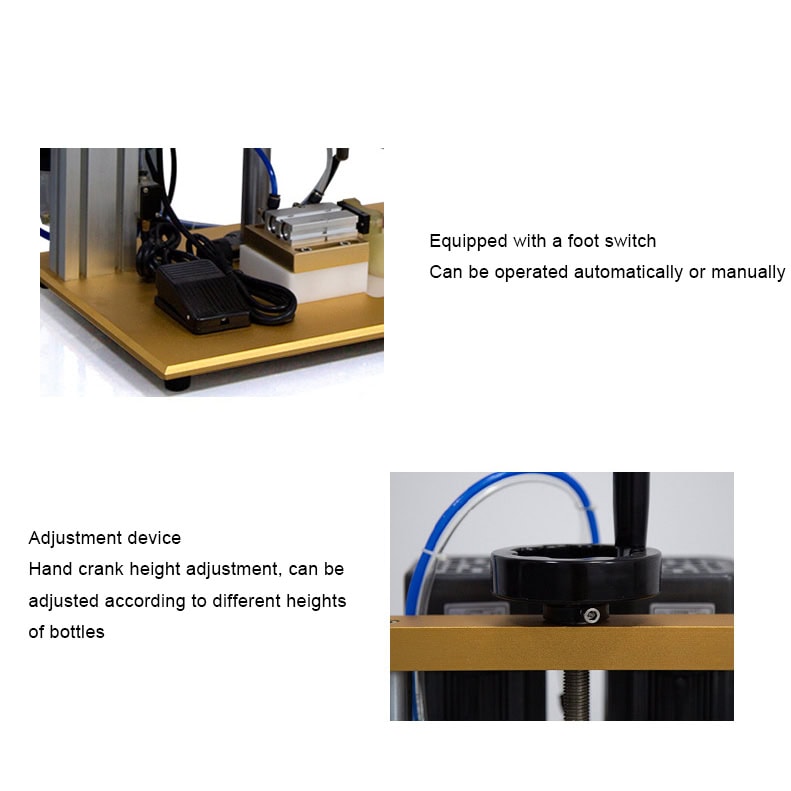

With both automatic and manual modes, the machine offers flexibility in operation, providing ease of use and high efficiency for production lines. Its compact design, low noise, and low energy consumption make it an ideal choice for manufacturers looking to streamline their capping processes.

| Model | LBM-SXY-1203 |

|---|---|

| Applicable Bottle Height | 300mm (Customizable) |

| Applicable Cap Diameter | 12-60mm (Customizable) |

| Production Efficiency | 30-50 bottles/min |

| Operating Air Pressure | 0.2-0.4 MPa |

| Dimensions | 50*35*60 cm |

| Weight | 31 kg |

| Operation Modes | Automatic/Manual (Foot pedal for manual mode, automatic mode via switch) |

| Motor Power | 60W |

| Voltage | 220V (Customizable) |

| Cap Types Supported | Various shapes and specifications |

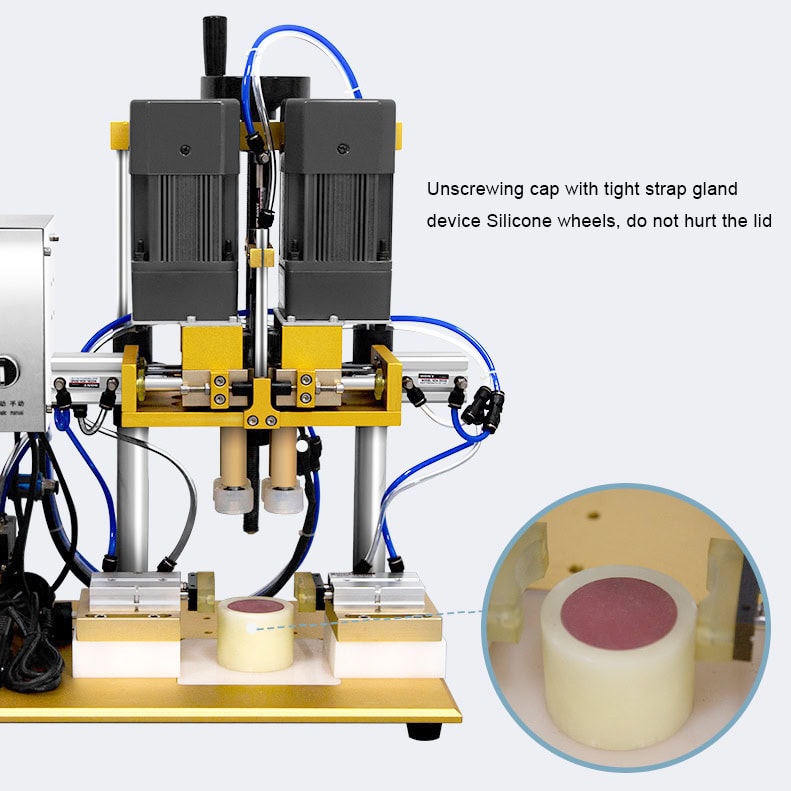

The LBM-SXY-1203 Multi-function Bottle Capping Machine is ideal for industries such as daily chemical products, pharmaceuticals, chemicals, and food processing. It is perfect for capping various types of bottles, including spray nozzles, aluminum caps, plastic round bottle caps, and duckbill caps. The machine utilizes both electrical and pneumatic controls, ensuring high stability and reliability. With adjustable capping force and the ability to handle different shapes and sizes of caps, this machine is easy to use and ensures a tight, secure fit for every bottle, making it a valuable addition to any production line.

LabeMachine is a specialized manufacturer of labeling machines and complementary equipment. Our main products include wire labeling machines, bottle labeling machines, flat labeling machines, packaging machines, and filling machines. We are committed to providing high-quality, reliable solutions for all your labeling and packaging needs. more+

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more