Labeling plays a critical role in product identification, branding, and compliance. For products like cartridges, precise labeling is essential to ensure accuracy and maintain production efficiency. Choosing the right labeling machine for cartridges can be a complex decision, especially when considering the different types of machines available.

Cartridge labeling machines can refer to either industrial-grade equipment designed for high-volume labeling of small cylindrical products or compact handheld devices used for quick coding and marking. Understanding the differences between these machines is key to selecting the right solution for your needs.

Let’s explore the two main types of cartridge labeling machines, their applications, and how to determine which is the best fit for your business.

Industrial Cartridge Labeling Machines

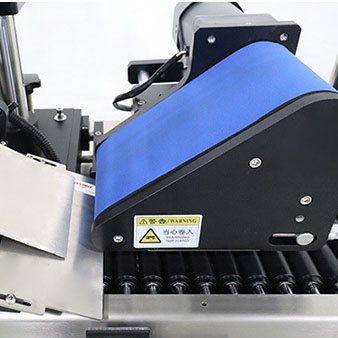

Industrial cartridge labeling machines are designed for high-speed, precise labeling of small, often cylindrical products such as ink cartridges, filters, and medical vials. These machines are typically integrated into production lines, where they automate the labeling process, applying labels with accuracy and consistency.

These machines are essential in industries where labeling accuracy is paramount. For example, in the pharmaceutical industry, where incorrect labeling could have serious consequences, these machines ensure that each product is labeled correctly every time. They are built to handle high volumes, operating continuously to meet production demands without sacrificing precision.

Additionally, industrial cartridge labeling machines often come equipped with advanced features like vision systems that verify label placement, and sensors that adjust the application process based on the product’s shape and size. This level of automation reduces the need for manual intervention, lowers the risk of human error, and ensures that every product meets the required standards.

Handheld Cartridge Labeling Machines

On the other end of the spectrum, handheld cartridge labeling machines offer flexibility and portability for smaller-scale labeling needs. These devices are compact, easy to use, and ideal for businesses that require a versatile tool for on-the-spot labeling. Unlike industrial machines, which are stationary and designed for high-volume output, handheld machines are portable and can be used across various locations within a facility.

Handheld cartridge labeling machines are perfect for tasks like applying date codes, QR codes, or simple text labels on products. They are particularly useful in environments where products are labeled on-demand, such as in warehouses or smaller manufacturing setups. The ability to quickly and accurately mark products with necessary information makes these devices invaluable in maintaining operational efficiency.

One of the key advantages of handheld machines is their ease of use. They require minimal training, can be operated by a single person, and are designed to be intuitive. This makes them a cost-effective solution for businesses that do not need the full capabilities of an industrial labeling machine but still require accurate and reliable labeling.

Choosing Between Industrial and Handheld Solutions

The decision between an industrial cartridge labeling machine and a handheld device depends largely on your production needs and the scale of your operations. For large-scale manufacturers dealing with high volumes of products, an industrial labeling machine is the obvious choice. These machines offer speed, precision, and the ability to handle complex labeling tasks with minimal human intervention.

For smaller businesses, or those with more varied labeling needs, a handheld cartridge labeling machine may be more appropriate. These machines offer the flexibility to label different products quickly and efficiently, without the need for extensive setup or space.

It’s also worth considering the long-term cost implications. While industrial machines represent a significant upfront investment, they typically offer greater efficiency and lower operating costs over time. Handheld machines, on the other hand, are less expensive initially but may require more manual effort, which could impact productivity in larger operations.

Key Features to Look for in a Cartridge Labeling Machine

When selecting a cartridge labeling machine, there are several key features to consider. For industrial machines, look for models that offer high-speed labeling, accurate placement, and the ability to handle various product sizes. Advanced features like automated label verification and error detection can also be critical in ensuring product quality.

For handheld devices, portability, ease of use, and versatility are the primary considerations. The machine should be lightweight, easy to operate, and capable of printing or applying a range of label types. Battery life and print quality are also important factors, especially if the machine will be used frequently or in different locations.

No matter which type of machine you choose, it’s important to ensure that it meets your specific needs and can integrate seamlessly into your existing workflow.

The Importance of Maintenance and Support

Both industrial and handheld cartridge labeling machines require regular maintenance to ensure optimal performance. For industrial machines, this often involves routine checks of the mechanical components, sensors, and labeling systems to prevent downtime and extend the machine’s lifespan.

Handheld machines, while simpler in design, still require care to maintain their effectiveness. Regularly replacing print cartridges, keeping the device clean, and ensuring it’s stored properly will help prolong its usability and ensure consistent labeling quality.

Additionally, consider the level of support offered by the manufacturer. Good after-sales service, including access to spare parts and technical assistance, can make a significant difference in the long-term value of your investment.

Conclusion: Finding the Right Cartridge Labeling Solution

Choosing the right cartridge labeling machine depends on understanding your production needs and the specific requirements of your products. Whether you need the high-speed precision of an industrial machine or the flexibility of a handheld device, selecting the right tool will enhance your labeling process and improve overall efficiency. Invest wisely to ensure that your labeling operations meet the highest standards of quality and consistency.