The Dual-Sided Round Bottle Labeler Machine labels the front and back of round bottles simultaneously. Suitable for food, cosmetics, pharmaceuticals, and chemicals.

| Weight | 18 kg |

|---|---|

| Dimensions | 1950 × 1200 × 1530 mm |

| Labeling Accuracy | ±1 mm |

| Labeling Speed | 25~55 pcs/min |

| Product Size | Diameter 25-90mm (customizable) |

| Label Size | Width: 20-285mm(customizable) |

| Power Supply | 220V/50HZ(modifiable) |

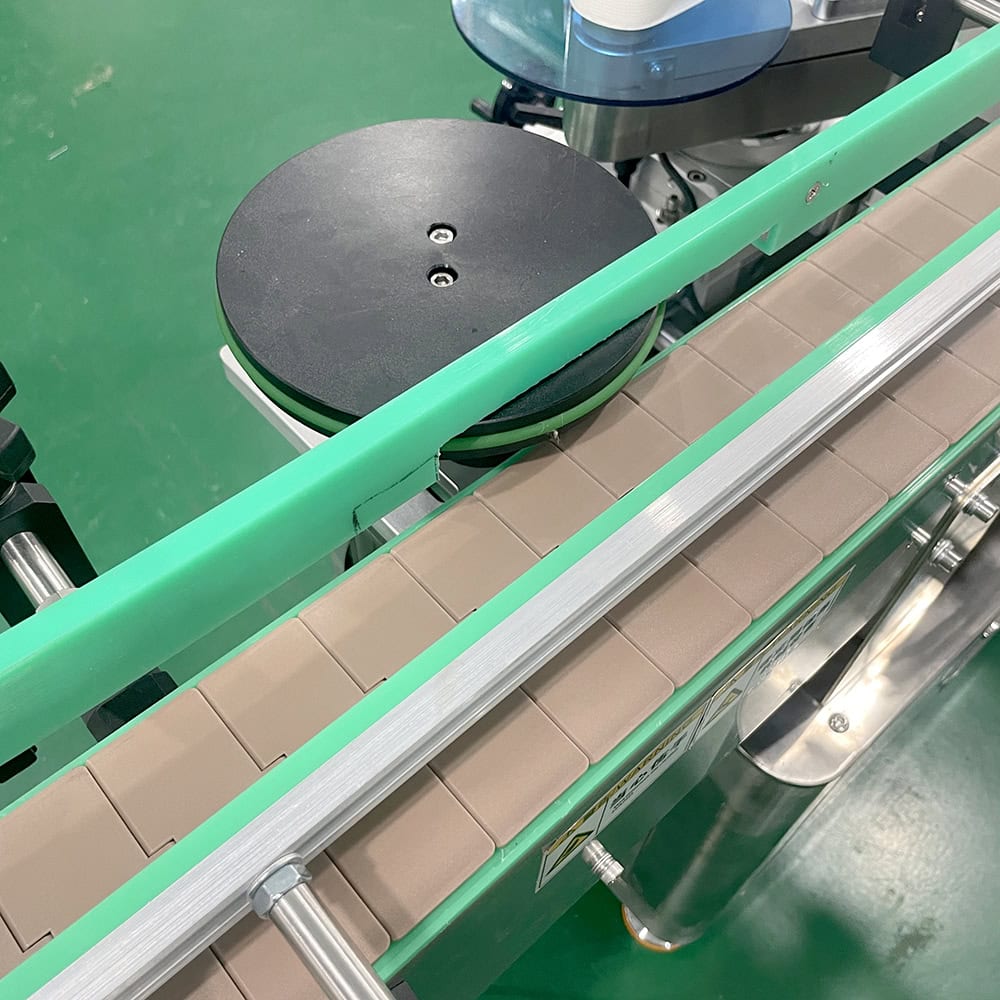

Dual-Sided Round Bottle Labeler Machine is specifically designed for efficiently applying two labels simultaneously to the front and back of round bottles. This machine is ideal for various industries, including food and beverage, cosmetics, pharmaceuticals, and chemicals. Its precise labeling system ensures consistent application, enhancing your production efficiency.

Applies labels to both the front and back of round bottles simultaneously.

Speeds up the labeling process, making it suitable for small to medium-scale production.

Compatible with various bottle sizes and materials, including glass and plastic.

Easy to set up and operate, with minimal training required.

Ensures precise and consistent label positioning.

Perfect for labeling bottles of juices, sauces, dressings, and other beverages. The dual-sided labeling provides a professional and polished look, enhancing brand visibility and appeal on store shelves.

Ideal for round bottles used for lotions, shampoos, conditioners, and other beauty products. The machine ensures that branding and product information are clearly displayed, meeting industry standards for packaging aesthetics and compliance.

Essential for labeling medicinal bottles, including syrups, solutions, and vitamins. Accurate dual-sided labeling ensures that important information, such as dosage instructions and ingredients, is prominently displayed, adhering to regulatory requirements.

Suitable for labeling bottles containing various chemicals, cleaning solutions, and industrial liquids. The dual-sided labels can include safety warnings and usage instructions, ensuring user safety and compliance with industry regulations.

This machine is particularly beneficial for small and medium-sized businesses looking to scale up their production capabilities while maintaining high labeling accuracy and efficiency. It supports brand growth by providing professional labeling solutions at a cost-effective price.

Barcode Printer, Ribbon Printer, Transparent Label Sensor, Bottle Unscrambler

If you are interested in our Dual-Sided Round Bottle Labeler Machine or need more information, please feel free to contact us. We look forward to providing you with high-quality products and services.

LabeMachine is a specialized manufacturer of labeling machines and complementary equipment. Our main products include wire labeling machines, bottle labeling machines, flat labeling machines, packaging machines, and filling machines. We are committed to providing high-quality, reliable solutions for all your labeling and packaging needs. more+

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more