The CCD Camera Visual Flat Labeling Machine is designed for high-precision label application on specific product locations. Ideal for the die-cutting, 3C, and SMT industries, it ensures accurate labeling for a variety of products.

| Weight | 200 kg |

|---|---|

| Dimensions | 1300 × 800 × 1700 mm |

| Labeling Accuracy | ±0.1mm |

| Labeling Speed | 15~25 pcs/min |

| Product Size | 100~140mm; T: 0.4~30mm |

| Label Size | 60 *60mm; T: 0.05~0.5mm |

| CCD Model: | Upper camera: 5MP, 3072×2048 |

The CCD Camera Visual Flat Labeling Machine is engineered for precision label application on specified product locations using a sophisticated CCD camera system. This advanced system captures and locates the exact position on the product for label placement, ensuring high accuracy. It is widely used in various industries such as electronics, pharmaceuticals, food, beverages, healthcare, daily chemicals, light industry, agricultural products, tobacco, hardware, seafood, and logistics. This machine is ideal for enhancing production efficiency and achieving automated, less manpower-dependent operations.

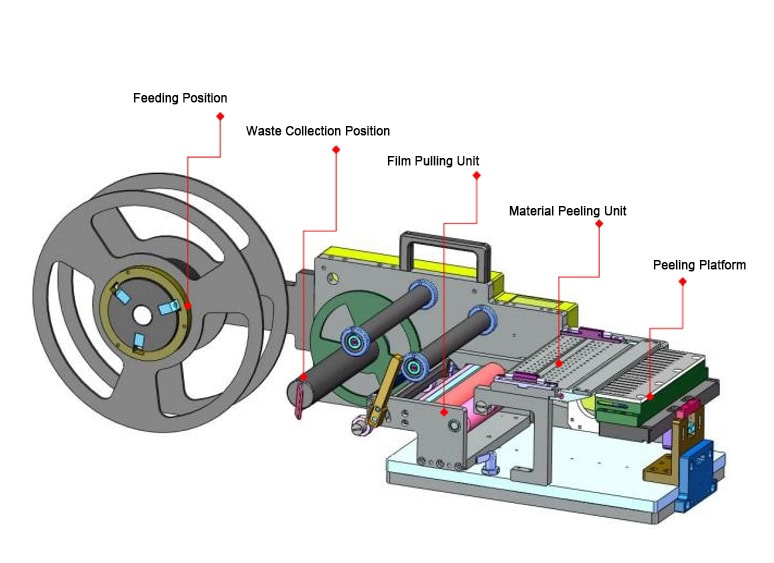

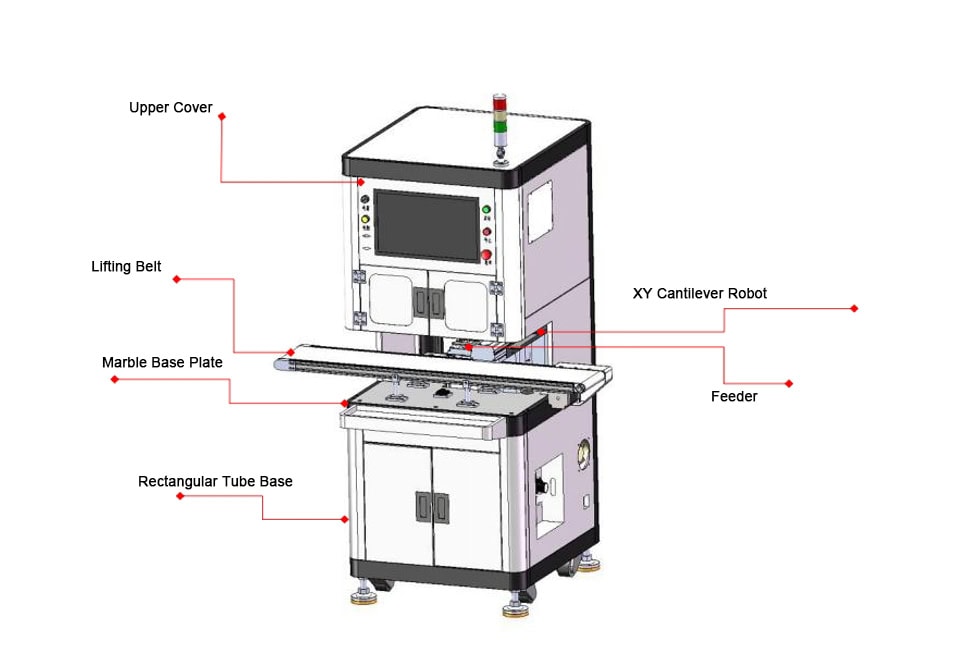

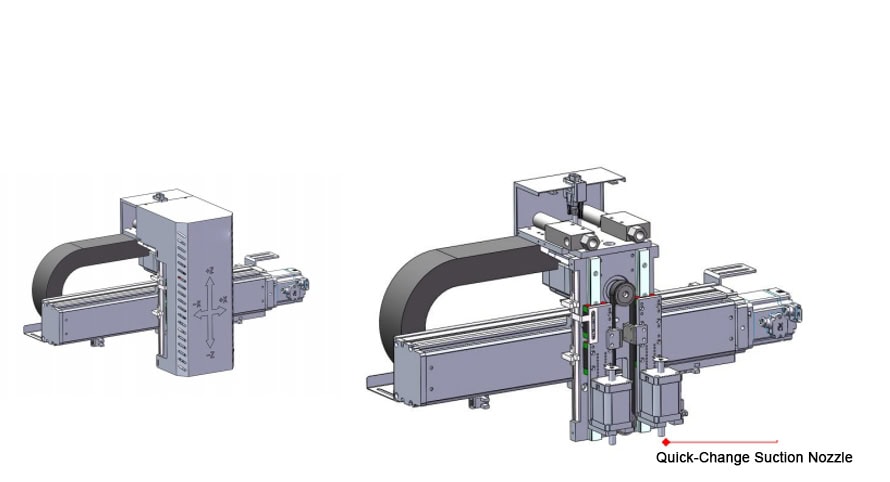

The equipment is comprised of three main components: a feeder system, a visual positioning system, and a product feeding positioning system. These components operate independently yet are interrelated, offering a broad range of applications. The motion mechanism’s hardware features high-precision ground screws and branded electrical accessories, ensuring the equipment’s stability and reliability.

|

Accuracy:

|

±0.1mm

|

|

CCD Model:

|

Upper camera: 5MP, 3072×2048

Lower camera: 1.3MP, 1024×768 |

|

Industrial Light Source:

|

Upper light source: through-hole surface

Lower light source: coaxial |

|

Labeling Speed:

|

15~25pcs/ min

|

|

Application label size:

|

60 *60mm; T: 0.05~0.5mm

|

|

Application Product Size:

|

100~140mm; T: 0.4~30mm

|

|

Position Type:

|

CCD position

|

|

Transportation Direction:

|

Left to right &right to left

|

|

Label Angle:

|

360˚

|

|

System Interface:

|

MES/ERP etc.

|

|

Application label OD:

|

Φ300mm

|

|

Application label ID:

|

φ76mm

|

|

Weight:

|

200kg

|

|

Voltage:

|

AC220V 50Hz

|

|

Air Pressure:

|

0.4~0.7Mpa

|

|

Power:

|

About 2500W

|

|

Machine size:

|

1300mm×800mm×1700mm(L×W×H)

|

High Precision Labeling:

Utilizes a CCD camera system for accurate label positioning, ensuring precise application on specified product locations.

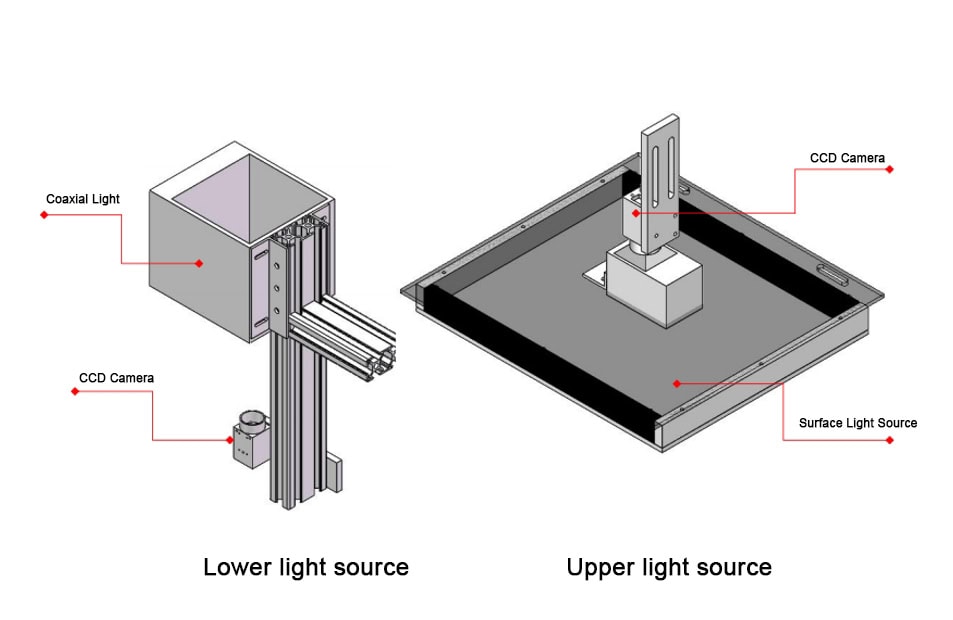

Dual Camera System:

Equipped with an upper 5MP camera (3072×2048 resolution) and a lower 1.3MP camera (1024×768 resolution) for comprehensive visual positioning.

Advanced Lighting:

The upper light source adopts through-hole surface lighting, and the lower light source uses a coaxial light source for enhanced image capture.

Stable Operation:

Incorporates high-precision ground screws and branded electrical accessories for reliable and stable performance.

Versatile Application:

Suitable for a wide range of industries, including electronics, pharmaceuticals, food and beverage, healthcare, daily chemicals, light industry, agricultural products, tobacco, hardware, seafood, and logistics.

Efficient Design:

Consists of three main systems—feeder, visual positioning, and product feeding positioning—that operate independently but are interrelated, providing a comprehensive labeling solution.

User-Friendly Interface:

Features an intuitive software control system, making it easy to operate and adjust for different labeling tasks.

High Speed and Accuracy:

Capable of labeling at speeds of 15-25 pcs/min with a labeling accuracy of ±0.1mm.

USB Data Export:

Facilitates easy data transfer and management with USB data export capability.

The Vision Labeling Machine is designed for high-precision product application. Its main application fields include:

The conveyor belt uses a stepper motor, which, through CCD recognition, ensures precise product stop positioning. It can also automatically lift up to 100mm in height and has bidirectional input and output capabilities.

The CCD Camera Visual Flat Labeling Machine is highly versatile and can seamlessly integrate with other equipment to enhance its functionality. By connecting to an industrial label printer, it can achieve real-time printing of label content, ensuring up-to-date and accurate labeling. Additionally, it can be linked to a collection system, which automatically gathers and organizes products after labeling. This integration capability makes the machine an essential component in streamlined and efficient production lines, further improving productivity and accuracy.

LabeMachine is a specialized manufacturer of labeling machines and complementary equipment. Our main products include wire labeling machines, bottle labeling machines, flat labeling machines, packaging machines, and filling machines. We are committed to providing high-quality, reliable solutions for all your labeling and packaging needs. more+

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more