Honeycomb Paper Making Machine Manufacturer

We are a professional manufacturer of honeycomb paper making machines, specialized in producing eco-friendly and biodegradable honeycomb paper. This paper is easy to stretch, has high formability, and is used for packaging various products, providing cushioning and decorative functions. The equipment can achieve a production speed of up to 150 meters per minute, with automatic unwinding and rewinding features.

Application Demonstration

Honeycomb eco-friendly paper can be used for packaging and protection of various products, they can be degraded quickly in the natural environment, which is a new type of environmentally friendly packaging materials

How is it made?

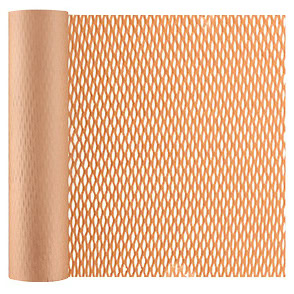

Honeycomb paper can be used for packaging due to its three-dimensional shape of honeycomb after being cut by machines. When the paper is stretched, you can see that there are many holes like honeycomb.

At this point it is no longer a flat piece of paper, but three-dimensional, can be used to wrap glass bottles, porcelain, fruit, flowers and other items. This honeycomb eco-friendly paper plays a cushioning holding role as well as being a nice decoration.

What’s more, it is made of environmentally friendly biodegradable materials, which can be naturally degraded in the natural environment without polluting the environment.

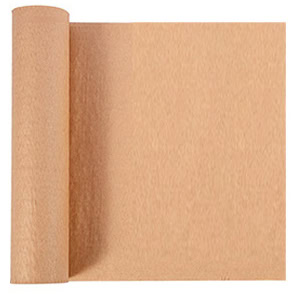

Before stretching

The machine cut honeycomb paper has a small footprint and is easy to use. They are made in the form of rolls and the shape of the honeycomb is not visible until it is stretched.

After stretching

When honeycomb paper is stretched, it takes on the shape of a honeycomb of holes and is no longer a flat sheet of paper, but rather a three-dimensional shape.

About us

We are a professional manufacturer specializing in the production of automated equipment. Our primary focus is on packaging machinery, such as the advanced honeycomb paper making machines we are currently featuring.

Available in both semi-automatic and fully automatic models, our machines utilize state-of-the-art automation control systems and cutting-edge processing technologies. The core component of our equipment, the die-cutting roller, boasts an impressive lifespan of up to 3 million meters.

Additionally, our machines are equipped with an automatic correction system to ensure smooth and uniform paper winding, preventing any misalignment issues during the process.

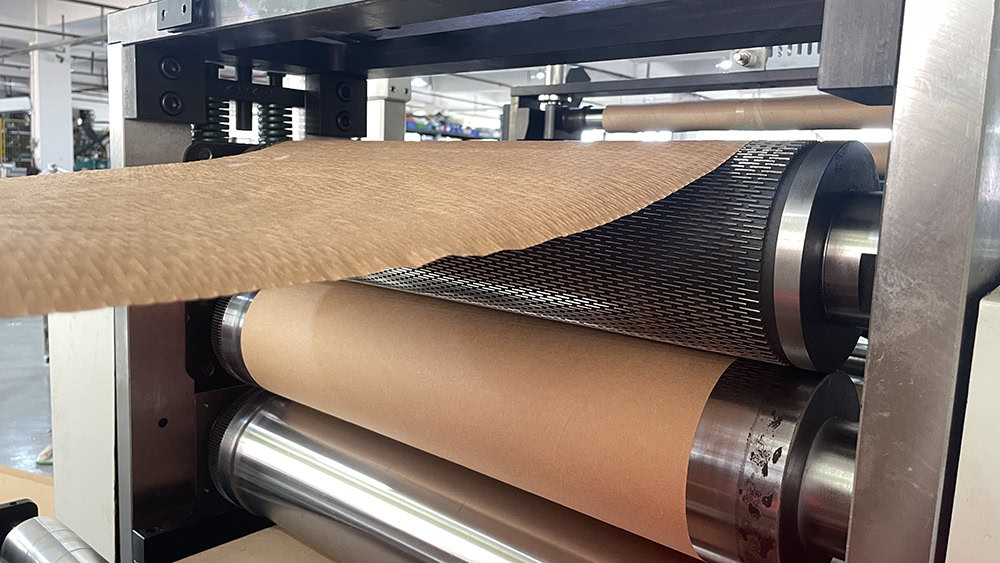

Details of the machine

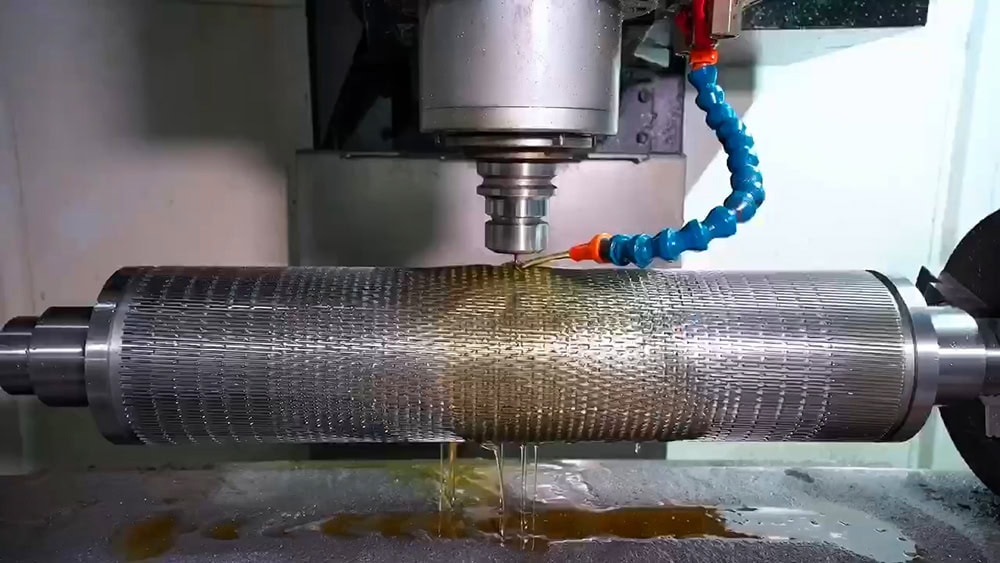

Die-cutting Roller

The die-cutting roller is a critical component of our machine, responsible for creating precise slits in the paper. This process is the most crucial step in the machine’s operation, as it directly determines the quality of the final product.

Die-cutting rollers in process

The precision and sharpness of the die-cutting roller are essential, as they ensure that each cut is clean and accurate, leading to a superior finished product. Our advanced technology allows the die-cutting roller to maintain its high precision and sharpness, providing consistent and excellent performance throughout its extensive lifespan of up to 3 million meters. This longevity ensures reliable operation and superior quality in every production run.

Automatic Alignment System

The machine is equipped with an advanced Automatic Alignment System, designed to ensure that the eco-friendly paper remains perfectly aligned throughout the feeding and processing stages. This system plays a crucial role in maintaining the accuracy and consistency of the paper, resulting in neatly produced paper tubes.

Paper rolls

Our equipment is designed to accommodate a wide range of raw material diameters, with a maximum capacity of up to 500mm. This flexibility allows for efficient processing of larger paper rolls, making our machines suitable for various production needs and enhancing overall productivity.

Equipment Performance

High performance

leads to high efficiency

After several iterations, the machine is now capable of producing up to 150 meters/minute.

Up to 5 tubes can be rotated at the same time and up to 5 tubes can be wound up.

The roll is the core component of the machine, which can continuously cut 3 million meters of environmentally friendly paper.

Semi-automatic Honeycomb Paper Making Machine

Model Number:

SXY-550-SEMI

Dimension Parameters:

3550mm x 1260mm x 1680mm(L x W x H)

Speed:

5~280m/min

Effective Width of Die-cutting Stick:

550mm

Effective Unwind Width:

540mm

Power:

5 KW

Voltage:

380V / 50HZ

Weight:

1800 KG

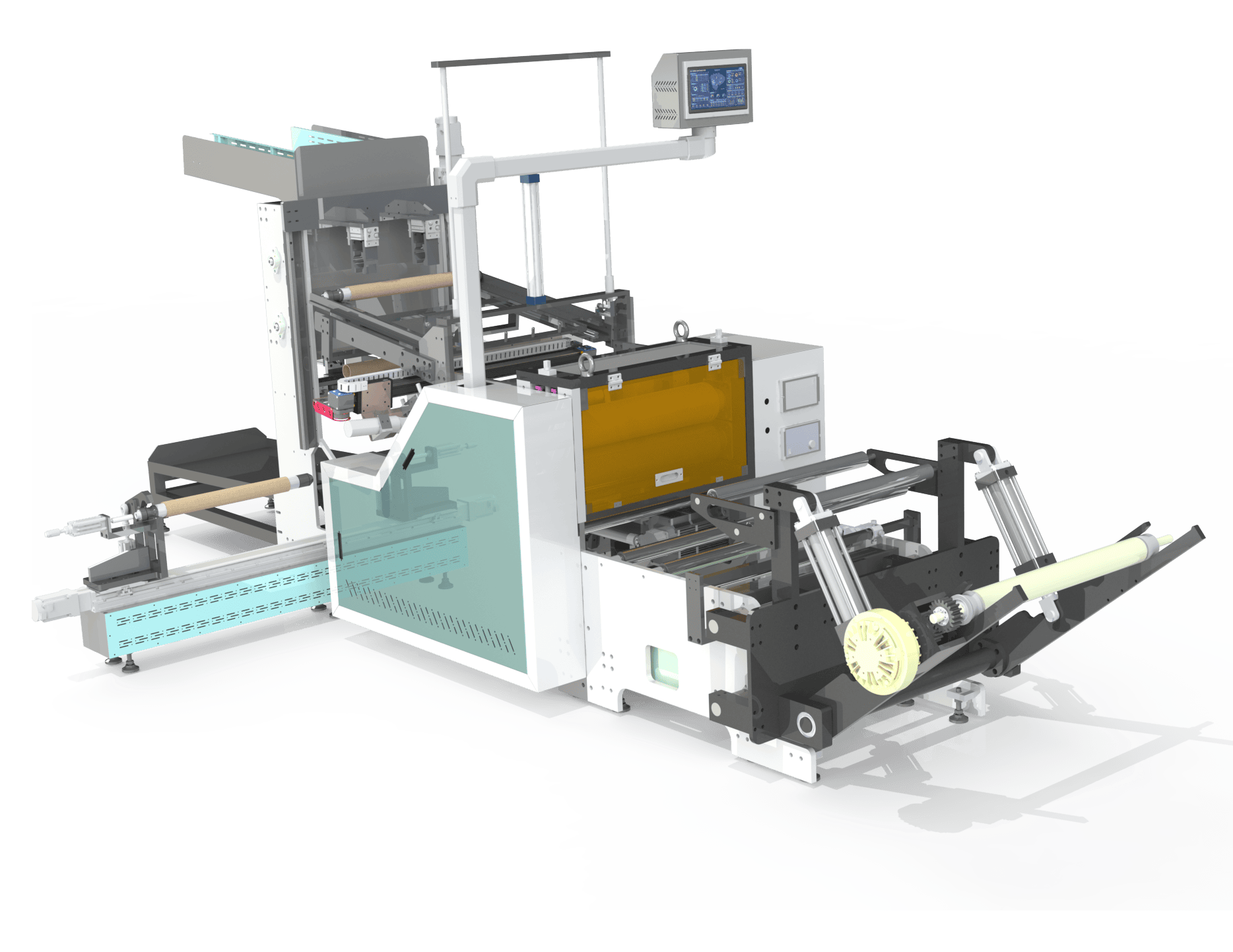

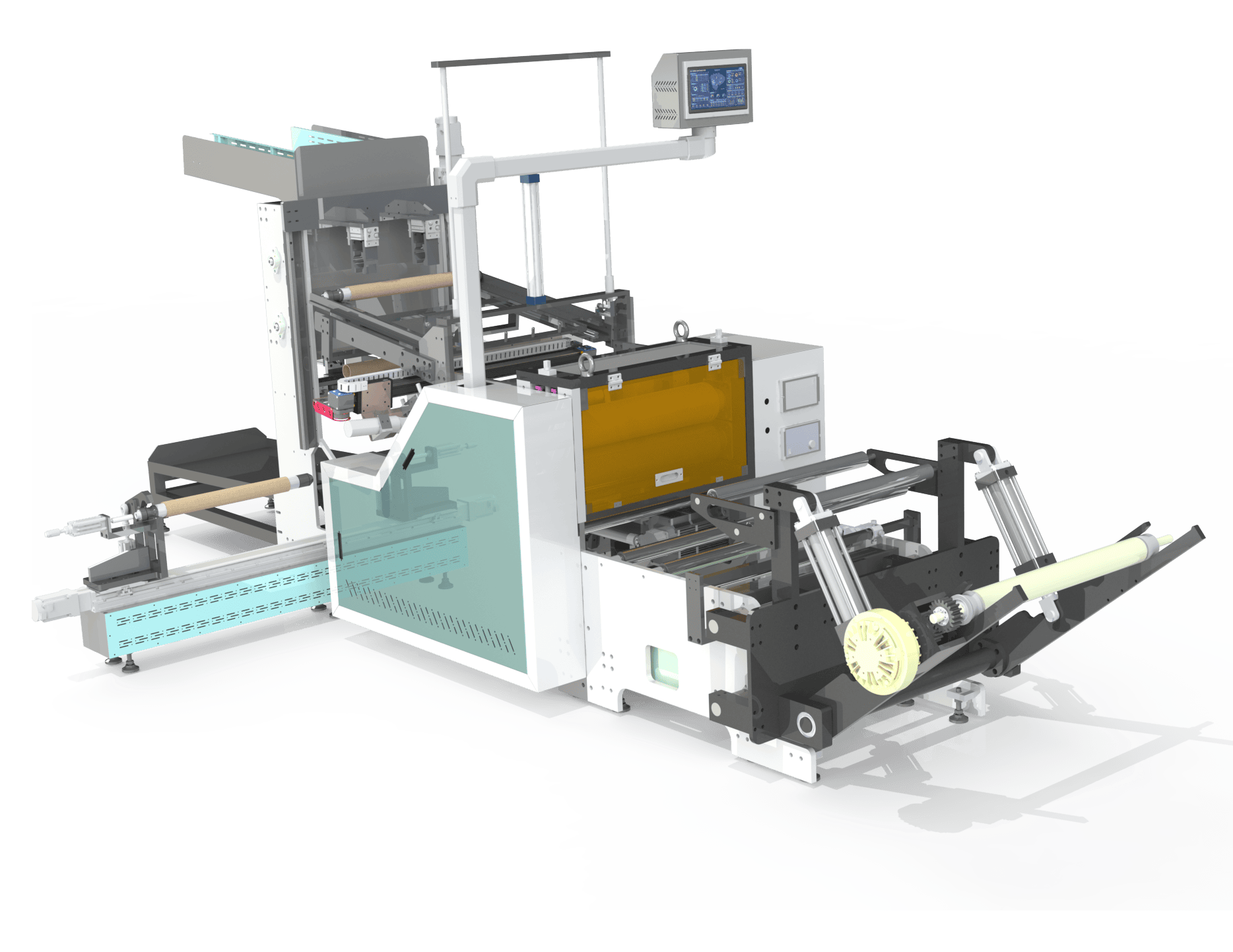

Automatic Honeycomb Paper Making Machine

Model Number:

SXY-550-AUTO

Dimension Parameters:

4840mm x 2288mm x 2100mm(L x W x H)

Speed:

5~280m/min

Effective Width of Die-cutting Stick:

550mm

Effective Unwind Width:

540mm

Power:

6 KW

Voltage:

380V / 50HZ

Weight:

2500 KG

Equipment configuration list

Semi-Automatic Honeycomb Paper Making Machine

- Automatic Roll Changer

1pc; Pneumatic paper tube + to number automatic cutting + to number automatic feed storage

- Die-cutting Roll

1pc; ∅240 x 600, Helical Teeth

- Die-cutting Bottom Roller

1pc; ∅240 x 600, Alloy Stell + Main Servo Drive

- Rwinder Unit

1pc; ∅300, Rubber Roller Fricton Winding

- Automatic Feeding Device

1pc; 1.5 KW Hydraulic System

- Automatic Alignment System

1pc; 110 Synchronous Motor Electric Cylinder Alignment Correction

Automatic Honeycomb Paper Making Machine

- Automatic Roll Changer

1pc; Automatic paper tube loading +Automatic pneumatic expansion shaftloading + Automatic air pumping +Automatic placement of pneumaticexpansion shaft + Automatic withdrawaof the pneumatic expansion shaft afterwinding + Automatic placement offinished products

- Die-cutting Roll

1pc; ∅138 x 600, Helical Teeth

- Die-cutting Bottom Roller

1pc; ∅138 x 600, Alloy Stell + Main Servo Drive

- Rwinder Unit

1pc; ∅300, Rubber Roller Fricton Winding

- Automatic Feeding Device

1pc; 1.5 KW Hydraulic System

- Automatic Alignment System

1pc; 110 Synchronous Motor Electric Cylinder Alignment Correction

Contact Us

- Your information are secure and confidential.