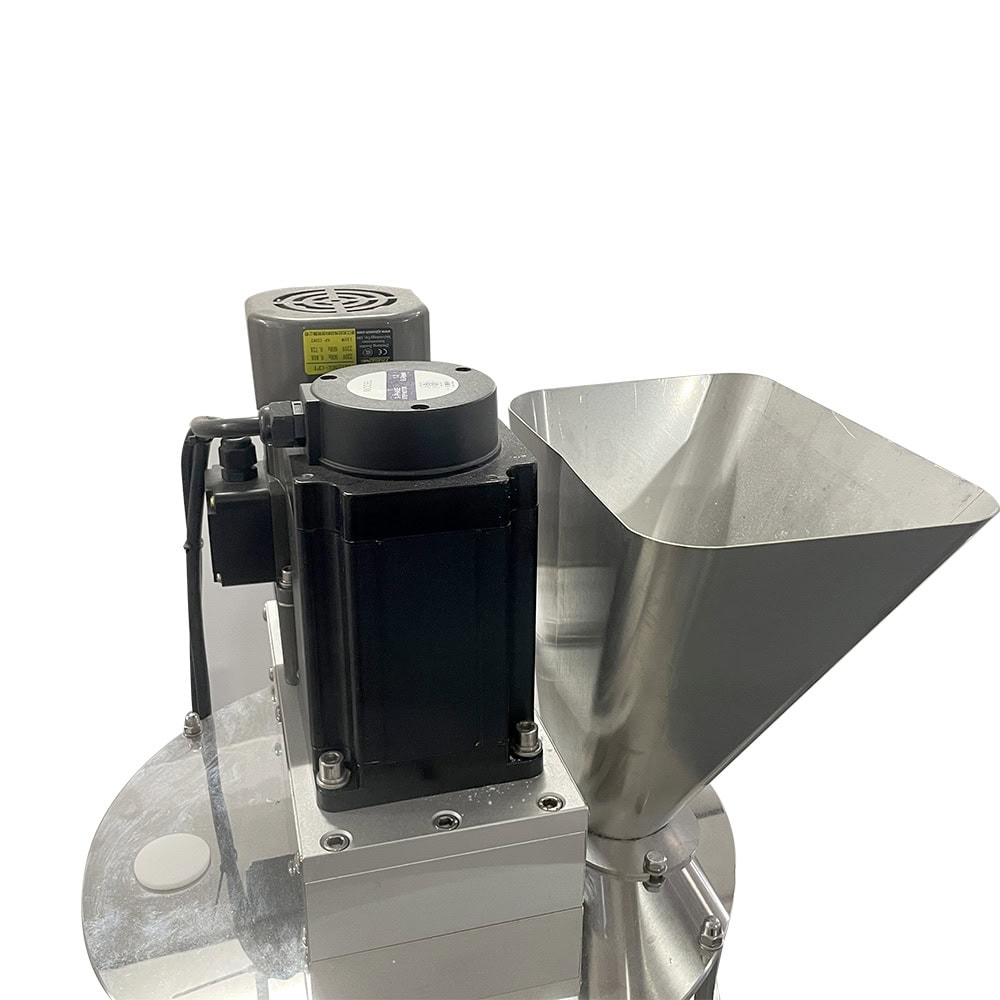

The Fully Automatic Powder Filling Machine efficiently fills bottles with powders and granules. It features servo motor control, a stainless steel structure, and a touch-screen interface for easy operation.

| Weight | 130 kg |

|---|---|

| Dimensions | 1500 × 660 × 1820 mm |

| Production capacity | 15~25 bottles/bag/min |

| Hopper capacity | 15L |

| Packaging capacity | 0.1~0.5g; 1~10g; 10~50g; 50~200g; 100~1000g |

| Power | 2KW |

| Feeding power | 2.2KW |

The Fully Automatic Powder Filling Machine is designed to handle the precise and efficient filling of bottles with powders and small granular materials. This advanced machine can automatically position bottles, fill them with the desired quantity, measure the fill, and transport them down the production line. The system comprises a screw metering machine, a chain conveyor belt, and a pneumatic positioning device, and it can be seamlessly integrated with additional equipment such as a bottle unscrambler, capping machine, and coding machine to form a complete filling line. It is ideal for packaging various powders and granules, including pharmaceuticals, milk powder, spices, powdered additives, glucose, solid beverages, talcum powder, toner, dyes, and fragrances.

The Fully Automatic Powder Filling Machine is perfect for a wide range of industries and applications, particularly for those requiring the packaging of powders and small granules. Key applications include:

|

Production Capacity

|

15-25 bags or bottles/min

|

|

Hopper Capacity

|

15L

|

|

Filling Range

|

0.1-0.5g; 1-10g; 10-50g; 50-200g; 100-1000g

(different screw attachments required for different ranges)

|

|

Dimensions

|

1500x660x1820mm

|

|

Weight

|

130 KG

|

|

Power

|

2KW/220V

|

|

Feeder Power

|

2.2 KW

|

This Fully Automatic Powder Filling Machine is an essential tool for businesses looking to automate and optimize their powder and granular product-filling processes, offering versatility, precision, and ease of use.

LabeMachine is a specialized manufacturer of labeling machines and complementary equipment. Our main products include wire labeling machines, bottle labeling machines, flat labeling machines, packaging machines, and filling machines. We are committed to providing high-quality, reliable solutions for all your labeling and packaging needs. more+

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more