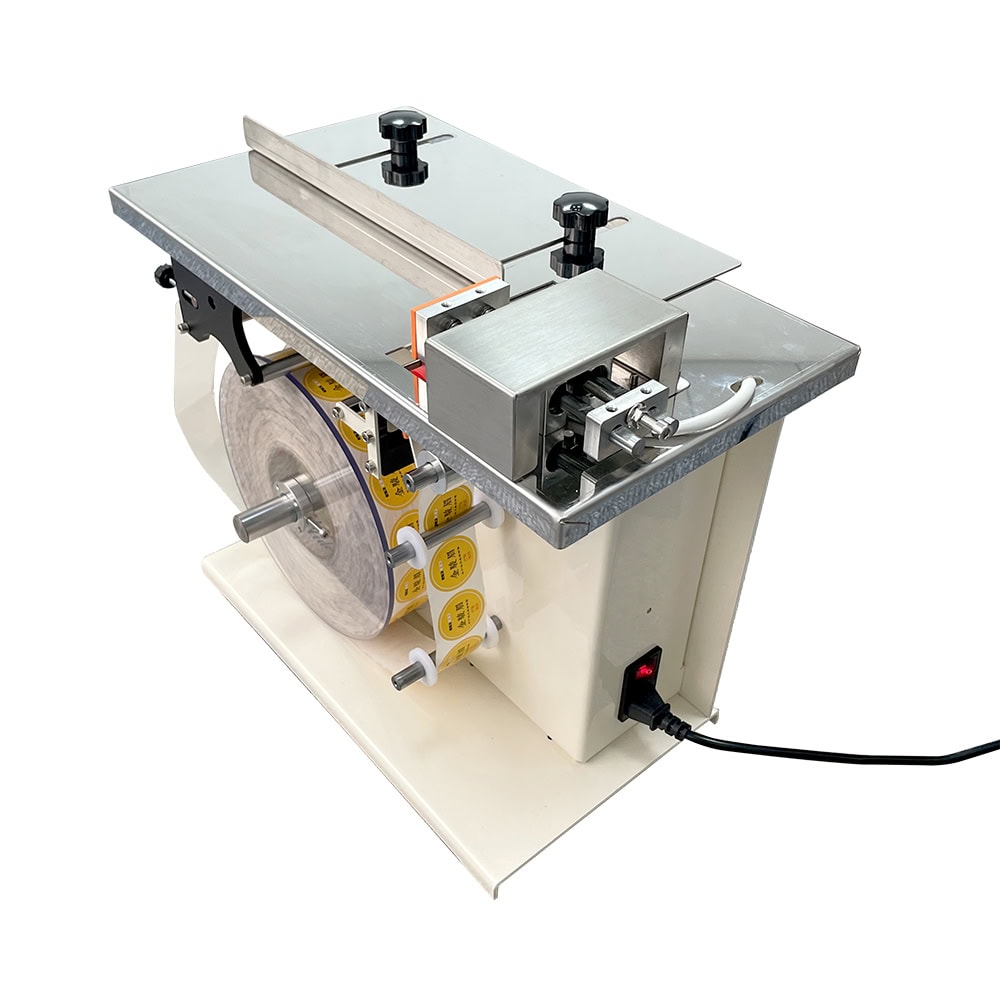

The Box Corner Labeling Machine is designed for precise 90-degree angle labeling, ideal for sealing and anti-tampering applications in various small boxes. It is compact, easy to operate, and perfect for small businesses and home workshops. With a labeling speed of 35-90 pcs/min and accuracy of ±0.5mm, this machine is suitable for industries such as cosmetics, pharmaceuticals, electronics, and more.

| Weight | 15 kg |

|---|---|

| Dimensions | 400 × 220 × 360 mm |

| Labeling Accuracy | ±1mm (excluding product and label errors) |

| Labeling Speed | 0~40 pcs/min |

| Product Size | Based on actual products |

| Label Size | Diameter: 15~50mm |

| Label roll size | Outer Diameter: ≤ 200mm, Inner Diameter: 76mm |

| Power Supply | 220V/50HZ(modifiable) |

The Box Corner Labeling Machine is specifically designed for small businesses, providing an efficient solution for sealing and labeling the corners of various small boxes. This machine applies corner sealing labels that both secure the box and display important product information. With a labeling speed of up to 50 pcs/min and an accuracy of ±1mm, it ensures precise and reliable labeling.

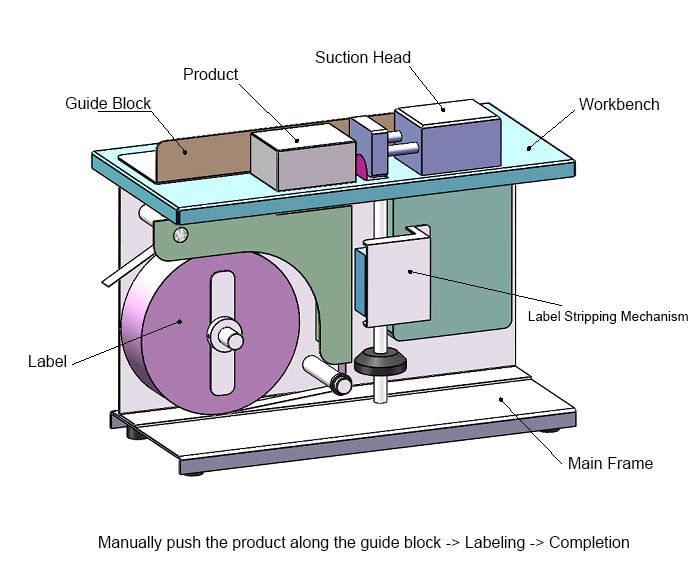

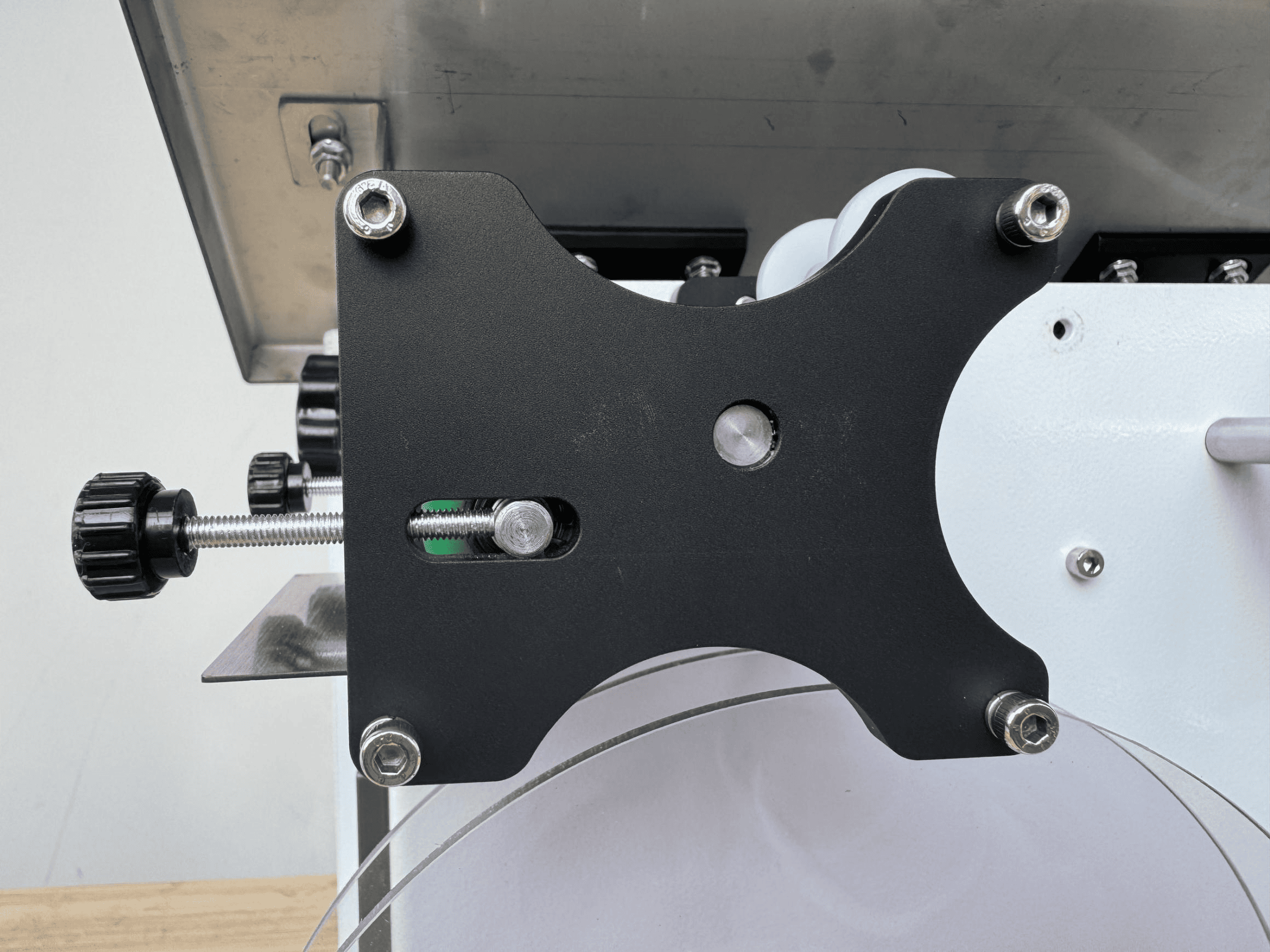

Compact and user-friendly, the Box Corner Labeling Machine is small enough to fit on your desk and is incredibly easy to operate. Simply connect the power, switch it on, and press start on the screen to begin labeling. You only need to push the product along the guide plate to complete each labeling process.

This machine is perfect for home workshops or individuals running e-commerce businesses, making it an ideal choice for efficient product labeling. If you need a more versatile corner labeling machine, check out this semi-automatic square bottle corner labeling machine of ours.

Target Customers: Small and medium-sized enterprises, home workshops, and other small-scale production clients.

|

Labeling Accuracy:

|

±1mm

|

|

Weight:

|

15 kg

|

|

Dimensions:

|

400 × 220 × 360 mm

|

|

Labeling Speed:

|

0~40 pcs/ min

|

|

Application label size:

|

Diameter: 15~50mm

|

|

Application Product Size:

|

Based on actual products

|

|

Label roll size:

|

Outer Diameter: ≤ 200mm, Inner Diameter: 76mm

|

|

Voltage:

|

AC220V 50Hz

|

Control System:

Key Components:

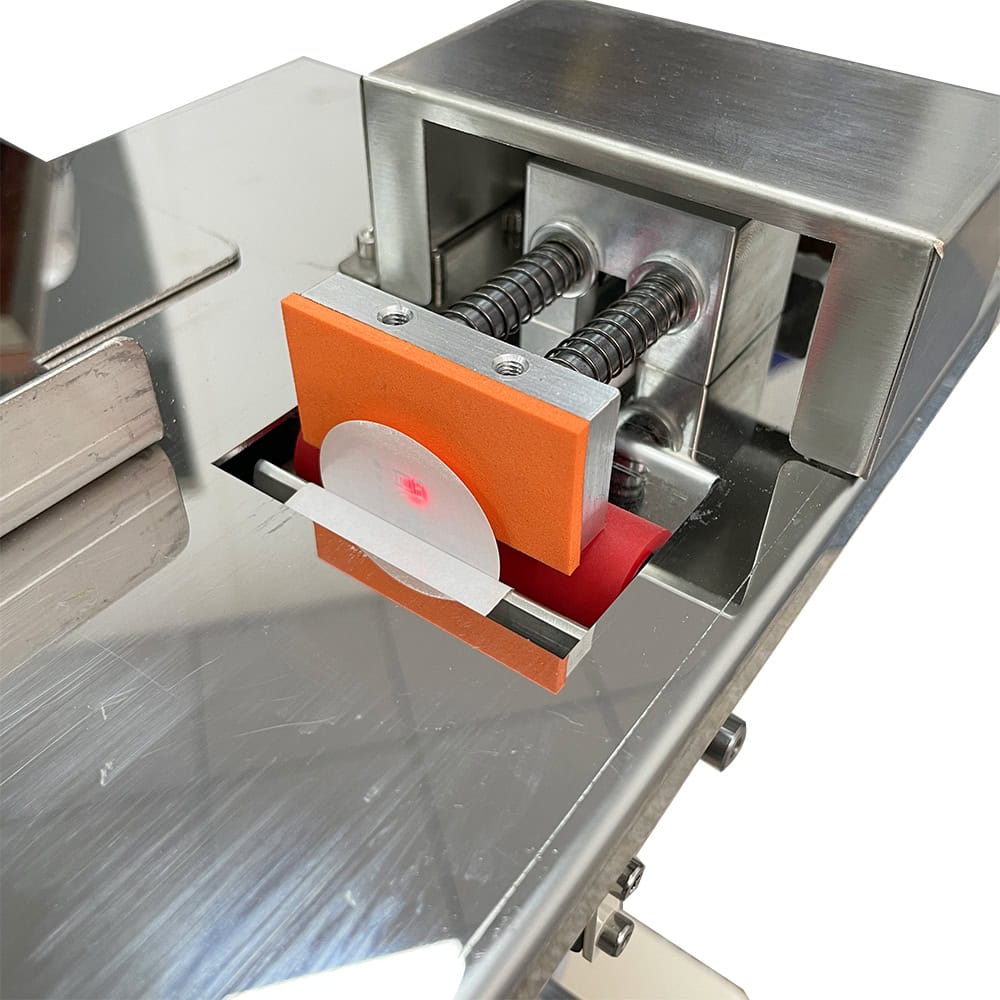

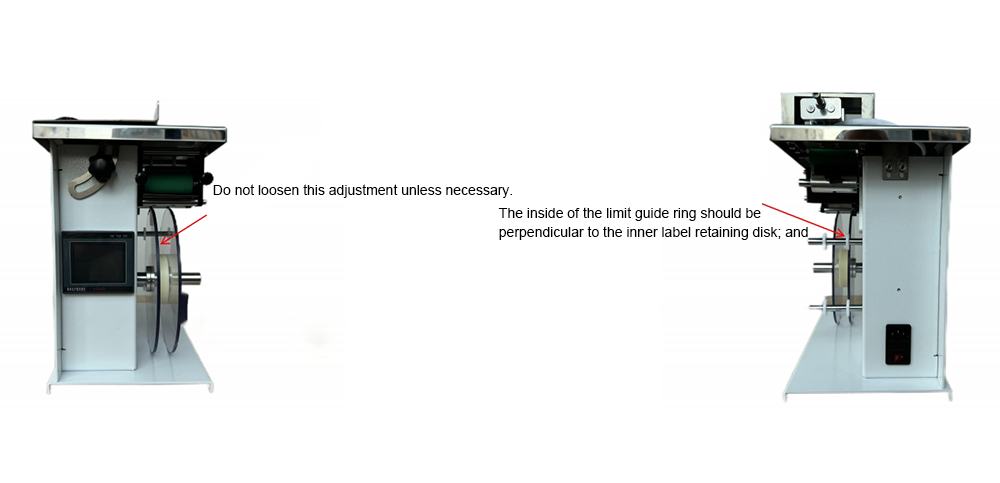

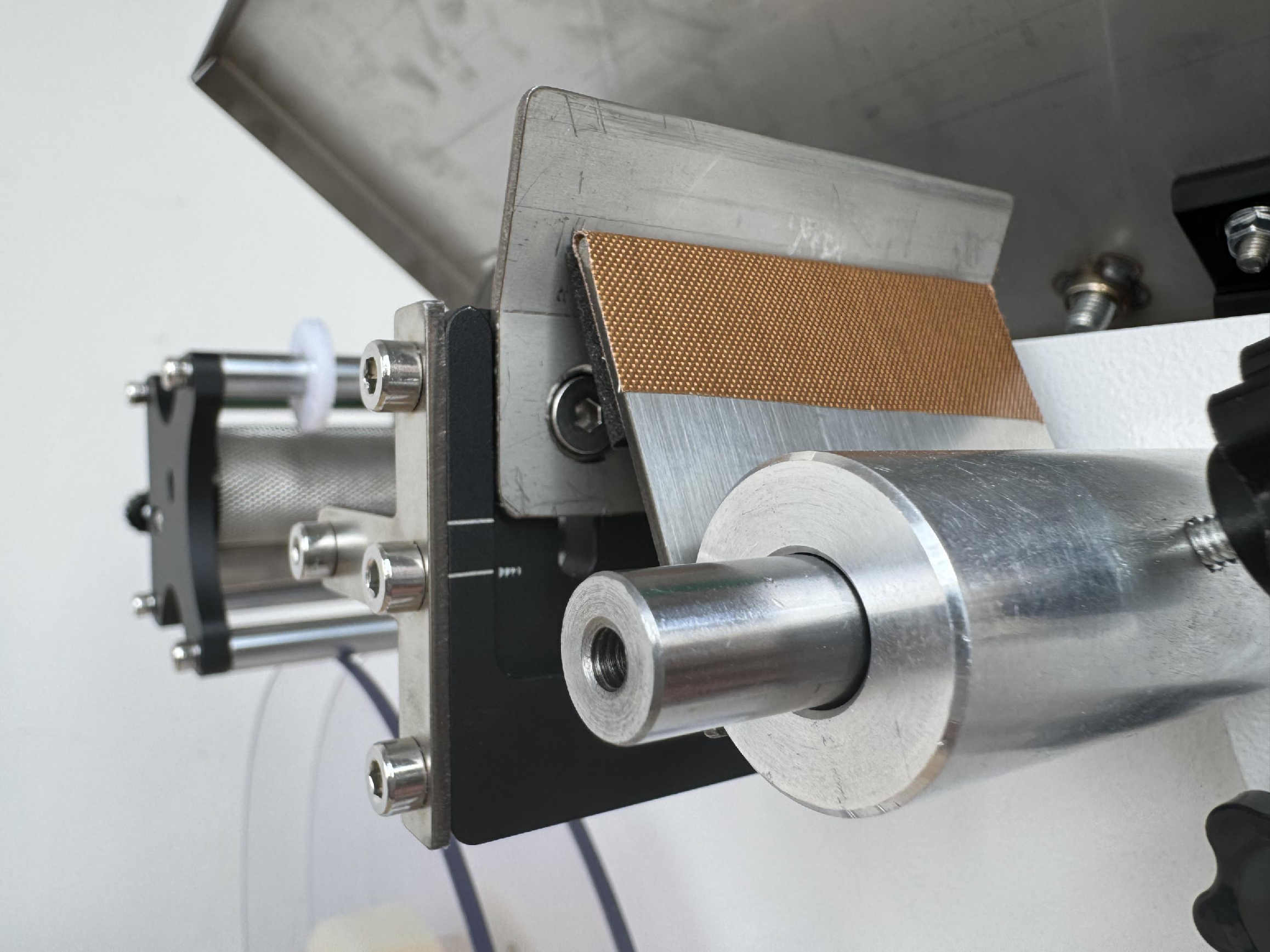

Label Peeling Knife Fixed Positions:

Label compression plate should be located in the position of about 5MM above the crease of the peeling knife.

Slave shaft locking device label through the two sides of the hand screw tight (pressure on the good, do not need too much force)

LabeMachine is a specialized manufacturer of labeling machines and complementary equipment. Our main products include wire labeling machines, bottle labeling machines, flat labeling machines, packaging machines, and filling machines. We are committed to providing high-quality, reliable solutions for all your labeling and packaging needs. more+

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more