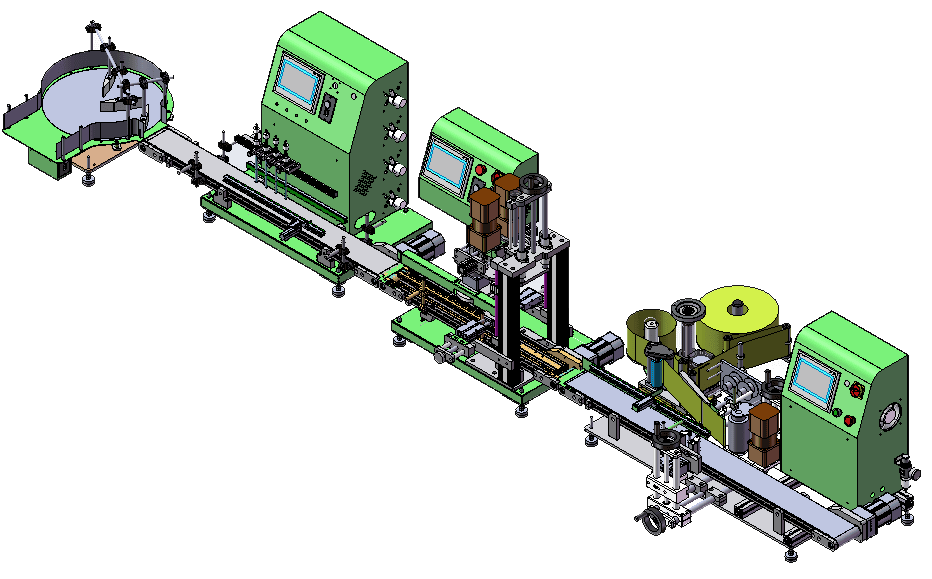

A 3-in-1 water filling machine integrates three key processes—washing, filling, and sealing—into a single, streamlined system. Without this kind of integrated solution, bottling operations would face inefficiency, higher labor costs, and potentially lower hygiene standards.

A 3-in-1 water filling machine combines washing, filling, and capping into one integrated system. The process is efficient, hygienic, and ideal for large-scale bottling operations.

Let’s delve into the detailed working principle of the 3-in-1 system to understand its core processes.

Washing Process

The first stage of the process in a 3-in-1 water filling machine is washing. Bottles are fed into the washing station, where they are cleaned with high-pressure jets and brushes. These jets effectively remove any dirt, dust, or residues from the bottles’ surface. The washing system is essential for maintaining hygiene standards in the production process, ensuring that contaminants do not affect the quality of the water.

The washing process also includes a sterilization step where bottles are sanitized with disinfectant, ensuring that the bottles are completely clean before the filling process begins. This stage is automated, which reduces human error and minimizes the time spent on cleaning.

Filling Process

After washing, the bottles move to the filling station. The filling process uses either a gravity or pressure system to dispense the water into each bottle. Gravity filling involves the liquid flowing into bottles under its own weight, whereas pressure filling uses air pressure to fill bottles more rapidly, ensuring precise liquid levels.

The filling valves are designed to prevent spills and maintain a uniform liquid level. The accuracy of this process is crucial for both quality control and efficiency, as it prevents overfilling or underfilling, which could lead to waste or customer dissatisfaction.

Capping Process

Once the bottles are filled, they proceed to the capping station. This part of the machine applies caps to each bottle, effectively sealing it. Various capping methods can be employed, such as screw caps, twist-off caps, or snap-on caps, depending on the bottle design and product requirements.

The capping process also ensures that the bottles are sealed tightly to prevent leakage or contamination. Some 3-in-1 machines also include cap sterilization systems, ensuring that even the caps are clean and sterile before being applied to the bottles.

Automation and Control

One of the key advantages of a 3-in-1 water filling machine is the level of automation it offers. Automated systems and sensors monitor the entire process to ensure precision at every stage. For example, the filling process uses sensors to detect when the bottle is in position and ensures that the correct amount of liquid is dispensed.

This automation not only improves the consistency and quality of the finished product but also significantly reduces the need for human intervention, which lowers the risk of contamination and human error. The automated controls can also adjust speeds, detect malfunctions, and ensure that the system operates efficiently at all times.

Production Capacity Considerations

3-in-1 water filling machines can be customized to suit different production volumes. Depending on the scale of the bottling operation, the system can be configured to handle small, medium, or large batches. High-speed rotary filling systems can process thousands of bottles per hour, making them suitable for mass production.

Customization also extends to the types of bottles that can be processed, allowing flexibility in terms of size and material. Whether the production line is focused on small bottled water containers or large commercial-sized bottles, the 3-in-1 machine can accommodate these needs.

Efficiency and Cost Reduction

The primary benefit of a 3-in-1 water filling machine is its ability to significantly increase production efficiency. By combining the three essential processes—washing, filling, and capping—into one streamlined system, it eliminates the need for separate machines, reducing both capital investment and operational costs.

Additionally, the automation of these processes reduces the need for labor, which is a significant cost-saving factor. The system’s speed and precision allow for a high throughput, enabling manufacturers to meet large production demands without compromising quality or hygiene standards.

Types of 3-in-1 Filling Machines

There are different types of 3-in-1 filling machines available to cater to different production requirements. Some are designed for small-scale operations, while others are built for high-capacity, high-speed bottling lines. The size of the filling valves and the number of heads in the system can vary, offering flexibility in terms of both output and bottle size.

Some systems are also designed to be more energy-efficient, using less water and energy during the washing and filling processes. These machines can be particularly appealing to companies looking to reduce their environmental impact and operational costs.

Maintenance and Cleaning

Like any other automated machinery, a 3-in-1 water filling machine requires regular maintenance to ensure that it operates at peak efficiency. Routine maintenance includes checking the filling valves, cleaning the filling and washing systems, and inspecting the capping station for wear and tear.

The machine’s cleaning process is also automated, ensuring that the system is thoroughly cleaned between production runs. This helps maintain hygiene standards and prevents cross-contamination between different batches.

Conclusion

The 3-in-1 water filling machine is an essential piece of equipment for large-scale bottling operations. By combining washing, filling, and capping in one integrated system, it enhances production efficiency, reduces labor costs, and maintains high hygiene standards.