Choosing the wrong packaging solution, like stretch hood or stretch film, can result in compromised product security and increased operational costs. Selecting the right option ensures efficient packaging and reduced losses.

Stretch hood and stretch film serve distinct purposes in the packaging industry. Stretch hood involves using tubular film to tightly wrap loads, offering excellent protection, while stretch film uses single-layer plastic wrap for manual or machine application.

What is a Stretch Hood?

Definition and Mechanism

Stretch hood is a tubular film that stretches and securely encapsulates loads, ensuring stability. This system typically requires automated machinery and is preferred for high-volume operations.

Material and Properties

Made from linear low-density polyethylene (LLDPE), stretch hood delivers elasticity and superior load protection. Its high tensile strength makes it a durable choice for industries requiring robust packaging.

What is Stretch Film?

Definition and Mechanism

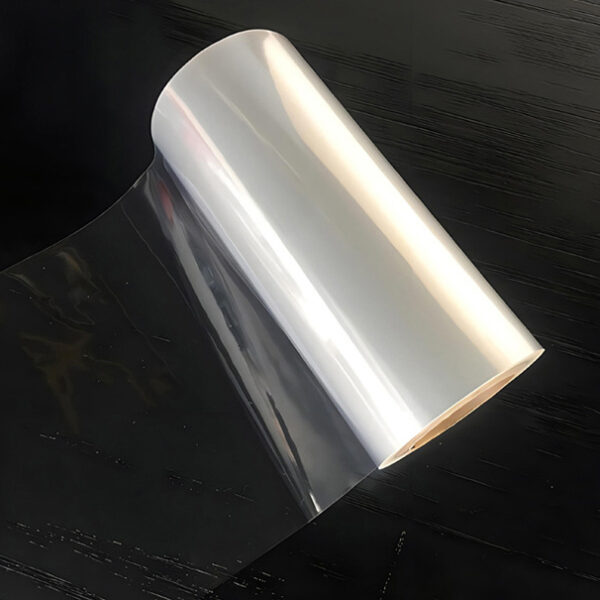

Stretch film, also known as stretch wrap, is a single-layer plastic film wrapped around loads manually or with machines. It secures items by applying tension to the film, ensuring stability during transportation.

Material and Properties

Available in blown or cast varieties, stretch film emphasizes flexibility and adaptability. Its puncture resistance and varying stretch levels make it suitable for diverse load types.

Comparing Cost and Efficiency

Cost Implications

Stretch hood systems involve a higher upfront cost due to the need for specialized machinery. However, they save on labor and reduce material waste over time. Stretch film, by contrast, is more affordable initially but may incur higher labor expenses in the long run.

Efficiency and Speed

Stretch hood provides faster packaging for uniform loads, making it ideal for industries like beverage manufacturing or logistics. Stretch film, while versatile, can be slower for large-scale operations.

Protection and Load Security

Load Stability

Stretch hood offers excellent stability for uniform pallets, protecting against water and dust. It’s a go-to solution for industries like construction and electronics.

Environmental Protection

Stretch film adequately secures loads but may not provide the same level of resistance to environmental factors like moisture or UV light.

Industry Applications and Compatibility

Use Cases

Stretch hood is often used in industries like beverage and construction, where uniform loads require durable packaging. Stretch film, meanwhile, is preferred in logistics and retail for its adaptability to irregularly shaped or diverse loads.

Compatibility

Stretch hood systems excel with consistent pallet dimensions, while stretch film adapts to various load shapes, making it a more versatile option for general use.

Environmental Impact

Stretch Hood

By using less material per load, stretch hood systems are eco-friendly and generate minimal waste. They are particularly favored for sustainable packaging goals.

Stretch Film

While stretch film may generate more waste, innovations like recyclable or downgauged films are helping industries reduce environmental footprints.

Conclusion

Stretch hood and stretch film address unique packaging needs, and the choice depends on factors like load type, operational scale, and cost. Companies can ensure optimal performance by selecting the right solution for their industry requirements. For example, businesses using shrink wrap machines and label printers often integrate stretch film for enhanced efficiency