Many businesses and individuals face confusion when it comes to choosing between a label printer and a label maker. Without understanding the differences, you might end up with the wrong tool for your labeling tasks, leading to inefficiencies, wasted resources, and frustration. To avoid these issues, it’s crucial to understand the distinctions between these devices, ensuring you select the right one for your needs.

Label printers and label makers are both used for creating labels, but they differ significantly in their functionality, design, and ideal use cases. A label printer offers more customization options and is connected to a computer for designing labels, whereas a label maker is a standalone, simpler device often used for quick, basic labeling tasks.

Let’s dive deeper into the key differences between label printers and label makers to help you make the right decision for your business or personal use.

What is a Label Printer?

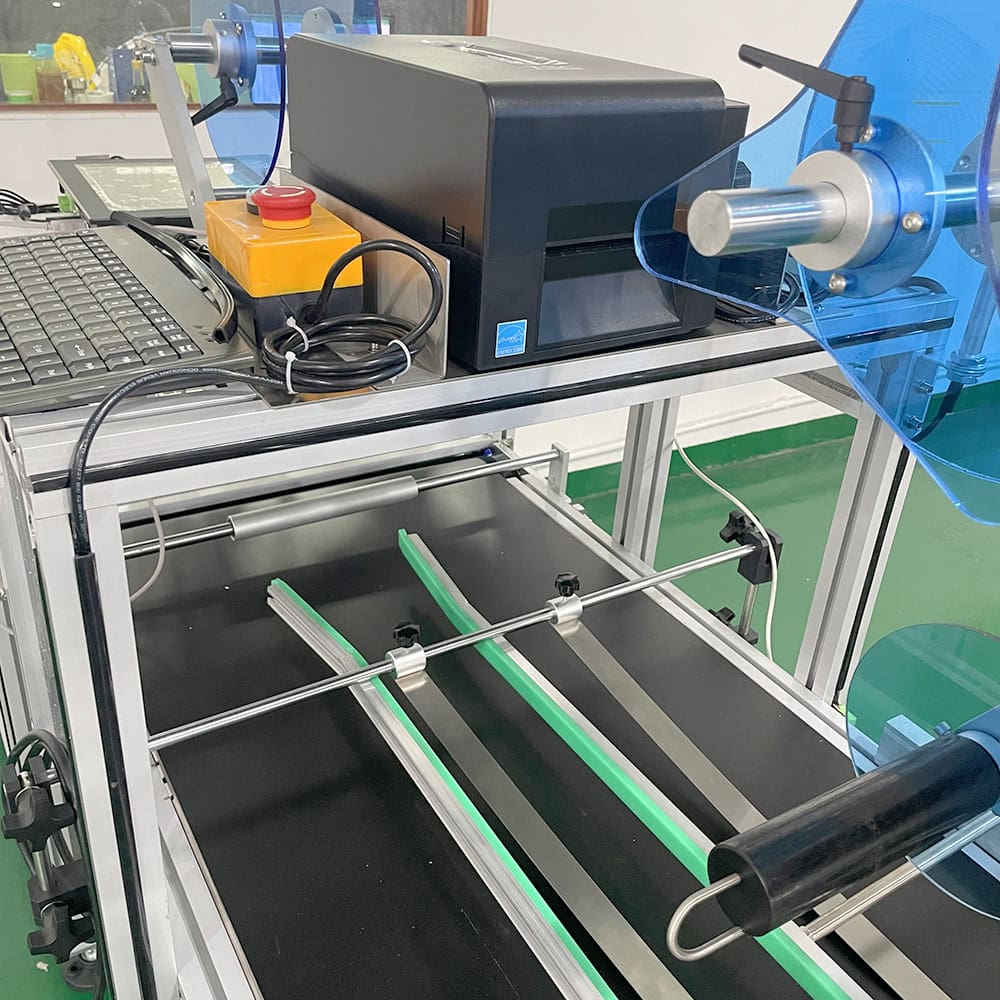

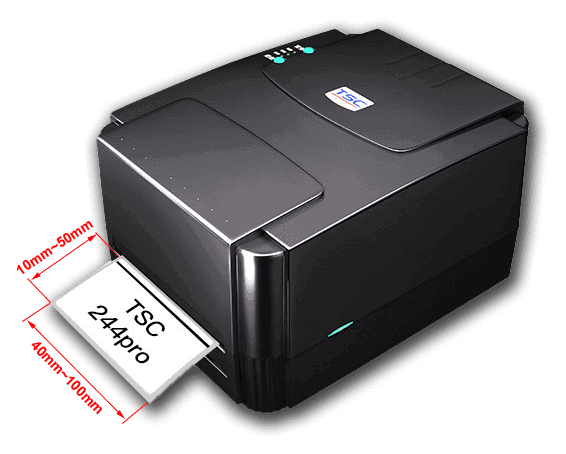

A label printer is a device designed specifically to print high-quality labels. These devices use advanced technologies such as thermal, inkjet, or laser printing to transfer text, graphics, and barcodes onto a variety of label materials, including paper, plastic, and fabric. Label printers are often used in industries where custom labeling is essential, such as retail, logistics, and inventory management.

Key Features of Label Printers:

- Customization: Label printers are highly versatile, allowing for custom designs, logos, barcodes, and multiple fonts. This flexibility is especially beneficial for companies that need to produce professional and unique labels.

- Connectivity: These printers typically require a connection to a computer, smartphone, or tablet for design and printing. They may use software like Adobe Illustrator or specialized labeling programs to create detailed designs.

- Print Quality: Label printers offer higher resolution and better quality printing compared to label makers. This ensures that text, logos, and barcodes appear sharp and clear.

- Speed and Efficiency: Label printers are ideal for bulk label printing and large-scale operations. They can print hundreds or even thousands of labels in a short time, making them a must-have for businesses with high labeling demands.

- Cost: While more expensive than label makers, label printers are a valuable investment for businesses that require consistent, high-quality labeling.

What is a Label Maker?

A label maker is a compact, standalone device that is typically used for creating simple text-based labels. These devices are often favored for personal or small business use, as they are quick and easy to operate, with no need for a computer connection.

Key Features of Label Makers:

- Simplicity: Label makers are designed for ease of use. They have a small keyboard or interface that allows users to type in text, and the device prints directly onto label tape.

- Portability: Label makers are lightweight and portable, which makes them ideal for small office or home use. They don’t require a computer or other external equipment to function.

- Text-Based Labels: Unlike label printers, which allow for complex designs, label makers typically focus on producing simple text labels. They are best suited for labeling folders, files, or everyday items.

- Affordability: Label makers are generally more affordable than label printers, making them an economical choice for personal use or small businesses with less demanding labeling needs.

- Limited Features: While label makers may offer a few basic graphics and fonts, they lack the advanced design features of label printers.

Key Differences Between Label Makers and Label Printers

- Customization Options: Label printers provide far more customization options, allowing users to design detailed labels with graphics, logos, and barcodes. Label makers, on the other hand, focus on text-based labels with limited customization.

- Connectivity: Label printers require a computer or smartphone connection to create and send designs, while label makers operate as standalone devices, making them easier to use for quick tasks.

- Print Quality and Speed: Label printers are designed for high-volume, high-quality printing, ideal for businesses that need consistent, professional labels. Label makers are slower and produce lower-quality prints, mainly suited for simple labels.

- Price: Label printers are more expensive due to their advanced features and higher print quality. Label makers are more affordable and are designed for personal or small business use.

- Label Material Compatibility: Label printers are versatile and can print on various materials like thermal paper, adhesive-backed rolls, and specialty materials. Label makers typically use a specific type of label tape.

- Usage Complexity: Label printers require more setup and software knowledge, while label makers are user-friendly, allowing for quick label creation without technical knowledge.

- Ideal Use Cases: Label printers are perfect for industries requiring high-quality, custom labels for products, packaging, or inventory management. Label makers are better suited for personal or simple office tasks.

- Portability: Label makers are compact and portable, while label printers are usually larger and intended for stationary use.

- Maintenance: Label printers require regular maintenance and software updates, while label makers generally have minimal maintenance needs.

- Durability: Label printers are typically built to handle large volumes and more complex tasks, while label makers are best for light-duty applications and quick, low-volume labeling.

Can You Use a Printer as a Label Maker?

In some cases, you can use a regular printer as a label maker, especially if you use label sheets or rolls compatible with inkjet or laser printers. However, this approach can be more time-consuming and may not provide the same ease of use or convenience as a dedicated label maker. Additionally, printing labels with a standard printer usually requires more manual setup, making it less efficient for businesses or individuals who need to print large quantities of labels.

If you’re looking for a quick solution, it’s better to invest in a label maker for simple tasks. For more complex and high-volume labeling needs, a label printer remains the best option.

What is Another Name for a Label Printer?

A label printer is sometimes referred to as an “industrial label printer,” particularly when used in large-scale manufacturing and distribution environments. These printers are designed to print high volumes of labels with various designs and are capable of handling continuous or roll-fed labels. In some cases, label printers are also known as “barcode printers” when their primary function is to print barcodes for inventory tracking and product labeling.

What is the Difference Between a Label Printer and a Regular Printer?

While both label printers and regular printers can print text and images, label printers are specifically designed to print on adhesive materials such as label rolls or sheets. Regular printers, like inkjet or laser printers, are designed for printing on paper and are not as efficient at printing on specialized label stock. Furthermore, label printers offer higher quality and resolution suitable for labels that need to withstand wear and tear, such as those used for products or shipments.

What Type of Printer is Best for Labels?

When choosing a printer for labels, thermal label printers are often considered the best option due to their high-speed printing, cost efficiency, and ability to handle various label materials. These printers are ideal for businesses that need to print a large volume of labels quickly and accurately. Inkjet and laser printers can also be used for labels, especially if high-quality color graphics are required, but they are less efficient for bulk printing compared to thermal printers.

Conclusion

Understanding the differences between a label printer and a label maker can help you choose the right tool for your labeling needs. Label printers are perfect for businesses that require customized, high-quality labels in large volumes, while label makers are more suited for personal use or small labeling tasks. Whether you’re looking for a labeling machine for mass production or a bottle labeling machine for your packaging line, it’s important to assess your specific needs before making a decision.