One of the things people struggle with is deciding between a label maker and a label printer because they don’t understand the differences. Not knowing the differences can lead to a lot of frustration and wasted time and money.

The difference between a label maker and a label printer is how they are designed and used. A label maker is a little portable unit you can carry around to do simple labeling. A label printer is something that connects to your computer and is used for high volume, more complex label printing.

To help you make an educated decision, let’s talk about the differences between the two.

Definition of a Label Maker

A label maker is a compact, handheld device designed for on-the-go use, offering a quick and simple way to create labels. These devices are typically found in homes or small offices and are used to organize files, containers, or personal belongings. Label makers are often battery-operated and feature built-in keyboards and screens, making them entirely independent of computers or other external systems.

The ease of use and portability make label makers an attractive option for individuals who need to produce labels intermittently. However, their simplicity limits their capacity for customization, as they typically support only basic fonts and sizes.

Definition of a Label Printer

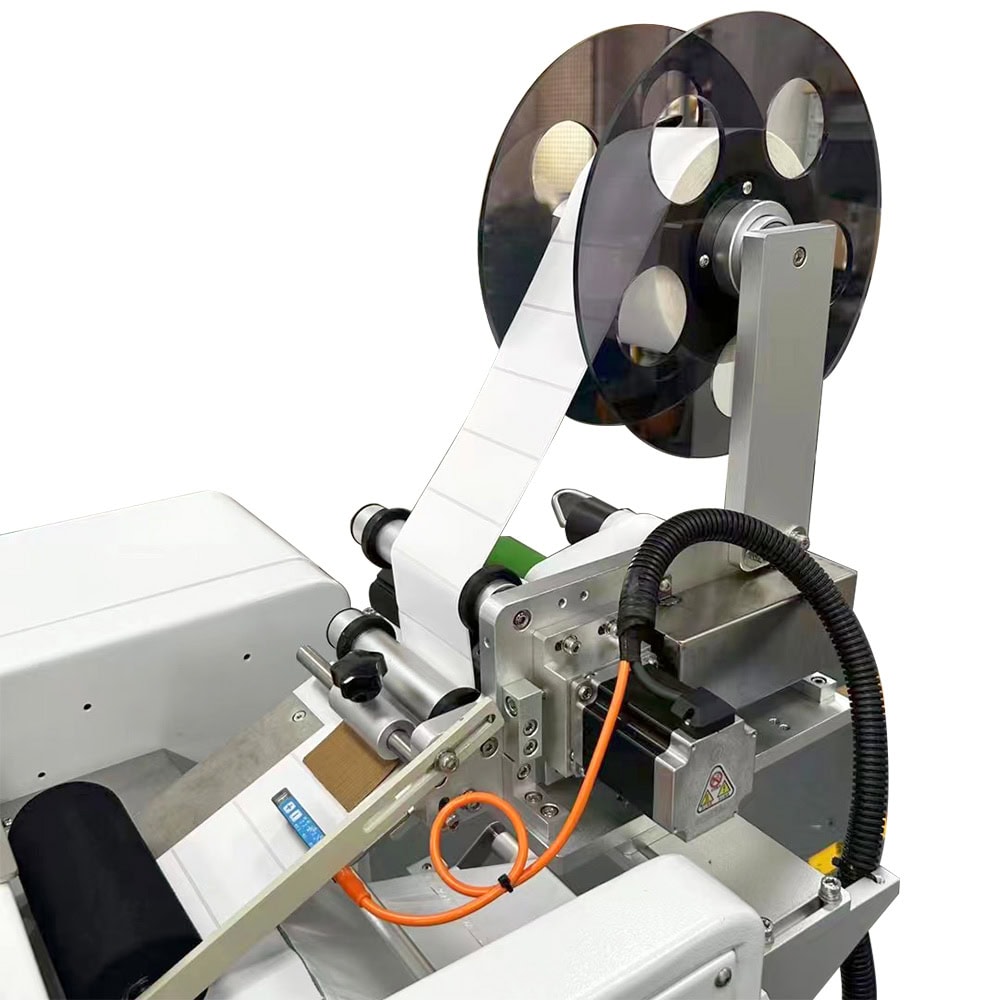

On the other hand, a label printer is a more complex and powerful machine that connects to a computer or network to produce labels. These devices are most often used in business environments where high-volume, high-quality labels are required. From product labels and barcodes to shipping labels, a label printer can handle a wide range of tasks with greater customization options than a standard label maker.

Label printers come with software that allows for advanced designs, including different fonts, colors, logos, and barcodes, making them indispensable in industries like packaging and manufacturing. Whether you’re printing product labels on a Flat Labeling Machine or high-speed barcode labels with an industrial label printer, these devices are built for efficiency.

Primary Use Cases

Label Maker:

A label maker is best suited for personal or light office tasks. It is commonly used for labeling file folders, storage bins, and household items. This tool provides the flexibility to organize your space quickly and efficiently, though it is limited in scope for professional use.

Label Printer:

A label printer is designed for businesses that require high-quality, large-volume label production. Ideal for manufacturing, shipping, and inventory management, a label printer produces durable labels that can include graphics, barcodes, and custom fonts. For instance, when paired with a packaging machine, the labels printed on a label printer enhance the branding and information displayed on products.

Size and Portability

Label Maker:

Label makers are compact and lightweight, designed for mobility. They are easy to carry around, fitting into a drawer or bag when not in use. The portability makes it a convenient option for those needing labels in different locations.

Label Printer:

Conversely, label printers are generally larger and require a stationary setup. They need to be connected to a computer and power supply, making them less mobile but much more efficient for high-volume tasks. The trade-off for their size is the ability to produce detailed, professional labels, crucial for businesses utilizing devices like Bottle Labeling Machines and barcode printers.

Connectivity and Compatibility

Label Maker:

A label maker operates independently without needing any external connections. It features a built-in screen and keyboard, enabling users to create labels directly on the device. However, this lack of connectivity limits its functionality compared to label printers.

Label Printer:

Label printers often need to connect to a computer or mobile device, allowing integration with various software for advanced design and printing capabilities. This connection enables greater flexibility in label creation, such as generating barcodes for inventory systems or printing high-quality labels for shipping.

Customization Options

Label Maker:

Customization in label makers is relatively limited. Users can choose from a handful of fonts, sizes, and symbols, but the scope for creative or detailed label designs is minimal.

Label Printer:

Label printers offer extensive customization. Through software, users can incorporate a wide range of fonts, colors, graphics, and even barcodes into their labels. Whether printing product tags, branding materials, or barcodes for inventory management, the design options are nearly limitless.

Printing Speed and Volume

Label Maker:

Designed for low-volume printing, a label maker operates at a slower speed and is better suited for small tasks. The device is ideal for personal use or small-scale office labeling projects, producing labels on demand without significant time pressure.

Label Printer:

A label printer is built for high-volume tasks, capable of printing hundreds or even thousands of labels quickly and efficiently. Businesses with extensive labeling needs, such as those using a filling machine or packaging products, benefit from the speed and reliability of label printers.

Cost and Investment

Label Maker:

Label makers are more affordable, making them a popular choice for casual or small-scale users. They offer a cost-effective solution for creating labels, though their limited features may not justify the cost for businesses requiring advanced functionality.

Label Printer:

Label printers are a larger investment, both in terms of the machine itself and the consumables required, such as ink and specialized labels. However, for businesses, this investment pays off by providing the tools necessary for professional, high-volume labeling.

Media and Label Variety

Label Maker:

Label makers generally support only a few types of label sizes and materials. Their use is confined to standard office or home labels, which limits versatility.

Label Printer:

Label printers, on the other hand, can handle a broad range of media types, from simple adhesive labels to more specialized materials like waterproof labels, custom sizes, and even shrink wrap for packaging products. This versatility makes them ideal for industrial and commercial applications.

Maintenance and Consumables

Label Maker:

Most label makers use thermal printing technology, meaning they do not require ink or toner. This reduces maintenance and running costs, making them easy to operate.

Label Printer:

Label printers, particularly those designed for industrial use, may require ink, ribbons, and more frequent maintenance due to their heavy-duty usage. The costs of consumables and upkeep are higher, but these devices are designed for long-term, high-volume use.

Final Summary

Understanding the key differences between a label maker and a label printer can help you choose the right tool for your needs. Whether for home use or industrial-scale labeling, each device has its strengths and limitations.

You may be interested in: