Manual liquid filling can lead to production bottlenecks and inaccuracies, causing businesses to lose valuable time and resources. The automatic 4 heads liquid filling and sealing machine eliminates this problem by automating the process, ensuring efficient, precise, and scalable production.

An automatic 4 heads liquid filling and sealing machine is a high-speed device used for filling liquid products into containers and sealing them automatically. It is equipped with four filling heads, which can fill multiple containers simultaneously, improving production efficiency and reducing labor costs.

This versatile machine is crucial in industries like pharmaceuticals, cosmetics, and food production, delivering reliable, high-speed operations for both small and large-scale manufacturing processes.

Purpose of Automatic 4 Heads Liquid Filling Machines

The primary goal of the automatic 4 heads liquid filling machine is to automate the liquid-filling process, enhancing production speed while maintaining precision. Its multi-head design allows for multiple containers to be filled at once, which is crucial for industries with high production demands. It is widely used in pharmaceuticals, cosmetics, and beverage industries to streamline production and ensure high-quality output.

Moreover, integrating this machine into the production line minimizes human error and reduces product waste. When combined with packaging or labeling machines, it ensures a complete and efficient production process.

Principle of Operation

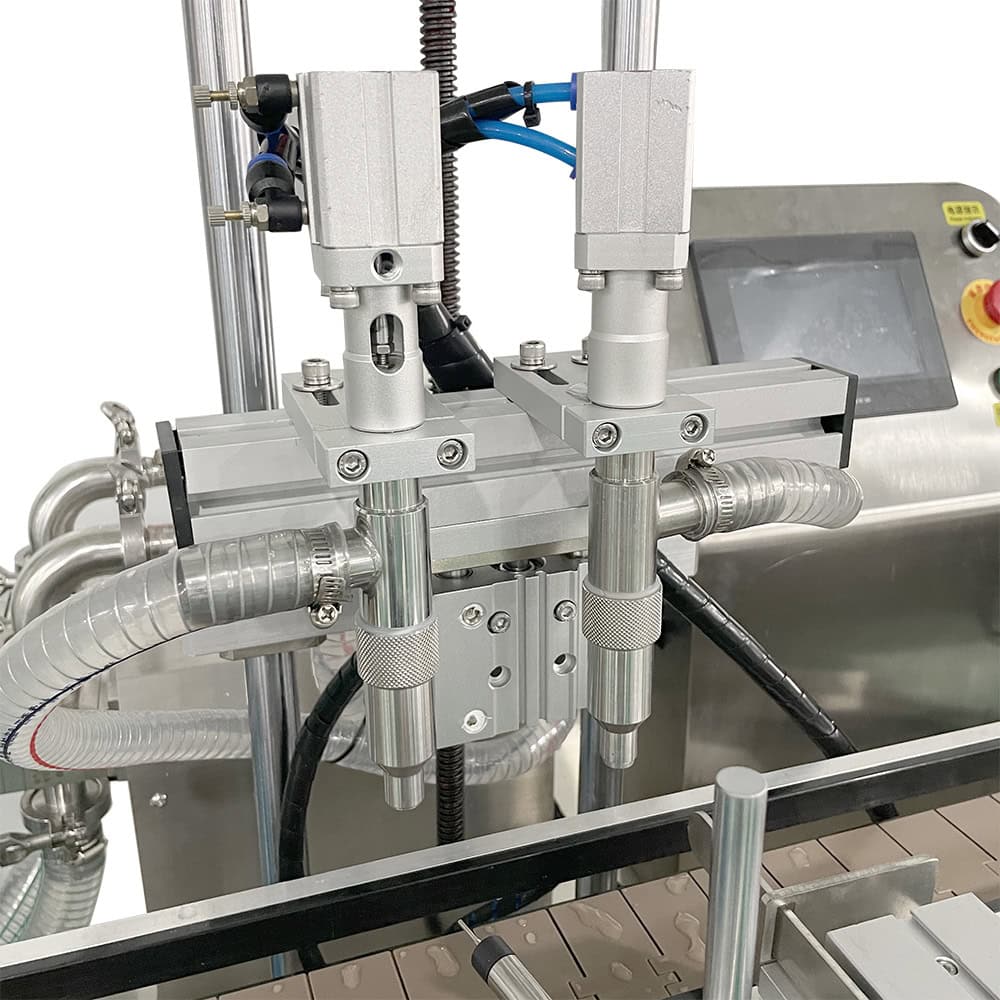

The automatic 4 heads liquid filling machine operates on a volumetric principle, where precise volumes of liquid are dispensed into containers. Each filling head is controlled individually, allowing the machine to fill different container sizes or volumes simultaneously. After filling, the containers are sealed, making the process more hygienic and reducing contamination risks.

For example, this machine can work seamlessly with bottle filling machines or labeling machines to ensure that after filling, the containers are sealed and labeled for the next step in the production process.

Increased Efficiency

The four-nozzle system dramatically increases productivity by filling multiple containers at once, reducing downtime and labor. This efficiency is further boosted by its automated sealing feature, which eliminates the need for manual intervention after the filling process.

By integrating with other production line machinery such as the shrink wrap machine or vacuum packaging machine, manufacturers can create a fully automated line that handles everything from filling to packaging.

Technical Specifications

Automatic 4 heads liquid filling machines come with a wide range of technical specifications that make them adaptable for various production needs. They are designed to fill different volumes, ranging from small 10ml bottles to larger containers. The adjustable filling nozzles can be modified to handle various container types and sizes, ensuring versatility in operations.

These machines typically feature a robust stainless steel construction to prevent corrosion, especially in food or pharmaceutical production environments. Most units are powered by PLC systems, which allow precise control over the filling process, ensuring accuracy within ±0.5ml. The sealing mechanisms can also be adjusted for different types of containers, making the machine highly adaptable for different production lines.

Enhanced Precision

Precision is one of the key advantages of the automatic 4 heads liquid filling machine. With advanced sensors and volumetric measurement, the machine ensures accurate filling for every container. This accuracy helps reduce waste and ensures consistent product quality.

In addition, when used in conjunction with a label printer, companies can achieve highly accurate labeling, ensuring that each container not only has the right amount of liquid but also the correct labeling for traceability and branding purposes.

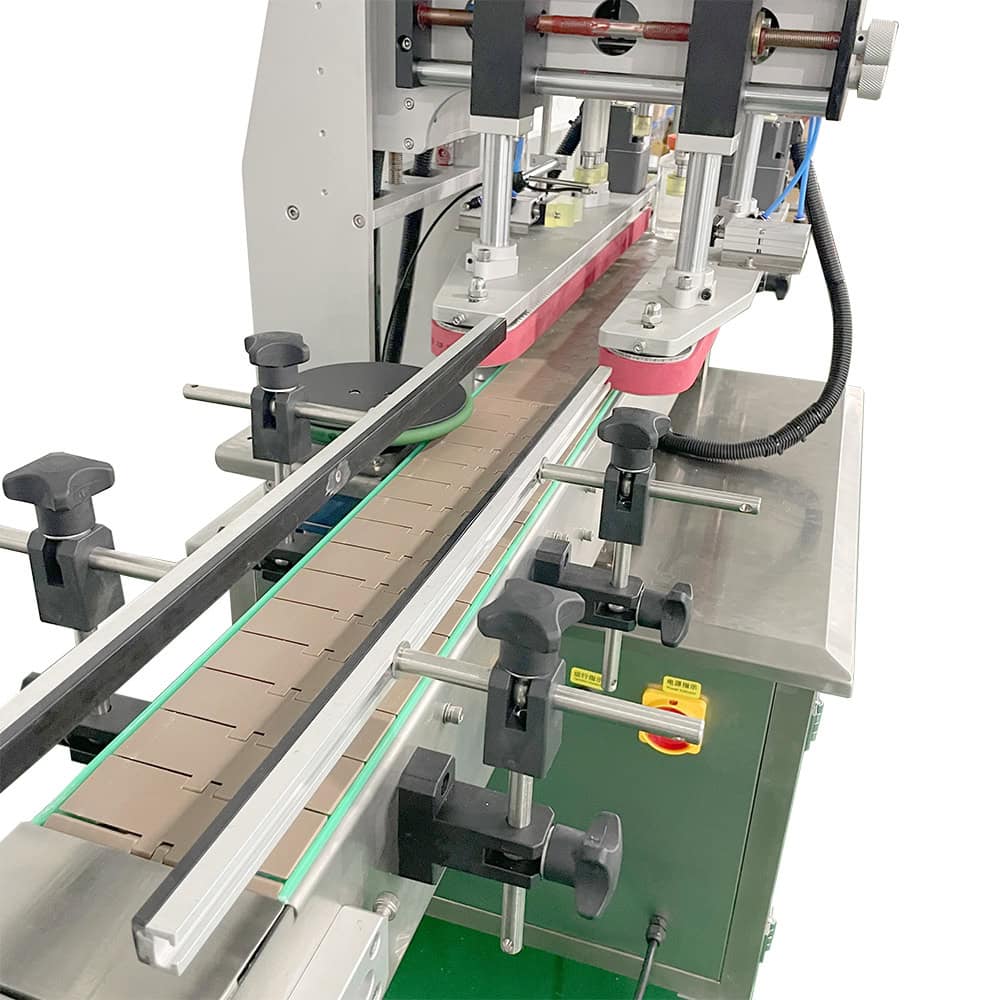

Automation in Sealing

The sealing aspect of this machine is just as critical as the filling process. It automatically seals each container after it is filled, offering a tamper-proof and hygienic solution. Sealing methods may vary depending on the type of container—whether it’s capping for bottles or heat-sealing for pouches.

This integrated sealing process works well with other machinery, such as the bottle capping machine, creating a fully automated packaging line. The automatic sealing reduces the risk of contamination and ensures that every container is securely closed before moving to the next stage of the production line.

Durability and Build

Manufactured from high-quality stainless steel, these machines are built to withstand continuous operation in industrial settings. Their robust construction ensures they can handle the demands of large-scale production, especially in sectors like food and beverage manufacturing.

Additionally, the design is compliant with safety standards, featuring emergency stop buttons and protective casings to prevent accidents. The machine’s durability makes it ideal for manufacturers seeking long-term reliability and low maintenance.

Integration with Production Lines

One of the key benefits of the automatic 4 heads liquid filling machine is its seamless integration with other production line equipment. The machine can be easily incorporated into an existing system, whether it’s bottle unscramblers, conveyors, or packaging machines, making the entire process more efficient.

By integrating with a customized labeling machine, manufacturers can achieve end-to-end automation from filling to sealing and labeling, increasing overall productivity and consistency in output.

Safety Features

Equipped with modern safety mechanisms, these machines include emergency stop buttons, sensor-based error detection, and automatic shut-off features. In case of any malfunction, the machine immediately halts operation to prevent accidents and protect both the operators and the production line.

The built-in sensors help detect any errors in the filling or sealing process, ensuring that any faults are caught early and rectified without affecting the production batch.

Customization Options

Automatic 4 heads liquid filling machines can be customized to suit specific production needs. Whether it’s adjusting the nozzle size, integrating a specialized barcode printer, or adding extra filling heads, the machine can be tailored for various applications. These customizations ensure that the machine meets the exact requirements of the production line, improving efficiency and reducing downtime for adjustments.

Manufacturers looking for more flexibility can opt for machines that feature interchangeable parts or modules, allowing them to switch between different products quickly. This versatility is especially beneficial for companies producing a range of liquid products requiring different packaging specifications.

Conclusion

The automatic 4 heads liquid filling and sealing machine is a vital tool for manufacturers aiming to increase efficiency, precision, and automation in their production processes. With its multi-head filling, robust construction, and seamless integration with other equipment, it offers a comprehensive solution for large-scale operations.