An inefficient packaging process can lead to damaged products and increased costs. If cartons aren’t sealed properly, it compromises the entire supply chain. The solution is an automatic carton sealing/taping machine, which ensures secure packaging and reduces human error.

An automatic carton sealing machine is a device used to apply adhesive tape to the top and bottom flaps of cartons. It automates the process, increasing efficiency and consistency in carton sealing, especially for high-volume operations.

Let’s explore how this machine works and the benefits it offers.

What is an Automatic Carton Sealing Machine?

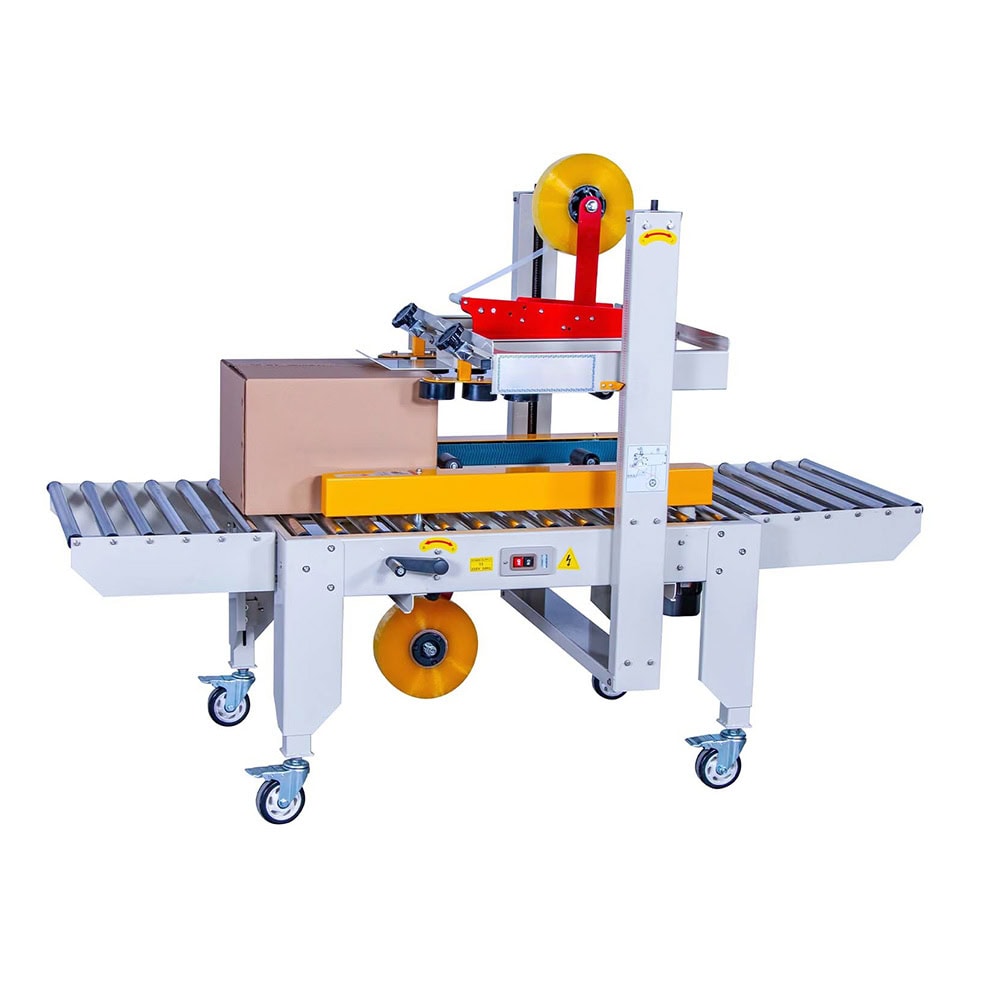

An automatic carton sealing machine is a piece of industrial equipment designed to seal cartons using adhesive tape. The machine is equipped with taping heads that apply pressure-sensitive tape to the top and bottom of the carton. It is widely used in industries such as food, logistics, and e-commerce, where quick, reliable sealing is essential to maintain the integrity of packaged goods.

In many settings, an automatic carton sealer replaces manual taping, reducing the time and labor required to seal each carton. It ensures that every box is sealed uniformly, which is crucial in preventing tampering or damage during transport.

How Does an Automatic Carton Sealing Machine Work?

Automatic carton sealing machines work by using a conveyor system to feed cartons through the machine. The sensors in the machine detect the dimensions of the carton, adjusting the taping heads accordingly. As the carton passes through, tape is dispensed from the heads and applied to the flaps, sealing them tightly.

The machine uses both top and bottom sealing heads, ensuring that the box is sealed on all sides. Some machines can adjust automatically to different box sizes, making them highly versatile in fast-paced production environments.

Types of Carton Sealing Machines

Semi-Automatic Carton Sealers

Semi-automatic machines require an operator to manually feed cartons into the machine, but the taping process is automated. These machines are suitable for smaller businesses or operations where flexibility is needed.

Fully Automatic Carton Sealers

Fully automatic machines do not require any manual input once the cartons are placed on the conveyor belt. They are equipped with sensors that detect carton sizes and adjust the taping heads automatically. This makes them ideal for large-scale operations where speed and consistency are key.

Benefits of Using an Automatic Carton Sealing Machine

- Efficiency: Automatic carton sealing machines dramatically speed up the packaging process. They can seal hundreds of cartons per hour, far surpassing manual methods.

- Cost-Effective: By reducing labor and minimizing tape waste, these machines lower overall packaging costs.

- Consistency: Each carton is sealed with uniform pressure and tape length, which ensures that all boxes meet quality standards.

- Versatility: Many machines can handle a wide range of carton sizes and adjust automatically, reducing downtime and increasing productivity.

- Protection: Well-sealed cartons are less likely to be damaged during shipping, which reduces product returns and increases customer satisfaction.

Key Features of an Automatic Carton Sealing Machine

- Adjustability: Automatic machines are capable of adjusting to different carton sizes, saving time and ensuring smooth operation.

- Durability: The machines are built with robust materials to handle high volumes of packaging, ensuring long-lasting performance.

- Ease of Use: Many carton sealers come with intuitive controls and require minimal training for operators.

- Safety Features: These machines are equipped with emergency stop buttons and protective covers, ensuring operator safety.

Applications of Carton Sealing Machines

Carton sealing machines are integral in many industries:

- E-commerce: Sealing product boxes quickly and securely for delivery.

- Food & Beverage: Packaging food items to ensure freshness and safety during transportation.

- Logistics & Warehousing: Sealing cartons in high volumes for distribution.

How to Maintain an Automatic Carton Sealing Machine

Regular maintenance is essential to ensure optimal performance. Key maintenance tasks include:

- Cleaning the machine: Dust and tape residues can accumulate, leading to reduced efficiency.

- Lubricating moving parts: This prevents wear and tear on the mechanical components.

- Checking the taping heads: Regularly inspect the taping heads for alignment and wear to ensure consistent sealing.

Conclusion

An automatic carton sealing machine is a crucial asset in any high-volume packaging operation. It improves efficiency, consistency, and reduces costs while ensuring that cartons are securely sealed for shipping. Investing in one of these machines, whether it’s paired with a Labeling Machine or other packaging equipment, can significantly enhance production workflows.