In the world of packaging and labeling, businesses often face challenges such as misalignment of labels, time-consuming manual application processes, and the risk of inconsistent results. These issues can lead to inefficiency, increased production costs, and frustrated employees. The solution to these problems?

A flag applicator is a highly efficient labeling machine designed to streamline the application process. By automating label placement with precision and speed, it ensures consistent, high-quality results for a wide range of products.

This article explores what a flag applicator is, how it works, and why it might be the perfect solution for your packaging needs.

What Is a Flag Applicator?

A flag applicator is a specialized type of labeling machine that applies labels in a flag-like manner. Unlike traditional labeling methods where labels are simply placed flat onto products, a flag applicator wraps labels around the product’s surface and secures them in place at a fixed point, creating a “flag” effect. This results in labels that are more visible and easy to read, especially on cylindrical or irregularly shaped products like bottles, cans, or wires.

Flag applicators are commonly used in industries that require high precision and high-speed labeling. These include industries like food and beverage, electronics, pharmaceuticals, and cosmetics, where brand identity, product information, and regulatory compliance are essential.

How Does a Flag Applicator Work?

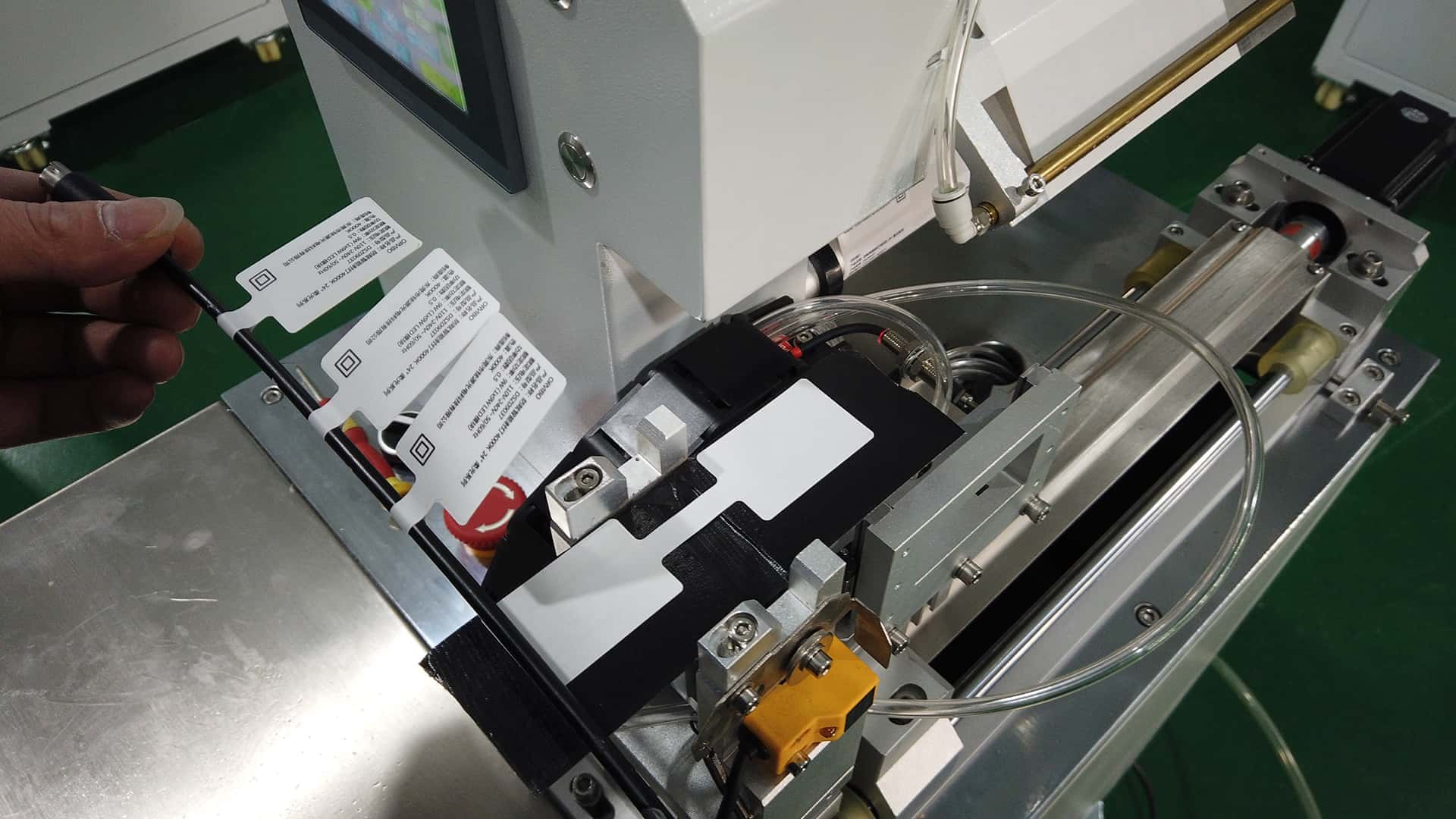

Flag applicators are designed with advanced automation to handle high-volume labeling tasks. They work by feeding the label through a mechanism that ensures proper alignment and placement. The core of the flag applicator system includes:

- Label Feeding Mechanism: Labels are unwound from a roll and pass through a tension-controlled system to maintain consistency.

- Label Positioning: Sensors and motors ensure that the label is correctly aligned with the product before being applied. This helps avoid misalignment and waste.

- Flag Folding Mechanism: The label is applied to the product in a precise manner, folding over at a predetermined position to create the flag effect.

The PLC (Programmable Logic Controller) in the flag applicator system coordinates these actions, ensuring that the label is applied at the right speed and with perfect precision.

Key Features of a Flag Applicator

Flag applicators are designed with several key features that make them ideal for high-efficiency labeling:

High Accuracy

With labeling accuracy typically within ±0.5mm, flag applicators ensure precise label placement. This high degree of accuracy minimizes waste and ensures that each label adheres exactly where it needs to, improving the overall quality of the product.

Versatility

Flag applicators are adaptable to different label sizes and product types. Whether you’re labeling bottles, wires, or cosmetic jars, a flag applicator can be customized to meet your needs. Some models even support corner wrap labeling machines for products with complex shapes.

Easy Operation

With user-friendly touchscreen controls, operators can easily set and adjust parameters such as labeling speed, position, and label size. This allows for seamless integration into existing production lines without the need for complex setups or manual adjustments.

Customization

Flag applicators can be customized to suit specific industry requirements. For instance, some models come equipped with additional features such as barcode printers for adding product identification or regulatory codes directly onto the labels.

Applications of Flag Applicators

Flag applicators are used across many industries where accurate and efficient labeling is critical. Some of the key applications include:

- Food and Beverage Industry: Labeling bottles, cans, and containers quickly and efficiently for compliance with regulations.

- Electronics: Labeling wires, cables, and small electronic components for tracking and brand identification.

- Pharmaceuticals: Applying clear and precise labels to medicine bottles and packaging for accurate product information.

For example, in the pharmaceutical industry, flag applicators are often used in combination with liquid filling machines to label vials and ampoules quickly and accurately.

Benefits of Using a Flag Applicator

Using a flag applicator in your labeling process can provide several important benefits:

Time Efficiency

Flag applicators drastically reduce the amount of time spent on labeling tasks. With automated label application, production lines can run faster, boosting overall throughput. This is especially important in high-volume industries like food packaging and beverage production.

Improved Label Durability

The flag folding technique not only ensures proper application but also helps the label adhere more securely to the product. This leads to improved durability, preventing the label from peeling off or becoming damaged during handling or transportation.

Consistency and Quality

With a flag applicator, you can achieve consistent results, regardless of the operator or environmental conditions. This results in high-quality labels that enhance the aesthetic appeal of the product and promote a professional image.

Cost Savings

By automating the labeling process, businesses can save on labor costs and reduce material waste. With accurate and precise label placement, the need for rework or discarded products is minimized.

How to Choose the Right Flag Applicator

When selecting a flag applicator for your business, there are a few important factors to consider:

- Label and Product Compatibility: Ensure that the applicator can handle the type of labels you plan to use and is suitable for the products you are labeling, such as bottles, flat labeling, or even customized labeling machines for unique shapes.

- Speed and Accuracy: Consider your production speed requirements. Flag applicators vary in labeling speed, with some capable of processing up to 35-50 labels per minute.

- Integration with Existing Systems: The flag applicator should integrate seamlessly with other machines in your production line, such as filling machines or shrink wrap machines.

- Maintenance and Support: Look for a flag applicator that offers easy maintenance and good customer support to ensure smooth operation over time.

Tips for Optimizing a Flag Applicator’s Performance

To get the most out of your flag applicator, consider the following tips:

- Regular Calibration: Ensure that the applicator is calibrated regularly to maintain labeling accuracy.

- Proper Label Material: Use high-quality labels that are compatible with the flag applicator to avoid issues such as label jamming or peeling.

- Operator Training: Train operators thoroughly to ensure that they understand how to use the machine and handle common issues like misalignment.

Conclusion

In summary, a flag applicator is an essential tool for businesses that require high-precision, high-speed labeling. Whether you are labeling bottles, food packaging, or industrial components, a flag applicator can streamline your labeling process, improve efficiency, and deliver consistent results. By investing in this advanced labeling machine, companies can enhance their production lines, reduce costs, and maintain a professional image in the marketplace.