Cold glue labelers have their own set of problems. They can be inconsistent, take a long time to set up, and slow down production. These problems can lead to wasted labels and production time. A cold glue labeling machine can solve those problems by giving you precise, efficient, reliable labeling that reduces waste and downtime.

A cold glue labeling machine uses a water-based adhesive to apply paper labels to various containers. These machines offer precise, reliable, and cost-effective labeling solutions for industries like food, beverage, and pharmaceuticals, supporting high-speed operations.

Now, let’s dive into the specific features, how they work, and the benefits.

What is a Cold Glue Labeling Machine?

A cold glue labeling machine applies paper labels to products using a water-based adhesive. The labeling machine coats the label with glue before applying it to the container. Unlike hot melt labeling, cold glue labeling is ideal for applications that require a slower drying time and more precise label positioning. It is commonly used in industries such as food, beverages, pharmaceuticals, and consumer goods.

These machines work well with paper labels and are often preferred for glass, plastic, or metal containers. They allow for high-speed production, where precision and durability are essential.

How Does a Cold Glue Labeling Machine Work?

Cold glue labeling machines operate by feeding labels from a stack, applying adhesive on the back, and placing them onto the container. The process involves several stages:

- Label Pick-Up: The machine picks up a label from the magazine.

- Glue Application: A roller applies a thin layer of glue to the label.

- Labeling: The label is pressed onto the container using rollers or other mechanisms to ensure even application.

- Drying: The glue gradually dries as the container moves along the production line.

This process ensures consistent label application with minimal waste and no thermal requirements, making it energy efficient.

Cold Glue Labeling vs. Hot Melt Labeling

The primary difference between cold glue and hot melt labeling is the type of adhesive used and the temperature required for application. Cold glue uses water-based adhesives applied at room temperature, making it suitable for heat-sensitive products or labels.

Advantages of Cold Glue Labeling:

- Precise label application for glass, plastic, and metal containers.

- More cost-effective, especially for high-volume production.

- No need for heating equipment, reducing energy consumption.

Advantages of Hot Melt Labeling:

- Fast adhesive drying time, supporting higher production speeds.

- Stronger adhesive properties for labels that require immediate bonding.

Key Components of a Cold Glue Labeling Machine

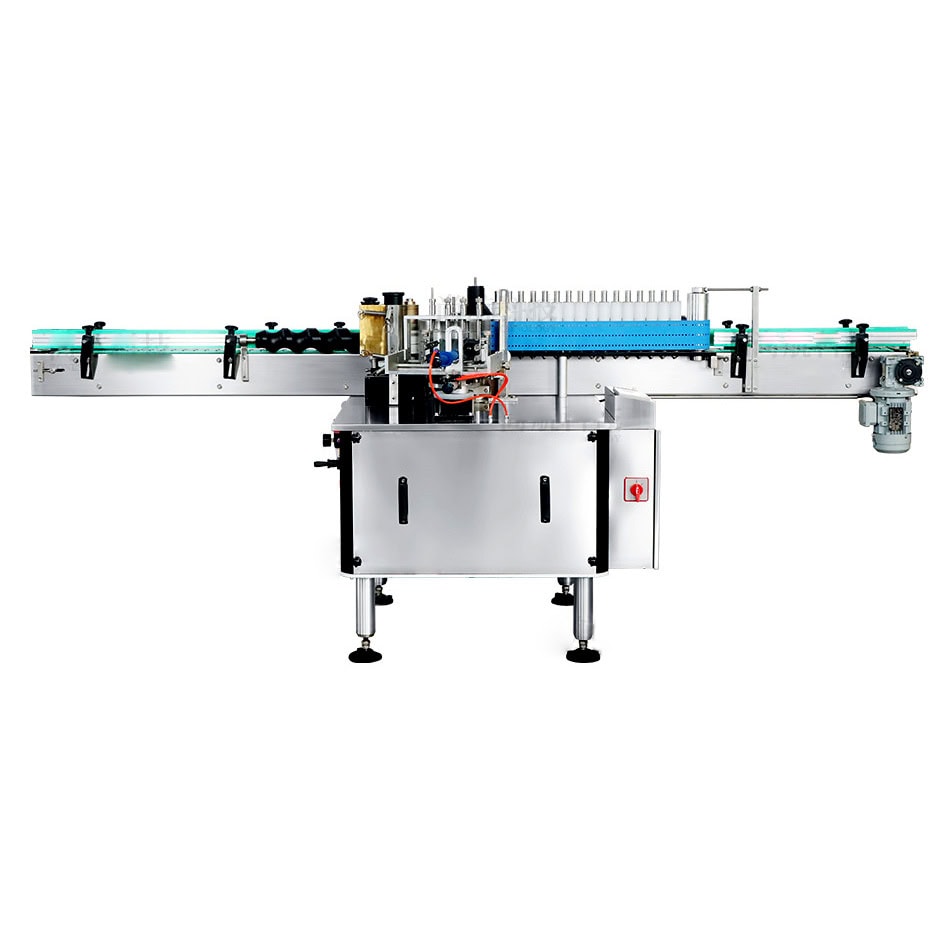

A cold glue labeling machine consists of several key components that ensure the smooth operation of labeling processes:

- Label Magazine: Holds the labels before application.

- Glue Application Unit: Applies the adhesive to the back of the label.

- Label Transfer Mechanism: Transfers the glued label to the container.

- Pressing Rollers: Ensures the label is evenly applied and bonded to the surface.

- Conveyor System: Moves the containers along the production line for seamless labeling.

Applications of Cold Glue Labeling Machines

Cold glue labeling machines are widely used in industries where high-speed, precision labeling is essential. Common applications include:

- Food and Beverage: Cold glue labels are ideal for glass bottles used in beer, wine, and soda production. The durability and water resistance of the glue make it suitable for refrigerated and wet conditions.

- Pharmaceuticals: In the pharmaceutical industry, cold glue labeling machines ensure that labels are securely applied to plastic or glass containers, even on small or irregularly shaped bottles.

- Consumer Goods: These machines are also used for labeling household products, cosmetics, and personal care items where label durability is essential.

Advantages of Cold Glue Labeling Machines

- Cost-Effectiveness: Cold glue labeling machines are more affordable than hot melt systems since they don’t require heating elements. The use of water-based adhesives is also more economical, especially for high-volume operations.

- Energy Efficiency: Without the need for heating components, cold glue labeling machines consume less energy, reducing operational costs.

- Precision: The slow drying nature of cold glue allows for adjustments during application, ensuring that labels are applied evenly without misalignment or air bubbles.

- Versatility: Cold glue systems are adaptable to a wide range of materials and product shapes, including glass, plastic, and metal containers.

Maintenance and Care

Regular maintenance is essential to keep cold glue labeling machines running smoothly. Key maintenance tasks include:

- Cleaning the glue rollers: Prevent adhesive buildup that could affect performance.

- Checking for glue consistency: Ensure the adhesive is applied evenly to avoid labeling errors.

- Lubricating moving parts: Keeps the machine operating efficiently by reducing wear and tear on components. Routine inspections and maintenance of these machines help extend their service life and reduce downtime.

Conclusion

Cold glue labeling machines offer a reliable, efficient, and cost-effective solution for applying paper labels in various industries, with advantages such as energy efficiency, precision, and versatility.