Several pharmaceutical companies have trouble making capsules by hand fast enough. This lack of capsule-filling speed hurts production and leads to inconsistent dosages of medicine in capsules. These problems can cause profitability issues and issues with the rules about making medicine. You should look at a Capsule Filling Machine to solve these problems.

A Capsule Filling Machine will fill the empty capsules with medicine or supplements. This makes the process faster. It gives you control over how much medicine is in each capsule. These machines are used in the pharmaceutical and nutraceutical industries.

Keep reading to learn how these machines work, the different types, why they are valuable, and how they increase the efficiency of production lines.

What is a Capsule Filling Machine?

A capsule filling machine is a specialized piece of equipment designed to automate the process of filling empty capsules with powder, granules, or liquids. These machines are widely used in pharmaceutical, supplement, and nutraceutical industries to ensure precise dosage and consistency. The capsules, typically made of gelatin or other materials, are separated, filled, and sealed in a single automated process, eliminating the risks of manual errors.

These machines are critical for maintaining the integrity of the product, especially in large-scale production where high accuracy and hygiene are essential. By utilizing a capsule filling machine, manufacturers can achieve high productivity, reduce labor costs, and minimize material waste.

Types of Capsule Filling Machines

Manual Capsule Filling Machine

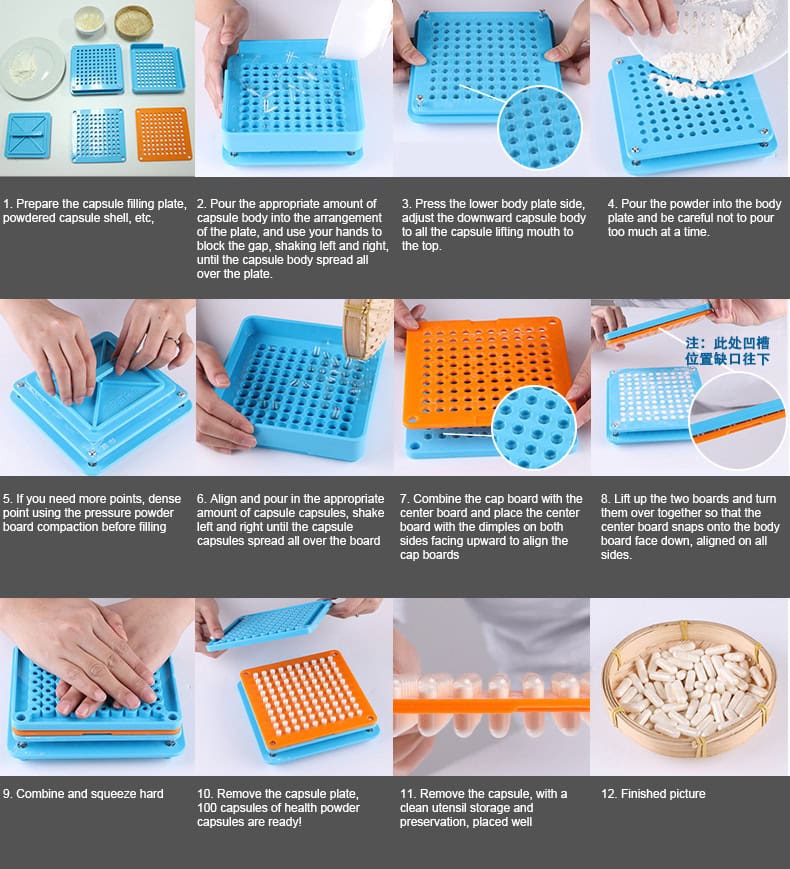

Manual capsule filling machines are used for small-scale production or laboratories. Operators manually load the capsules, fill them with the material, and then seal them by hand. These machines are best suited for low-volume production runs and can handle a variety of capsule sizes, making them flexible but labor-intensive.

Semi-Automatic Capsule Filling Machine

Semi-automatic machines combine some manual tasks with automation. They automate processes like capsule separation and filling, while still requiring manual input for loading and sealing. These machines offer a good balance between cost and efficiency, making them ideal for medium-scale production where flexibility and speed are both important factors.

Automatic Capsule Filling Machine

Fully automated capsule filling machines are the most efficient and suitable for large-scale production. They are capable of filling thousands of capsules per hour with minimal human intervention. Automated machines ensure the highest levels of precision and hygiene, reducing errors and maximizing productivity. These machines are commonly used in industries where bulk production is necessary, such as in pharmaceuticals and supplements.

Working Principle of a Capsule Filling Machine

The operation of a capsule filling machine follows these basic steps:

Capsule Separation

First, empty capsules are loaded into the machine, which then separates the capsule body from the cap. This is done automatically and with high precision to ensure smooth filling.

Dosing and Filling

The next step involves filling the body of the capsule with the desired material, which can range from powders to liquids. The machine uses precise dosing systems to ensure that each capsule contains the correct amount of substance, ensuring compliance with pharmaceutical standards.

Capsule Closing and Ejection

Once filled, the capsule cap is replaced and sealed. The filled capsules are then ejected from the machine and sent to the packaging or labeling stage.

Benefits of Capsule Filling Machines

Increased Efficiency

Capsule filling machines significantly speed up the production process. Automatic machines can produce thousands of capsules per hour, which is vital for meeting high demand in industries like pharmaceuticals and nutraceuticals.

Accuracy and Consistency

These machines ensure that every capsule is filled with the exact dosage, reducing the risk of under or overfilling. This level of precision is essential for regulatory compliance and ensuring the safety and effectiveness of the medication.

Cost-Effectiveness

Although capsule filling machines require a significant initial investment, they reduce labor costs by automating the process. Moreover, the increased speed and accuracy of these machines lead to fewer errors and less wasted material, ultimately lowering production costs.

Hygiene and Safety

By minimizing human contact, these machines reduce the risk of contamination. Automated systems often include built-in cleaning and sterilization features, further ensuring product safety.

Common Applications of Capsule Filling Machines

Capsule filling machines are widely used across several industries. The most common applications are in pharmaceuticals, where they fill capsules with active ingredients. In the nutraceutical industry, these machines are used to encapsulate dietary supplements, herbal extracts, and vitamins.

Many manufacturers integrate capsule filling machines with packaging machines to streamline production processes, moving seamlessly from filling to packaging without manual intervention. This improves both efficiency and output quality.

Advantages of Automatic Capsule Filling Machines

Automatic capsule filling machines offer several key advantages:

- High-Speed Production: These machines can fill thousands of capsules per hour, meeting the demands of large-scale production.

- Minimal Supervision: Automated systems require little oversight, reducing the need for skilled labor and minimizing costs.

- Flexibility: Capable of handling different capsule sizes and types, automatic machines are versatile enough to meet various production needs.

- Reduced Waste: These machines ensure that materials are used efficiently, reducing waste and saving costs in the long run.

Conclusion

Capsule filling machines are indispensable in modern pharmaceutical and supplement manufacturing. Whether manual, semi-automatic, or fully automatic, these machines offer efficiency, accuracy, and compliance, enhancing the overall production process and product quality.