In the world of packaging and automation, understanding the price of equipment is crucial. Whether you’re a small business owner or a large-scale manufacturer, the cost of an automatic labeling machine can significantly impact your budget. So, what determines these prices, and how can you make the best investment? Let’s delve into the key factors and considerations.

The price of automatic labeling machines is influenced by various factors, including machine type, features, and production capacity. Understanding these elements can help businesses make informed decisions. From entry-level to high-end machines, knowing what you’re paying for is essential for maximizing ROI.

For over two decades, I’ve been in the automation industry, and I’ve seen firsthand how these factors play out in the market. Here’s what you need to know.

What Factors Influence the Price of Automatic Labeling Machines?

The cost of an automatic labeling machine is determined by several factors. The most obvious is the type of machine. Different machines cater to various labeling needs—some are designed for specific label materials, while others are more versatile. Features like speed, precision, and the ability to handle multiple label sizes can also affect the price.

In addition, brand reputation plays a significant role. Well-known brands often charge more due to their established track record and reliability. However, this doesn’t mean lesser-known brands don’t offer good quality; it’s just that the market perception influences pricing. Lastly, production capacity—how many labels a machine can apply per minute—is a crucial factor. Higher capacity usually means a higher price tag.

What Are the Price Ranges for Different Types of Machines?

Automatic labeling machines come in various price ranges, depending on their capabilities and features. Entry-level machines, suitable for small businesses or startups, typically cost less. These machines are straightforward, with basic features and lower speeds. They’re great for businesses just starting out or with limited production needs.

Mid-range machines offer more features, like faster speeds and the ability to handle a variety of label types and sizes. They’re ideal for medium-sized businesses looking to scale up. High-end machines, on the other hand, come with all the bells and whistles—advanced technology, high speed, and the ability to integrate with other systems. These are perfect for large-scale operations that require efficiency and versatility. The cost, of course, is much higher, but the investment can pay off in the long run.

How Does Cost Compare to Value?

When it comes to buying an automatic labeling machine, cost versus value is a crucial consideration. It’s not just about how much you spend; it’s about what you get in return. A cheaper machine might seem like a good deal upfront, but it could cost more in the long run due to maintenance issues, downtime, and inefficiency. On the other hand, a more expensive machine may offer better durability, speed, and accuracy, leading to higher productivity and lower long-term costs.

In my experience, it’s essential to consider the total cost of ownership. This includes not just the purchase price but also installation, maintenance, and training. A machine that’s reliable and requires less frequent servicing can save a lot of money and headaches down the line.

What Should You Consider When Budgeting?

Budgeting for an automatic labeling machine requires careful planning. You need to consider not only the purchase price but also potential additional costs. Installation fees, maintenance contracts, and operator training can add up. It’s also wise to factor in the cost of spare parts and consumables, which can vary depending on the machine and the manufacturer.

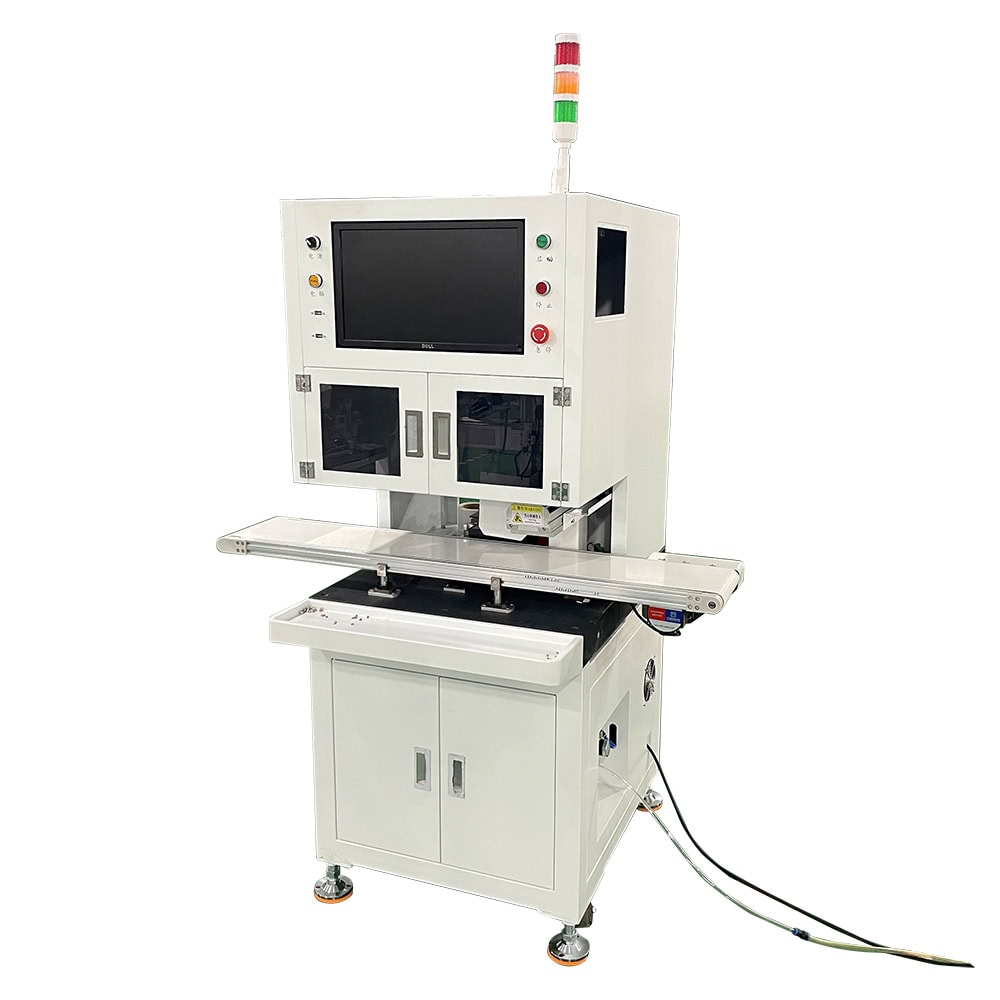

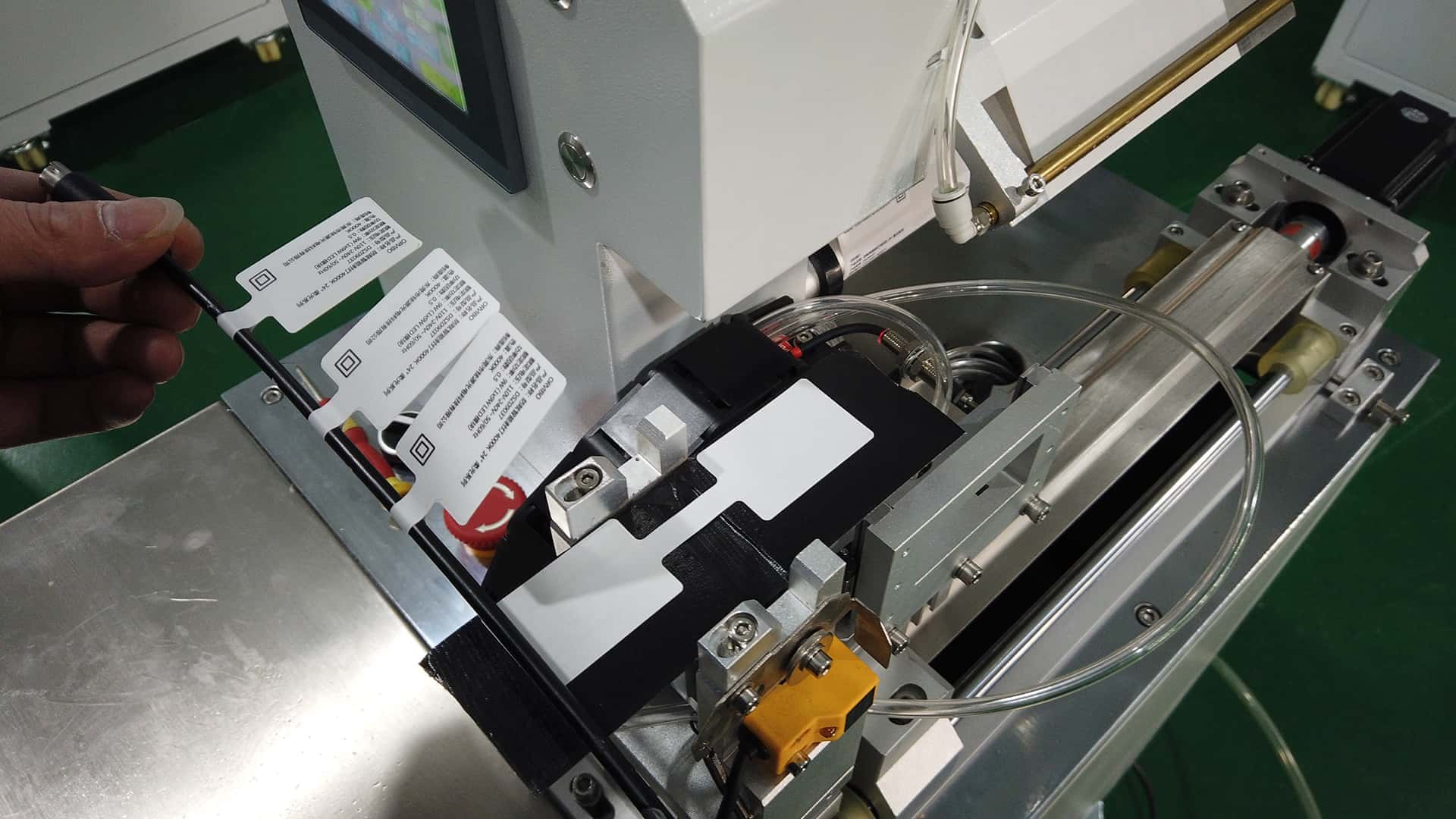

It is important to note that labeling accuracy is an important consideration in the price of the machine. High-precision labeling equipment is more expensive than regular-precision equipment. For example, our CCD Camera Visual Flat Labeling Machine is a high-precision equipment.

Are There Hidden Costs to Watch Out For?

When buying an automatic labeling machine, it’s crucial to be aware of hidden costs. One common hidden cost is the price of installation and setup. Some manufacturers include this in the purchase price, while others charge separately. Another potential cost is the training required for operators and maintenance staff. This is especially important if the machine has advanced features that require specialized knowledge.

Additionally, ongoing maintenance and repair costs can add up. It’s essential to understand the warranty terms and whether they cover parts and labor. Some machines may require specific consumables or spare parts that can only be sourced from the manufacturer, leading to higher expenses. Being aware of these potential hidden costs can help you budget more accurately and avoid surprises.

How Do Market Trends Affect Prices?

The automatic labeling machine market is influenced by various trends that can impact prices. For instance, advancements in technology often lead to new features and capabilities, driving up costs. On the flip side, as older models become obsolete, they may be available at a discount. Market demand also plays a role; high demand for certain types of machines can drive prices up, while a saturated market can lead to competitive pricing.

Another factor is the global economic environment. Supply chain disruptions, changes in raw material prices, and economic downturns can all affect machine prices. For example, during times of economic uncertainty, manufacturers may offer promotions or discounts to encourage sales. Keeping an eye on market trends can help you time your purchase to get the best deal.

How Can You Get the Best Deal?

Getting the best deal on an automatic labeling machine involves more than just finding the lowest price. It’s about finding the right machine for your needs at a fair price. One way to do this is by negotiating with suppliers. Don’t be afraid to ask for discounts, especially if you’re buying in bulk or purchasing additional equipment. Another strategy is to buy directly from the manufacturer, which can sometimes result in lower prices compared to distributors.

Timing your purchase can also make a difference. Some companies offer end-of-year discounts or promotions during trade shows. Additionally, consider buying refurbished or demo units, which can offer significant savings. Just make sure to verify the machine’s condition and warranty. Lastly, always do your research and compare prices from different suppliers to ensure you’re getting the best deal.

What Should You Consider from Customer Experiences?

Customer experiences and testimonials can provide valuable insights into the pricing and value of automatic labeling machines. Hearing from other businesses that have purchased and used the equipment can help you understand the practical aspects, such as ease of use, reliability, and after-sales support. Look for reviews that mention the machine’s performance, any issues encountered, and how the manufacturer handled them.

In my years in the industry, I’ve seen how positive customer experiences can influence purchasing decisions. A manufacturer with a strong reputation for quality and support is often worth the extra cost. It’s also useful to visit customer sites if possible, to see the machine in action and talk to operators. This firsthand experience can provide a clearer picture of what to expect.

Conclusion

In conclusion, the price of an automatic labeling machine depends on various factors, from the type and features of the machine to market trends and customer experiences. Understanding these factors can help you make an informed decision and ensure you get the best value for your investment.

That’s it for this overview of automatic labeling machine prices. If you have any questions or need further information, feel free to reach out.