If you label a box wrong, you can have all kinds of problems. You can have shipments delayed, products rejected, and be fined by regulatory agencies. These issues can cost you business and make your customers mad. You need automatic box labeling machines.

There are many kinds of automatic box labeling machines. There are inline, top, bottom, corner, side, wrap-around, print-and-apply, and pallet labelers. Each one does something different to help you be more efficient and accurate.

Choosing the right labeling machine is critical for ensuring production efficiency and maintaining regulatory compliance.

Inline Labeling Machines

Inline labeling machines put labels on boxes as they go down a conveyor. These are for high-speed operations where you need to label all the time. These are great for high-volume industries like food and beverage or pharmaceutical packaging.

Benefits:

- Efficient for high-speed production lines.

- Can label multiple sides of a box in one pass, increasing throughput.

Inline labeling systems offer versatility, as they can be easily integrated into existing conveyor systems. Their ability to handle various label sizes and shapes makes them ideal for mass production.

Top and Bottom Labeling Machines

Top and bottom labeling machines are designed to apply labels to either the top or the bottom surface of a box. This type of labeling machine is highly adaptable and can handle various box sizes, making it suitable for industries that require different surfaces to be labeled, such as shipping, e-commerce, or consumer goods.

Applications:

- Top labeling is commonly used for branding or product information.

- Bottom labeling is often used for barcodes or tracking purposes.

Benefits:

- Allows for flexible labeling on multiple surfaces.

- Supports varying label sizes, making it ideal for different product types.

Top and bottom labeling machines ensure that vital product information is visible from different angles, enhancing consumer experience and compliance with shipping standards.

Corner Wrap Labeling Machines

Corner wrap labeling machines are unique in that they apply labels to two adjacent sides of a box, wrapping around the corner. This technique is especially useful for tamper-evident seals and for providing clear visibility of labels from multiple sides.

Benefits:

- Ideal for tamper-evident packaging.

- Ensures seamless label visibility on multiple surfaces.

Corner wrap machines are frequently used in the pharmaceutical, logistics, and food industries, where secure and visible labeling is critical to product integrity and safety.

Side Labeling Machines

Side labeling machines are specifically designed to apply labels to one or both sides of a box. This type of machine is perfect for industries that require clear side labeling for identification or branding, such as beverage cartons or industrial packaging.

Benefits:

- Great for branding or product identification from the side.

- Suitable for large, bulky packages or shipping cartons.

Side labelers are particularly useful in ensuring that products on store shelves or in warehouses are easily identifiable and properly branded, reducing confusion and improving customer experience.

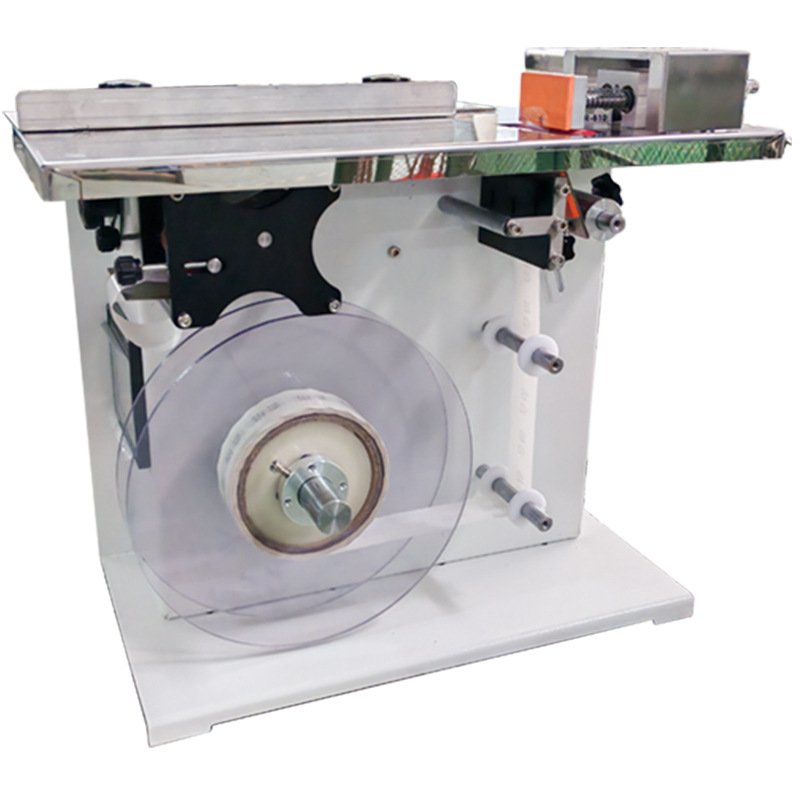

Wrap-Around Labeling Machines

Wrap-around labeling machines apply labels that completely encircle the product or box, providing 360-degree coverage. This type of labeling is ideal for round or cylindrical products but can also be used for multi-surfaced packaging.

Applications:

- Frequently used in industries that require full branding and compliance information around the entire product.

- Ideal for cylindrical or rounded packages, such as bottles or tubes.

Benefits:

- Provides full coverage, ensuring all sides of the product are branded or labeled.

- Ensures that compliance information is visible no matter how the package is positioned.

Wrap-around machines are often used in beverage, cosmetics, and household goods packaging, where complete product labeling is necessary for consumer transparency and legal requirements.

Print-and-Apply Labeling Machines

Print-and-apply labeling machines allow for real-time label printing and application, making them highly suitable for environments where information such as batch numbers, expiration dates, or barcodes must be updated frequently.

Benefits:

- Customizable labels can be printed on demand.

- Ensures accurate and timely labeling for regulatory compliance.

Print-and-apply systems are commonly used in industries such as pharmaceuticals, logistics, and food processing, where product information frequently changes or needs to be serialized for tracking purposes.

Pallet Labeling Machines

Pallet labeling machines are designed to apply labels to larger boxes or multiple boxes stacked together on a pallet. These machines can label one or more sides of the pallet, making them ideal for warehouse and logistics environments where automated inventory systems are used.

Benefits:

- Suitable for large-scale packaging and logistics operations.

- Ensures that palletized goods are properly labeled for tracking and shipment.

Pallet labelers are often integrated into large-scale production lines and provide the necessary automation for tracking goods as they move through the supply chain.

Label Sensors for Box Labeling Machines

Label sensors are a critical component of any automatic box labeling machine. These sensors detect the precise position of the label to ensure accurate application every time. There are several types of sensors used in automatic labeling machines, including optical sensors, capacitive sensors, and ultrasonic sensors.

Benefits:

- Accurate label placement reduces errors and waste.

- Ensures consistent labeling across all boxes.

Sensors help automate the labeling process by accurately detecting the product and label position, ensuring that every box is labeled correctly.

Customizable Labeling Machines

For industries with specific requirements, many manufacturers offer customizable labeling machines. These machines can be tailored to meet unique labeling needs, such as integrating barcode scanners or applying tamper-evident labels.

Applications:

- Used in pharmaceutical, food, and high-tech industries that require specialized labeling solutions.

- Allows for additional features such as tamper-evident or security seals.

Benefits:

- Customizable solutions ensure that even the most complex labeling needs are met.

- Tailored to meet industry-specific regulations and product requirements.

Customizable machines are ideal for companies looking for a unique labeling solution that meets strict compliance standards while providing flexibility in label design and placement.

Maintenance and Troubleshooting

Maintaining automatic labeling machines is crucial for ensuring consistent performance. Regular cleaning, sensor calibration, and alignment checks are necessary to avoid downtime and ensure labeling accuracy.

Common Issues:

- Misaligned labels or sensors.

- Mechanical jams or label wastage.

Solutions:

- Implement preventive maintenance strategies.

- Regularly clean sensors and check label alignment.

Routine maintenance keeps the machines running smoothly, avoiding costly repairs and ensuring that production deadlines are met.

Conclusion

Automatic box labeling machines are essential tools for improving packaging efficiency and ensuring accurate labeling across industries. Choosing the right machine for your production line—whether inline, print-and-apply, or customizable—can greatly enhance operational performance and ensure compliance with industry standards.