Labeling machines can have low accuracy, which means the labels can be off-center or different from one to the next. This makes the bottles look terrible and can affect the confidence people have in your product. You can do a few things to fix this.

The main reasons for low labeling accuracy of bottle labeler machines include sensor misalignment, incorrect calibration, and improper bottle feeding.

Keep reading to find out more about how those things add up to create problems.

Misalignment of Sensors

The sensors in a labeling machine play a crucial role in detecting the position of bottles and labels. If the sensors are not properly aligned, they can misinterpret the position of the label or bottle, leading to off-center labels or gaps between the label and bottle surface.

- Impact of Sensor Misalignment: A misaligned sensor can cause the label to be applied either too early or too late in the process. This results in inconsistent label placement on the bottle.

- Causes of Sensor Misalignment: This often occurs due to mechanical vibrations during operation, improper installation, or lack of regular adjustments.

Inconsistent Label Placement

Inconsistent label placement is a common issue that results in varying label positions on each bottle, leading to an unprofessional appearance. This can be caused by several factors.

- Bottle Size and Shape: Bottles of irregular shapes or sizes can shift during the labeling process, causing labels to be applied inconsistently.

- Label Roll Tension: If the tension in the label roll is not properly maintained, the labels may not dispense evenly, leading to inconsistent placement.

Incorrect Calibration of Labeling Machine

Calibration ensures the machine is correctly configured for the specific bottle and label sizes being used. Without proper calibration, the machine may apply labels inaccurately.

- Calibration Errors: Incorrect calibration often leads to labels being placed too high or too low on the bottle, or even at a slant.

- Solution: Regular calibration checks are necessary to ensure the machine is set correctly for the product being labeled.

Quality of Labels and Adhesives

The quality of labels and adhesives used in the process significantly affects labeling accuracy. Poor quality materials can lead to wrinkles, bubbles, or labels not adhering properly.

- Impact of Poor Quality Labels: Labels made from inferior materials may not stick well, leading to peeling or misalignment.

- Incompatible Adhesives: Using adhesives that are not compatible with the bottle material can also lead to poor labeling results, as the label may not adhere evenly.

Speed Settings of the Machine

The speed at which the labeling machine operates can greatly influence its accuracy. If the machine is set to run too quickly, it may not have enough time to properly place each label on the bottle.

- High-Speed Operation: When running at high speeds, the machine may experience mechanical strain, leading to slippage or misalignment of labels.

- Recommended Speed Settings: Adjusting the speed to a more moderate pace can improve accuracy and reduce the likelihood of errors.

Mechanical Wear and Tear

Over time, mechanical components in a labeling machine can wear out, affecting its performance. Worn parts may lead to decreased accuracy in label placement.

- Worn Components: Key components such as rollers, belts, and motors can degrade with use, leading to mechanical inaccuracies.

- Preventive Maintenance: Regular maintenance is essential to replace worn parts and ensure smooth operation, which directly impacts labeling accuracy.

Improper Bottle Feeding

Consistent bottle feeding is critical for accurate labeling. If bottles are fed into the machine irregularly or at different angles, it can result in labels being applied incorrectly.

- Misalignment of Bottles: If the bottles are not properly aligned when entering the labeling station, the labels will not be placed correctly.

- Solutions: Implementing a bottle feeding system that ensures consistent alignment and spacing of bottles can help improve accuracy.

Environmental Factors

Environmental conditions, such as temperature, humidity, and vibrations, can negatively impact the accuracy of a labeling machine.

- Impact of Environmental Conditions: Extreme temperatures can affect the adhesives on labels, while high humidity can cause labels to wrinkle or not stick properly.

- Controlled Environment: Operating the machine in a stable, controlled environment can help mitigate these issues and improve labeling accuracy.

Operator Error and Training Gaps

Even with well-maintained machines, operator error can still lead to poor labeling accuracy. Inexperienced operators may not fully understand the machine’s settings or how to troubleshoot common issues.

- Impact of Operator Error: Misconfigured settings or improper handling of the machine can result in misaligned labels.

- Solution: Proper training is essential to ensure operators understand how to use the machine correctly and can troubleshoot minor issues that may arise during operation.

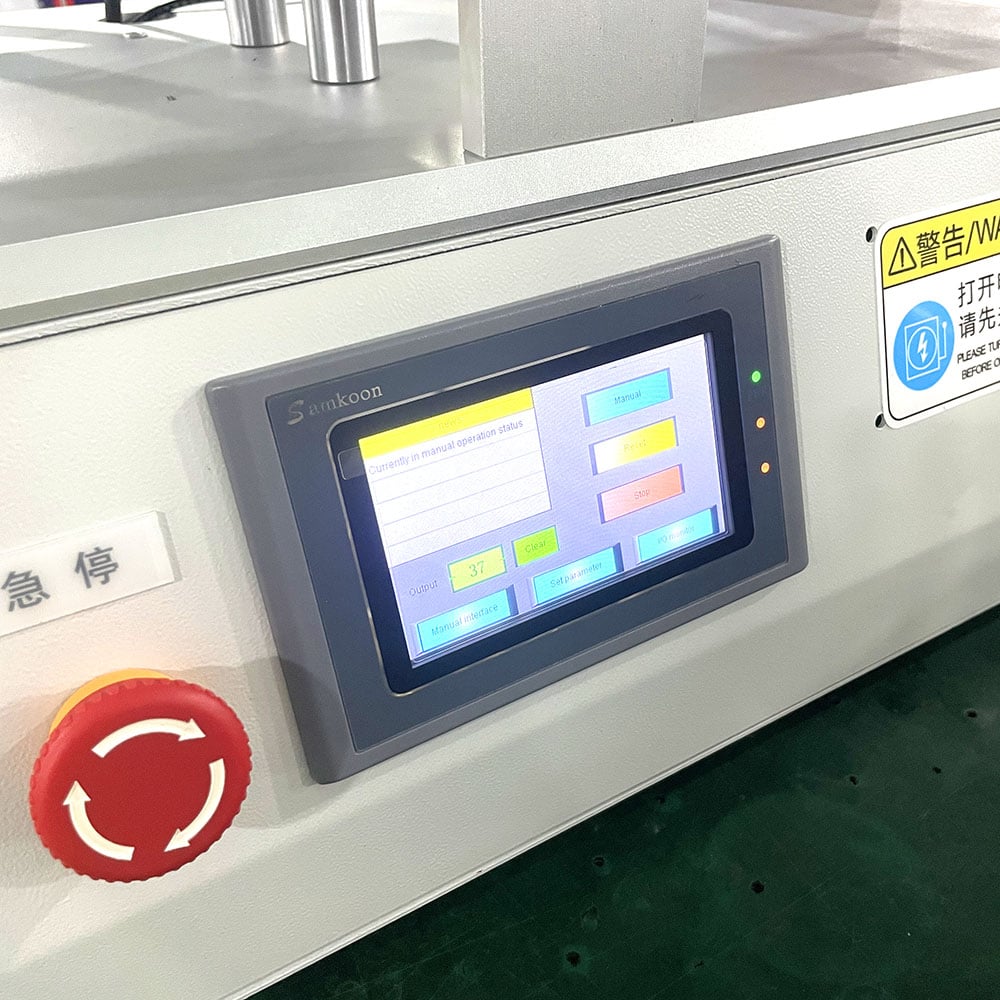

Software and Control System Malfunctions

Malfunctions in the software or control system of the labeling machine can also cause labeling errors. These malfunctions may include issues with the timing of label application or the synchronization between different parts of the machine.

- Common Malfunctions: Software glitches or improper system updates can cause the labeling process to malfunction, leading to misaligned or missed labels.

- Preventive Measures: Regular software updates and system checks can help prevent these issues and ensure the machine runs smoothly.

Labeling Machine Overload

Overloading the labeling machine by running it for extended periods or exceeding its capacity can cause mechanical strain, reducing labeling accuracy.

- Effects of Overload: Running the machine beyond its recommended capacity can lead to errors in label placement as the machine struggles to keep up with the demand.

- Solution: Adhering to the machine’s operational limits and allowing it sufficient downtime can help maintain labeling accuracy.

Troubleshooting and Maintenance Best Practices

To maintain optimal labeling accuracy, it’s important to implement regular maintenance and troubleshooting practices. Addressing issues early can prevent more serious problems down the line.

- Preventive Maintenance: Regularly inspect and clean machine components to ensure they are in good working condition.

- Common Troubleshooting Tips: Identify and resolve common issues like sensor misalignment, mechanical wear, or software malfunctions promptly to maintain high labeling accuracy.

Conclusion

Low accuracy in labeling machines can come from a few different things: the sensor gets knocked out of whack, it’s not calibrated correctly, something’s wearing out, or somebody screws up. You can fix all of these things.