Choosing the right labeling machine is essential for maximizing efficiency and precision in labeling operations. Without the right machine, companies face slow production times, inconsistent labels, and costly mistakes. The solution lies in selecting the right labeling machine to fit your production needs.

Labeling machines can be classified into automatic, semi-automatic, and manual types, as well as machines designed for specific applications such as round bottles, flat surfaces, and corner wraps. Each type serves a distinct purpose, catering to different product shapes and production scales.

In the following sections, we will explore the main types of labeling machines and how to choose the best one for your specific needs.

Automatic Labeling Machines

Automatic labeling machines are designed for large-scale operations, where speed and precision are critical. These machines handle the entire labeling process, from applying the label to ensuring proper alignment and placement, without requiring much human intervention. Ideal for industries such as food, beverage, and cosmetics, automatic labeling machines are perfect for companies that need to label hundreds or thousands of products per day.

These machines are compatible with various product types, including bottles, cans, and containers. Automatic labeling machines ensure high precision, with some models offering features like barcode printing or label verification, reducing the risk of labeling errors.

Semi-Automatic Labeling Machines

Semi-automatic labeling machines offer more control for operators, making them suitable for businesses with smaller production runs or those that frequently switch between different product lines. Unlike automatic machines, semi-automatic labeling systems require operators to manually position the product or initiate the labeling process, which offers greater flexibility.

Semi-automatic machines are commonly used for Bottle Labeling Machines and Flat Labeling Machines, where precise alignment is critical but production volumes do not justify the expense of fully automated systems. These machines are typically more affordable than their fully automatic counterparts, making them a great choice for small to medium-sized businesses.

Manual Labeling Machines

Manual labeling machines are ideal for small-scale operations or businesses that need a low-cost solution for labeling products. These machines are operated by hand, making them slower than automatic or semi-automatic options, but they are still efficient for companies that don’t require high-speed production.

While manual labeling machines lack the automation of other systems, they are perfect for startups or companies producing low-volume products. Flag Labeling Machines or Customized Labeling Machines often fall into this category, allowing businesses to customize their labels without investing in expensive equipment.

Round Bottle Labeling Machines

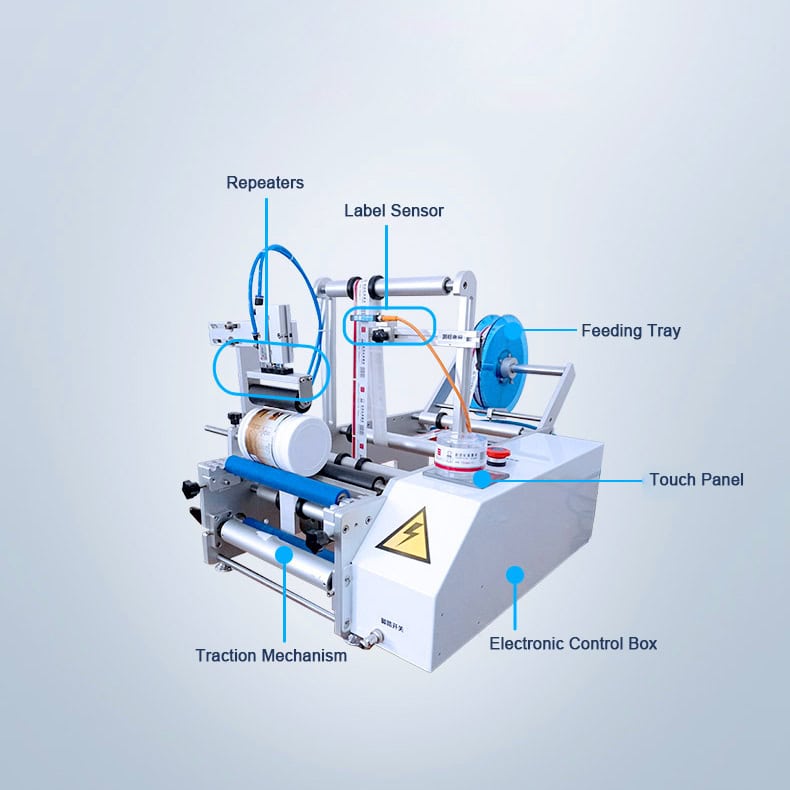

Round bottle labeling machines specialize in applying labels to cylindrical products like bottles, tubes, and jars. These machines are essential in industries such as food and beverage, cosmetics, and pharmaceuticals. They ensure that labels are applied evenly around the product, often with the option for single or double labels.

These machines are available in automatic, semi-automatic, and manual versions, depending on the production scale. Advanced models offer features such as label sensors, ensuring the label is correctly applied without human intervention.

Flat Surface Labeling Machines

Flat surface labeling machines are used for labeling products with flat surfaces, such as boxes, cartons, or electronic devices. These machines can handle a wide variety of products and label sizes, making them versatile in industries like packaging, consumer goods, and electronics.

With Flat Labeling Machines, businesses can expect precise application, smooth operation, and minimal label waste. These machines can be integrated into existing production lines, offering an efficient solution for high-volume flat surface labeling.

Corner Wrap Labeling Machines

Corner wrap labeling machines are designed to apply labels that wrap around the edges of products, such as cartons or boxes. This type of labeling is common in logistics and retail packaging, where shipping labels or product information needs to be applied to multiple sides of a package.

Corner wrap Labeling Machines provide an efficient solution for businesses needing to apply labels across two or more sides of a product, ensuring labels are easily readable and securely attached.

Top and Bottom Labeling Machines

Top and bottom labeling machines are used for products that require labeling on both the top and bottom surfaces. These machines are common in the food and packaging industries, where branding or product information needs to be visible from different angles.

Top and bottom labeling machines are typically part of automatic systems, ensuring high-speed production with consistent accuracy. The dual-labeling capability saves time and increases efficiency by eliminating the need for separate labeling processes.

Front and Back Labeling Machines

Front and back labeling machines are perfect for products that require labeling on two sides, such as bottles and jars. These machines apply labels to both the front and back of a product simultaneously, making them ideal for the beverage, personal care, and cleaning industries.

By using a Bottle Labeling Machine with front and back capabilities, companies can save time and reduce production costs. These machines ensure precise placement of labels, which is especially important for maintaining brand consistency across product lines.

Wrap-Around Labeling Machines

Wrap-around labeling machines apply labels that cover the entire circumference of a product, making them ideal for items like cans, jars, and bottles. These machines are commonly used in the food and beverage industry, where full product labeling is necessary for branding and regulatory compliance.

Wrap-around Bottle Labeling Machines offer high-speed operation and are compatible with various product sizes, ensuring accurate label placement even in large-scale operations.

Heat Shrink Labeling Machines

Heat shrink labeling machines apply shrinkable labels that conform tightly around a product when heat is applied. This method is commonly used in the beverage industry for full-body labeling or tamper-evident seals. The shrink label wraps around the product, providing 360-degree coverage for branding and product information.

Heat shrink machines are versatile and can accommodate a wide range of product shapes and sizes, making them a popular choice for businesses looking for high-impact packaging solutions.

Conclusion

Choosing the right labeling machine is crucial for ensuring efficiency and accuracy in production. Whether your business requires automatic systems for high-volume labeling or manual machines for smaller operations, understanding the different types of labeling machines will help you make an informed decision.